A mechanically controlled reverse circulation check valve

A mechanical control and reverse circulation technology, applied in the direction of wellbore/well valve device, production fluid, wellbore/well components, etc., can solve the problems of unusable oil and gas wells, narrow use range, complicated operation, etc., and achieve reliable sealing , simple operation, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

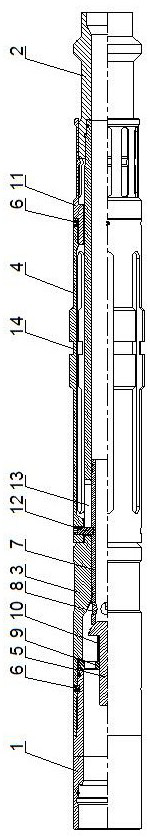

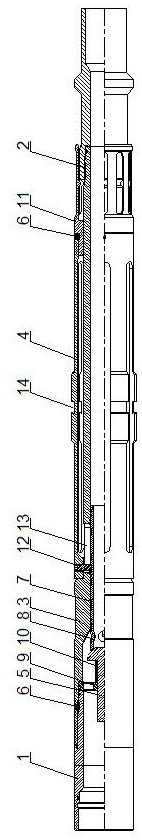

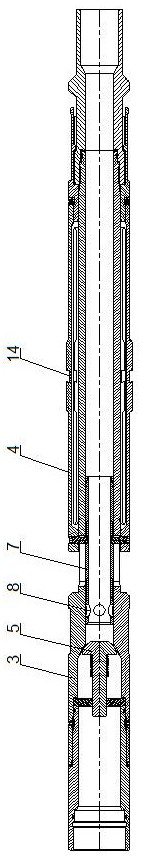

[0021] The mechanically controlled reverse cycle check valve consists of an upper joint 1, a lower joint 2, a mandrel 3, an indicating claw 4 and a valve body 5. One end of the mandrel 3 is threaded with an upper joint 1, and the upper joint 1 and the mandrel 3 Set screws 6 are used to limit the position in the circumferential direction; the upper joint 1 and the mandrel 3 are kept sealed by a sealing ring. The other end of the mandrel 3 is screwed with a lower joint 2; a sealing ring is arranged between the lower joint 2 and the mandrel 3. The mandrel 3 is a tubular body, and the central part of the mandrel 3 is provided with a stepped central hole through hole. A ball seat 7 is movably installed in the mandrel 3, and the ball seat 7 is a tubular body, and the circumference of one end of the ball seat 7 is evenly distributed with flow holes 8. The core shaft 3 at one end of the ball seat 7 is provided with a deflector 9, which is disc-shaped, and the central part of the defl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com