Mortar and debris collection device and system

a collection device and a technology for debris, applied in the direction of foundation engineering, building components, pillars, etc., can solve the problems of inability to collect debris, and no special fixation means for emplacement of the collection device is required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

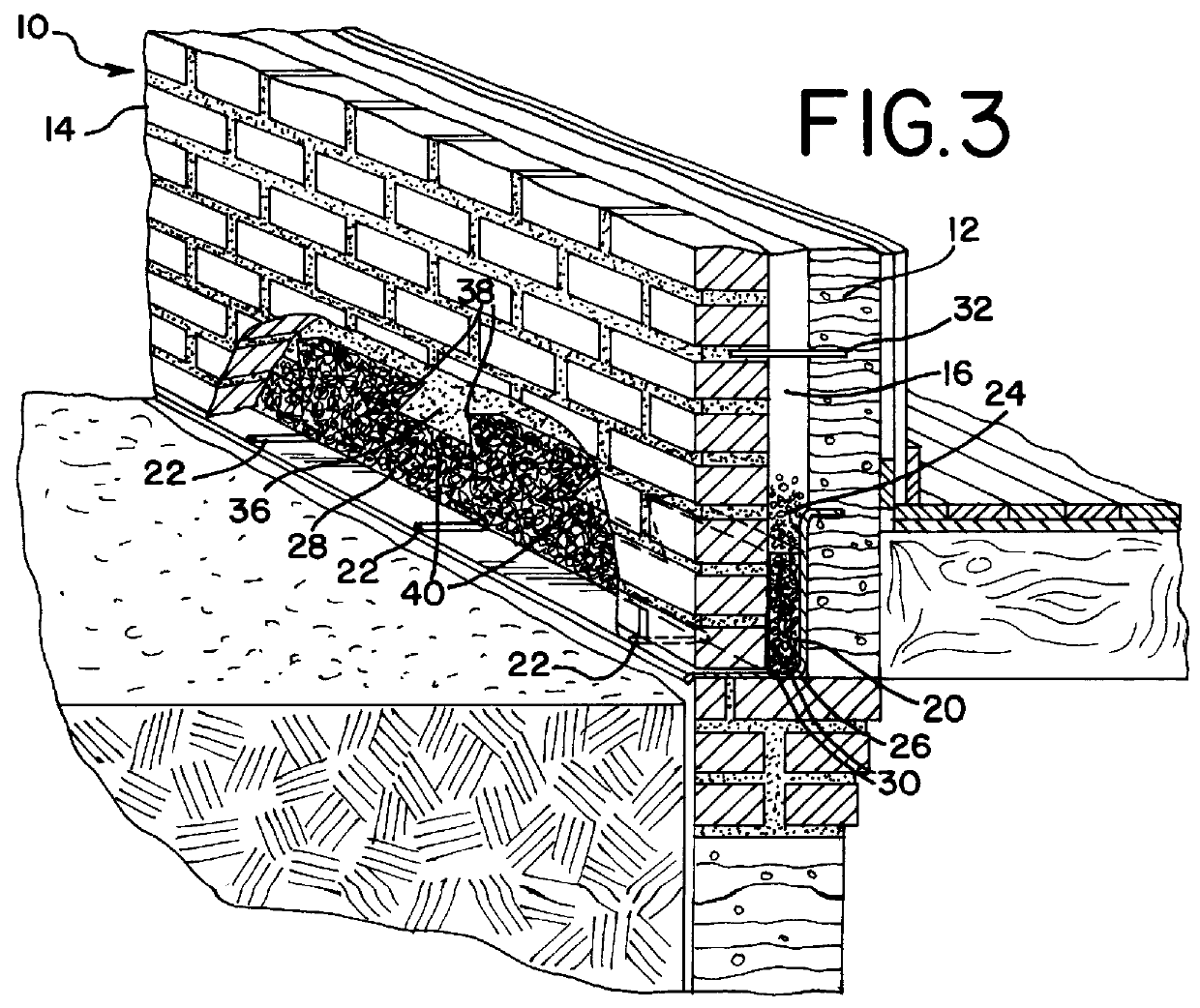

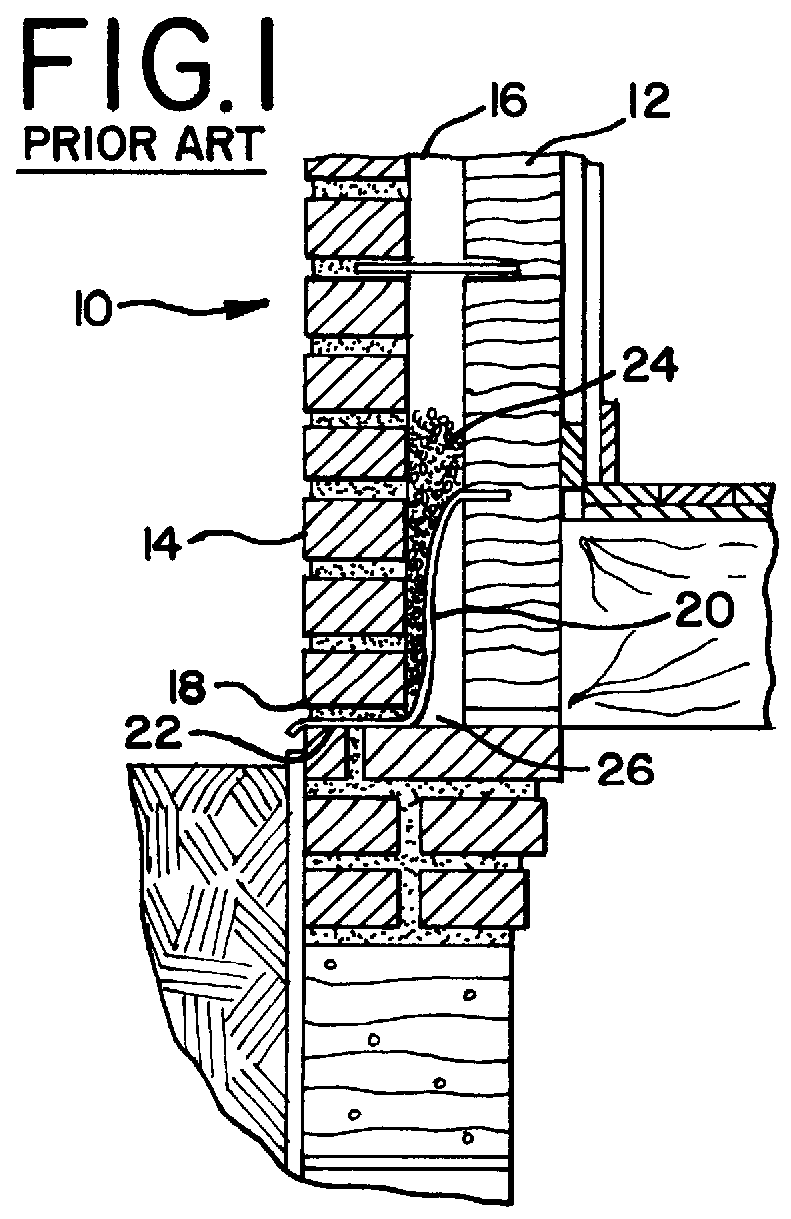

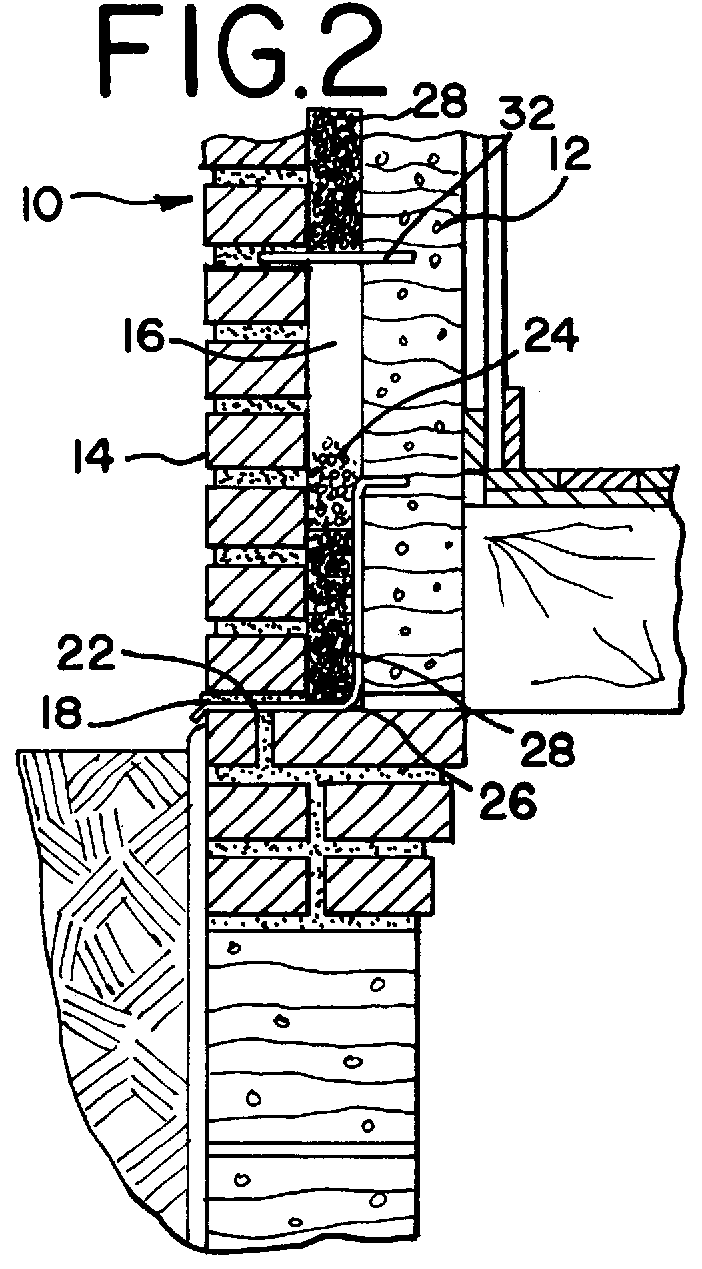

Brick masonry cavity walls 10, as shown in FIGS. 1, 2 and 3, consist of two wythes of masonry separated by an air space. The interior masonry wythe (the inner wall) 12 may be brick, hollow brick, structural clay tile, wood or hollow or solid concrete masonry units, for example. The exterior masonry wythe 14 (the outer wall) is brick. The cavity 16 between the two wythes may be either insulated or left open as air space. The cavity has a typical width of about 2 to about 4 1 / 2 inches, but could be smaller, although non-standard.

A common problem associated with a cavity wall construction is how to allow moisture, as from seepage or condensation, to pass from the cavity to outside the wall. Weep holes 18 creating an unobstructed opening passing from the cavity to the outside of the wall are provided to this end. Generally, the weep holes 18 will be placed approximately two feet apart at the base of the outer wall 14. Moisture collecting in the cavity is intended to run down the cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com