Gallium nitride based LED epitaxial substrate and preparing process thereof

A light-emitting diode, gallium nitride-based technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult control of the manufacturing process, high equipment and process requirements, and insignificant increase in reflectivity, etc., to achieve easy manufacturing process The control and preparation methods are simple and diverse, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples illustrate the preparation method of gallium nitride-based light-emitting diode epitaxial substrates,

[0031] Embodiment 1 of the preparation method of gallium nitride-based light-emitting diode epitaxial substrate includes the following steps:

[0032] (1) On a 2-inch C-plane sapphire substrate, a 1.5um silicon dioxide film is grown by chemical vapor deposition, such as figure 1 shown;

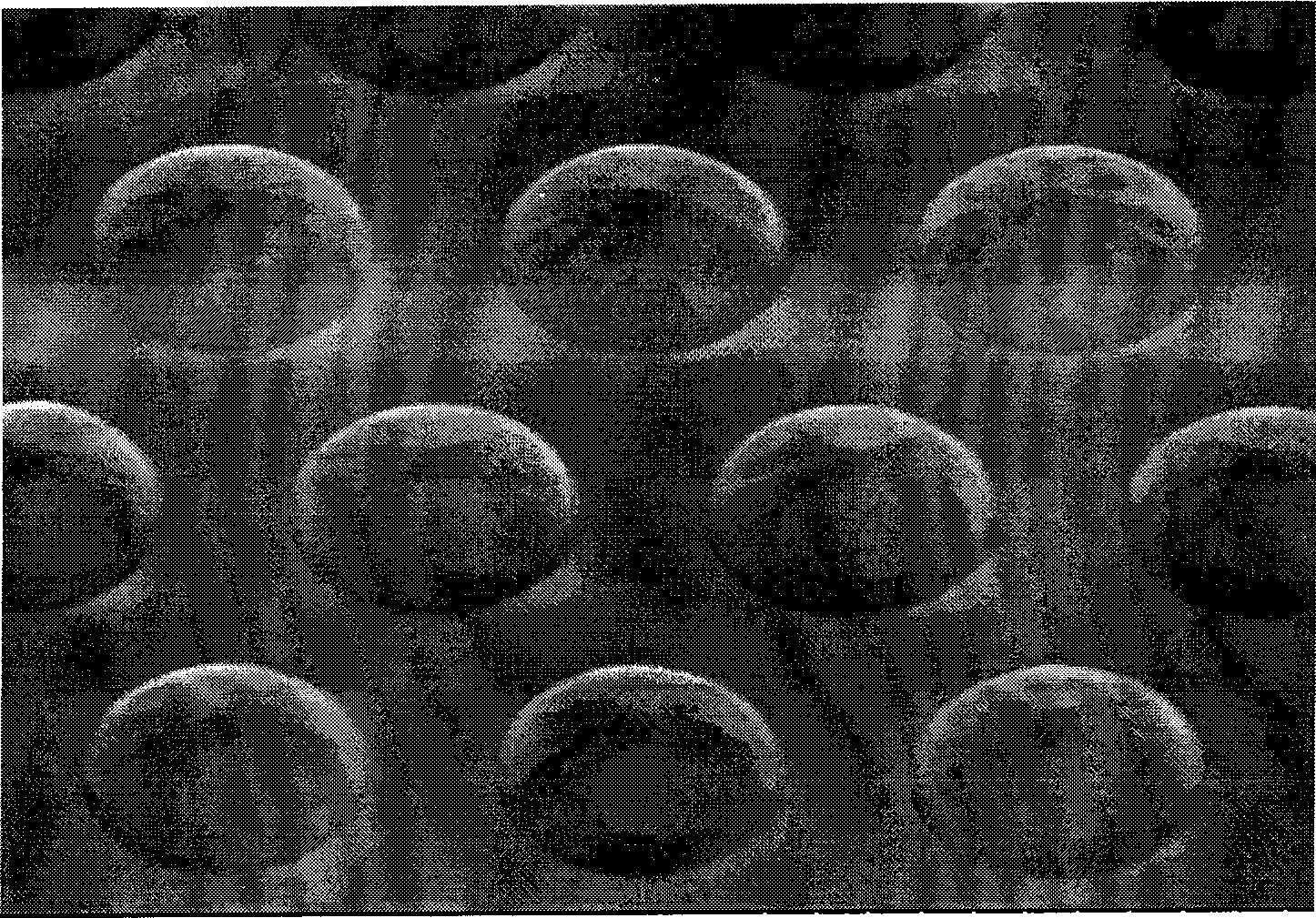

[0033] (2) Prepare a hemispherical mask on the silicon dioxide film with photoresist, such as figure 2 shown;

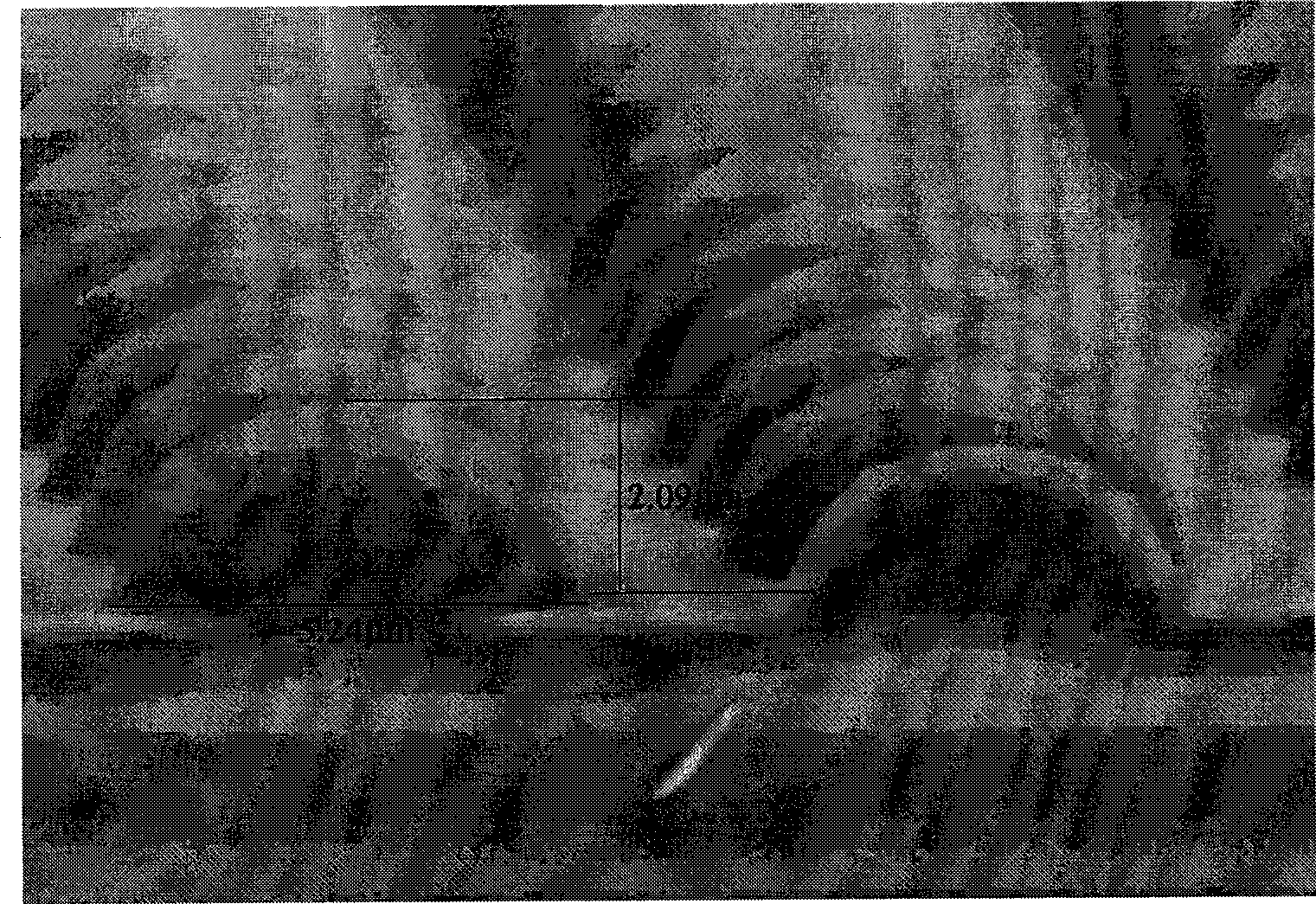

[0034] (3) By dry etching, the hemispherical photoresist mask pattern is transferred to the silicon dioxide film, and the hemispherical silicon dioxide is formed on the sapphire substrate, and the silicon dioxide material between the hemispheres is etched clean , exposing the sapphire substrate.

[0035] (4) Use No. 3 solution (H at 150 degrees Celsius) 2 SO 4 :H 2 o 2 =3:1) cleaning the sapphire substrate to prepare a sapphire pattern substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com