Photovoltaic array maximum power point tracking servo system and control method

A maximum power point, photovoltaic array technology, applied in photovoltaic modules, photovoltaic power generation, photovoltaic power stations, etc., can solve the problems of cumulative error, slow system action, poor reliability, etc., to increase the maximum output power, increase the received radiant energy, and eliminate the The effect of accumulating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

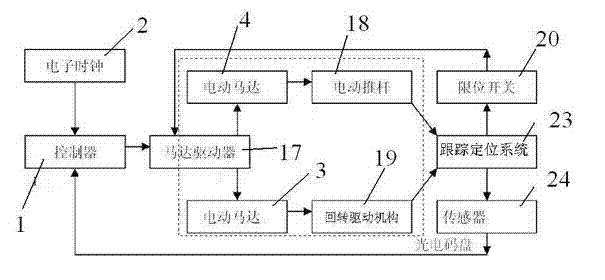

[0033] figure 1 It is a structural block diagram of the photovoltaic array maximum power point tracking servo system of the present invention.

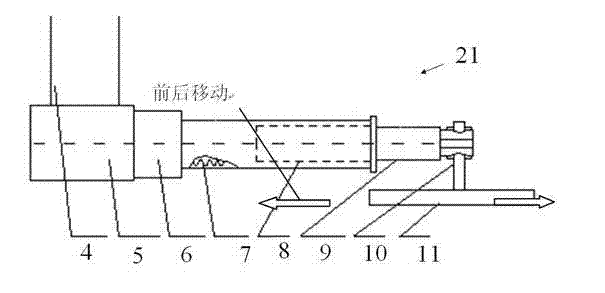

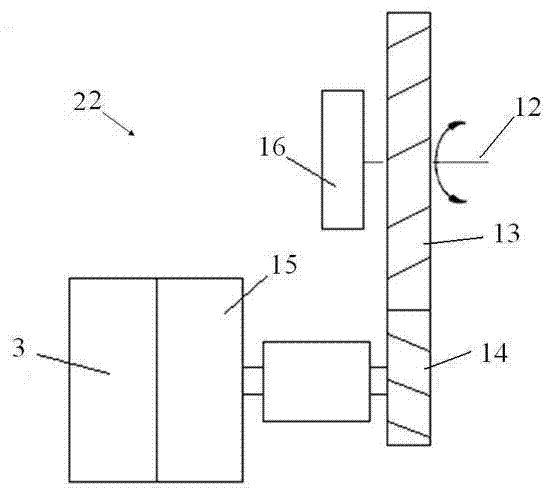

[0034] As shown in the figure, the photovoltaic array maximum power point tracking servo system disclosed by the present invention includes a clock circuit connected to a single-chip microcomputer control system, a two-axis mechanical tracking positioning system 23, and a photoelectric detection device, wherein the two-axis mechanical tracking The positioning system 23 includes a first tracking part 21 and a second tracking part 22 connected to the battery board support 16, the battery board and the photoelectric detection device are arranged on the battery board support 16, and the single-chip control system (for example, PLC or MCU controller 1 ) to respectively control and drive the first tracking component 21 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com