Closed-loop calibration method of micro-mechanical gyroscope inertial measuring component

A technology of inertial measurement components and micromechanical gyroscopes, which is applied in the calibration field of strapdown inertial navigation systems, and can solve problems such as inability to correct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

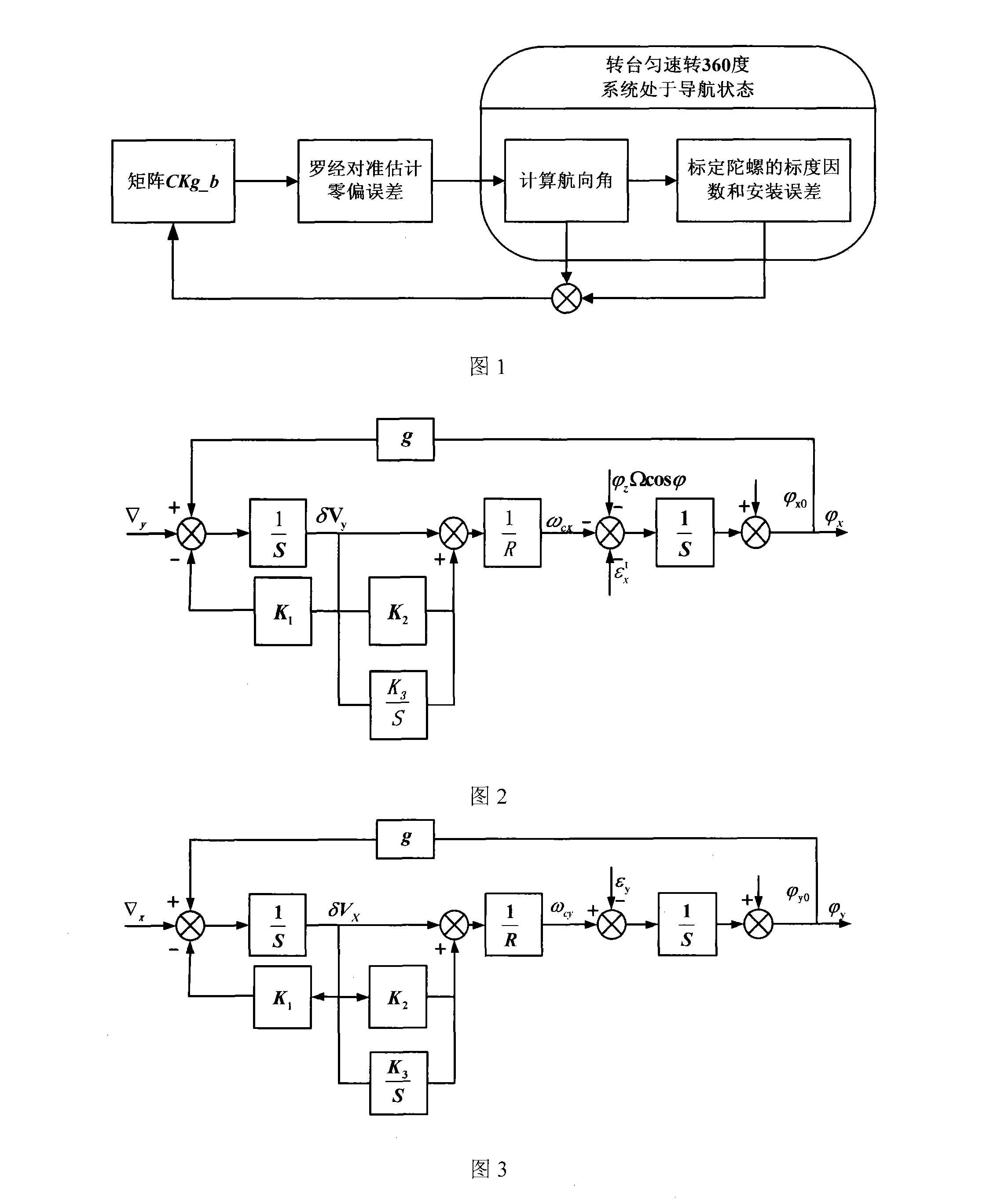

[0078] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0079] Step 1. Place the micromechanical gyro measurement component on the turntable. The main shafts of the X, Y and Z axis gyroscopes of the gyro measurement component are respectively parallel to the rotation axes of the inner, middle and outer frames of the turntable. The strapdown inertial navigation system is warmed up, and then the data output by the gyroscope and accelerometer are collected. The warm-up time is set according to the specific system.

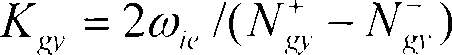

[0080] Step 2. Operate the turntable to adjust the strapdown inertial navigation system to the local geographic coordinate system, and then raise the Y axis to the north by an angle, which is equal to the latitude value Align the positive direction of the Y-axis with the positive and negative directions of the earth's rotation angular rate, and record the original output of the gyroscope N g + , N g - . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com