High-toughness die-casting aluminum alloy for new energy automobile and preparation method of high-toughness die-casting aluminum alloy

A technology for new energy vehicles and cast aluminum alloys, applied in the field of aluminum alloys, can solve the problems of inability to meet the performance requirements of high elongation, performance degradation, etc., achieve high crystal texture, and improve the effect of material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

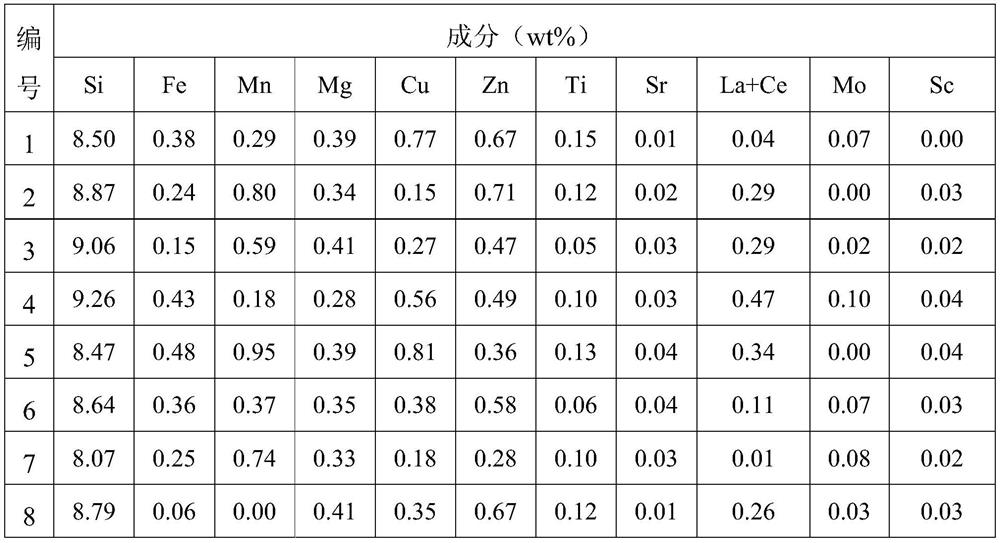

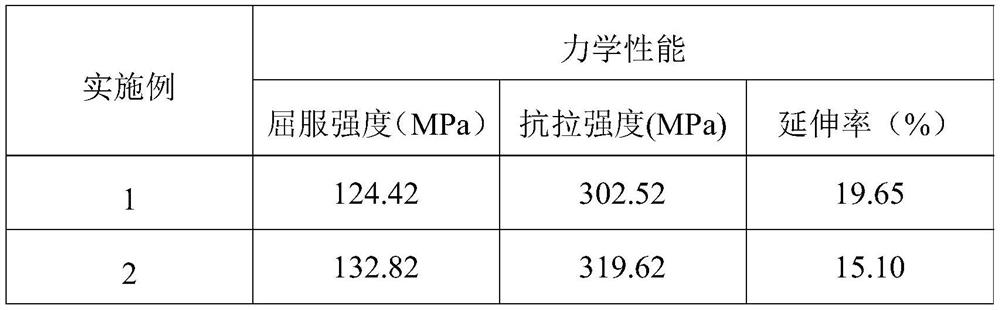

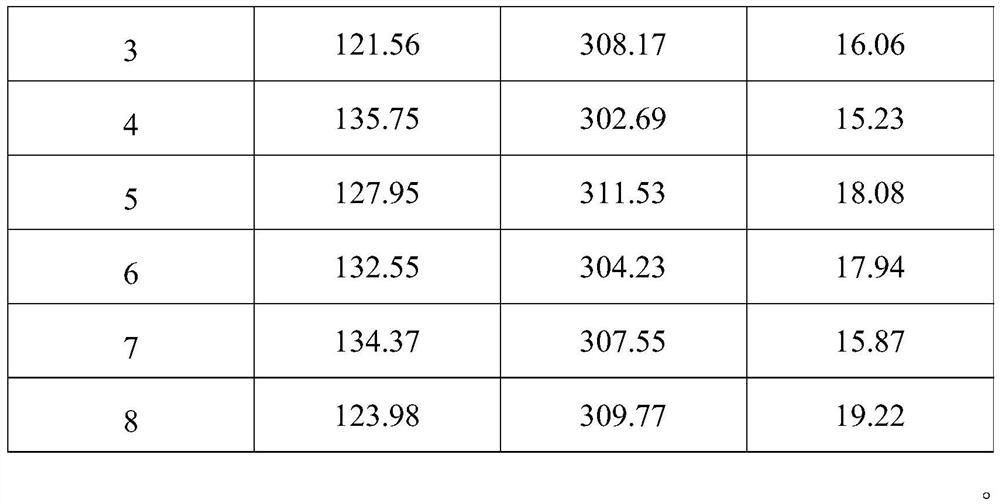

[0030] A high-strength and tough die-casting aluminum alloy for a new energy vehicle. In each embodiment, the alloy includes the components in mass percentages described in Table 1 below, and the balance is aluminum and unavoidable impurities.

[0031] The alloy material includes Si: 8wt%-10wt%; Fe: 0.05-0.5wt%; Mn<1.0wt%; Mg: 0.1-0.5wt%; Cu: 0.1-1.0wt%; Zn<1.0wt%; Ti: 0.05-0.2wt%; Sr: 0.005-0.05wt%; La+Ce<0.5wt%; Mo<0.1wt%; Sc<0.05wt%; The balance is Al.

[0032] Table 1 is the table of each element content in the aluminum alloy of embodiment 1-8

[0033]

[0034] The preparation method of the aluminum alloy described in the above-mentioned embodiments comprises the following steps:

[0035] 1) Calculate the mass of the required master alloy, weigh the commercially available Al-Ti-C-B, Al-20La+Ce, Al-20Mo and Al-3Sc master alloys, crush the smelted master alloys into blocks of appropriate size, Put it into a special quartz tube with a small hole in the bottom. Fix the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com