Reference detecting device of automatic drilling and riveting system of airplane components and detecting method thereof

A technology for automatic drilling and riveting, aircraft parts, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of slow image transmission and processing speed, large memory, unfavorable online detection, etc., to improve the drilling and riveting accuracy and solution speed The effect of fast and high-precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

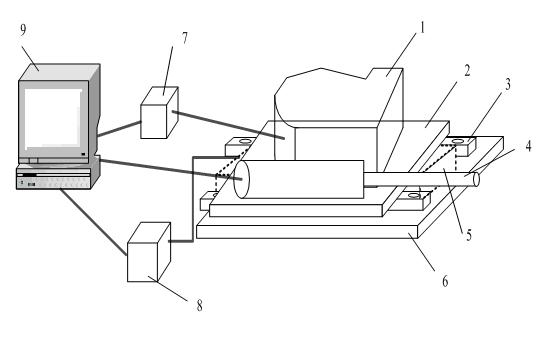

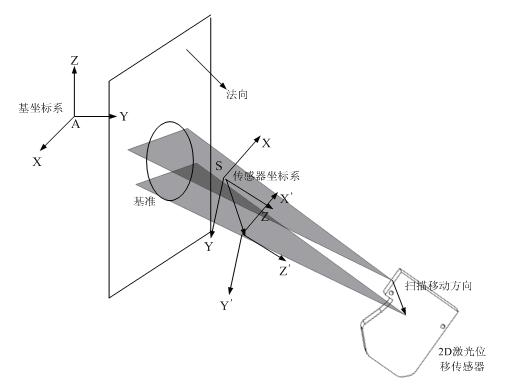

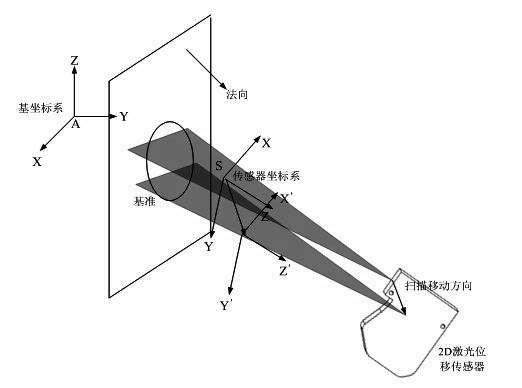

[0037] Such as figure 1 As shown, a reference detection device of an automatic drilling and riveting system for aircraft parts is used for detecting the reference actual positions of four reference holes on a product, and the four reference holes are located in the same plane or in an approximate plane, including a processor 9 , the controller 7 of the 2D laser displacement sensor, the controller 8 of the linear driver and the base 6, the base 6 is provided with a slider guide rail 3 and a linear driver 5, and the slider guide rail slide 3 is connected with a connecting plate 2 , and the linear driver 5 is connected with the connecting plate 2 for sliding the connecting plate 2 on the slider guide rail 3; the connecting plate 2 is provided with a 2D laser displacement sensor 1 and a distance sensor 4, and the processor 9 passes the 2D The controller 7 of the laser displacement sensor controls the 2D laser displacement sensor 1 to scan and measure the two-dimensional coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com