Dry and dense resonance method for reinforcing soft soil foundation of new hydraulic-fill sand

A technology of weak foundation and dense resonance method, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of high water content, mud wall protection, mud upwelling, etc. Small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

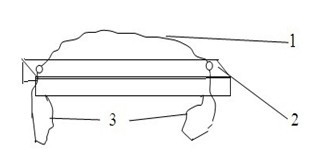

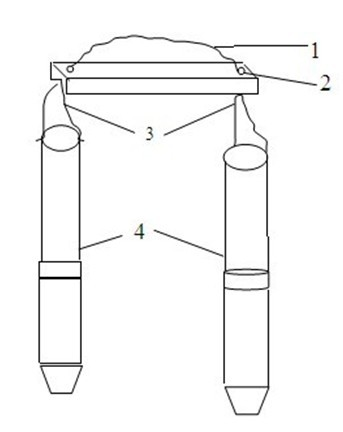

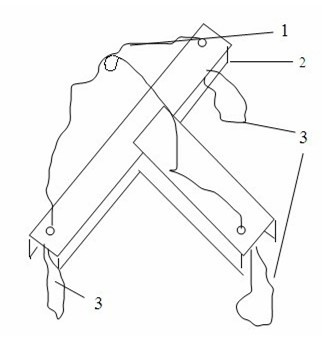

Image

Examples

Embodiment Construction

[0042] The present invention relates to a "dry-dense resonance method" for new dredging sand soft foundation reinforcement, and the method includes the following process steps:

[0043] 1. Preliminary preparation

[0044] 1. Determine the resonance area

[0045] To form resonance, it must be determined according to the excitation frequency of the vibrator, the range of excitation influence during the resonance process, and the reinforcement depth required by the design;

[0046] 1.1 Influence range of excitation during resonance

[0047] Generally, a single set of 30KW vibrator has an excitation influence range of 1.0m and a resonance range of 2.0m; a 45KW single set of vibrator has an excitation influence range of 1.25m and a resonance range of 2.5m;

[0048] The 75KW single-set vibrator has an excitation influence range of 1.5m and a resonance range of 3.0m.

[0049] 1.2. During the resonance process, the excitation affects the reinforcement depth

[0050] Generally, the 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com