2.0 GPa-grade ultrahigh-yield-strength plastic CoCrNi-based medium-entropy alloy and preparation method thereof

A yield strength and entropy alloy technology, which is applied in the field of high-performance alloy material preparation, can solve problems such as the limitation of strength improvement, and achieve the effect of yield strength improvement and strong solid solution strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

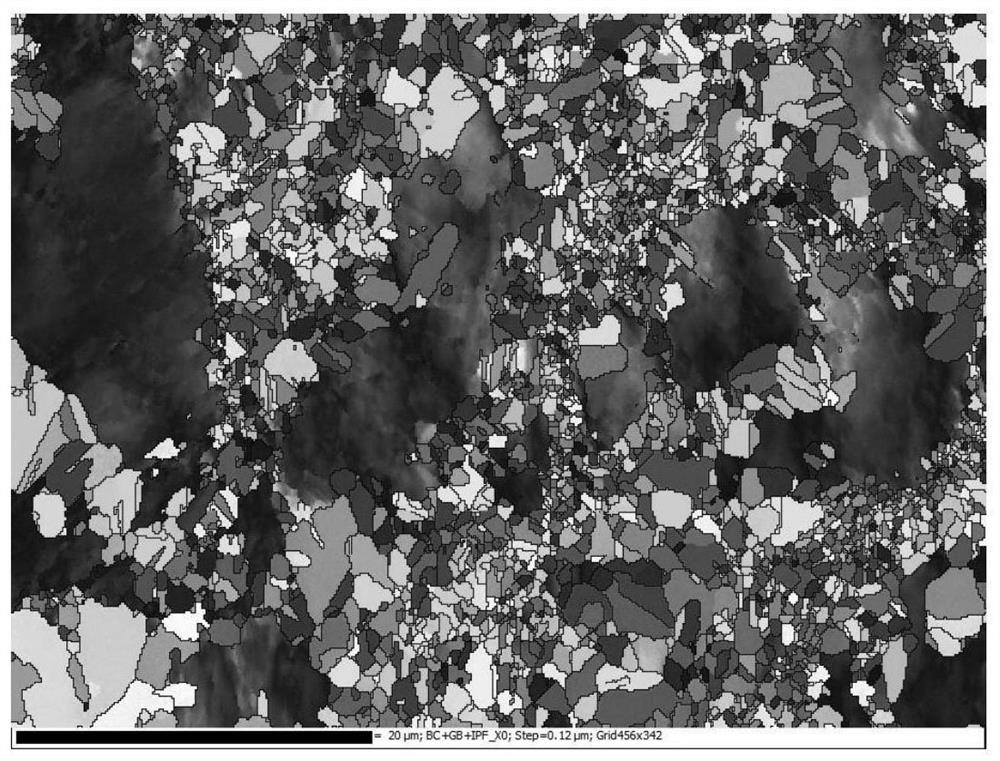

Image

Examples

Embodiment 1

[0026] (1) The preparation composition is (Co 40 Ni 30 Cr 20 al 5 Ti 5 ) 0.995 Mo 0.5 (at.%) alloy, wherein the subscript of each element is the atomic percentage of the element, which is melted and cast into a 5Kg ingot by a vacuum induction furnace;

[0027] (2) performing a homogenization treatment on the ingot at 1200°C / 12h and quenching to room temperature to form a homogenization treatment casting;

[0028] (3) performing a solution heat treatment at 1200°C / 2h on the homogenized casting and quenching to room temperature to obtain a single-phase alloy casting with a face-centered cubic structure (FCC);

[0029] (4) Carrying out cold deformation (cold rolling or swaging at room temperature) with a deformation amount of 80% to the alloy casting after solution heat treatment;

[0030] (5) Perform aging heat treatment at 650° C. / 24 h on the cold-deformed part to obtain the plastic CoCrNi-based medium-entropy alloy (sheet or rod) with ultra-high yield strength.

[0031...

Embodiment 2

[0034] (1) The preparation is Co 43 Ni 30 Cr 15 al 6 Ti 6 (at.%) alloy, melted and cast into 5Kg ingot by vacuum induction furnace;

[0035] (2) performing a homogenization treatment on the ingot at 1000°C / 20h and quenching to room temperature to form a homogenization treatment casting;

[0036] (3) performing a solution heat treatment at 1200°C / 3h on the homogenized casting and quenching to room temperature to obtain a single-phase alloy casting with a face-centered cubic structure (FCC);

[0037] (4) Carry out cold deformation (cold rolling or swaging at room temperature) with a deformation amount of 75% to the alloy casting after solution heat treatment;

[0038] (5) Perform aging heat treatment at 650° C. / 28 h on the cold-deformed part to obtain the plastic CoCrNi-based medium-entropy alloy (sheet or rod) with ultra-high yield strength.

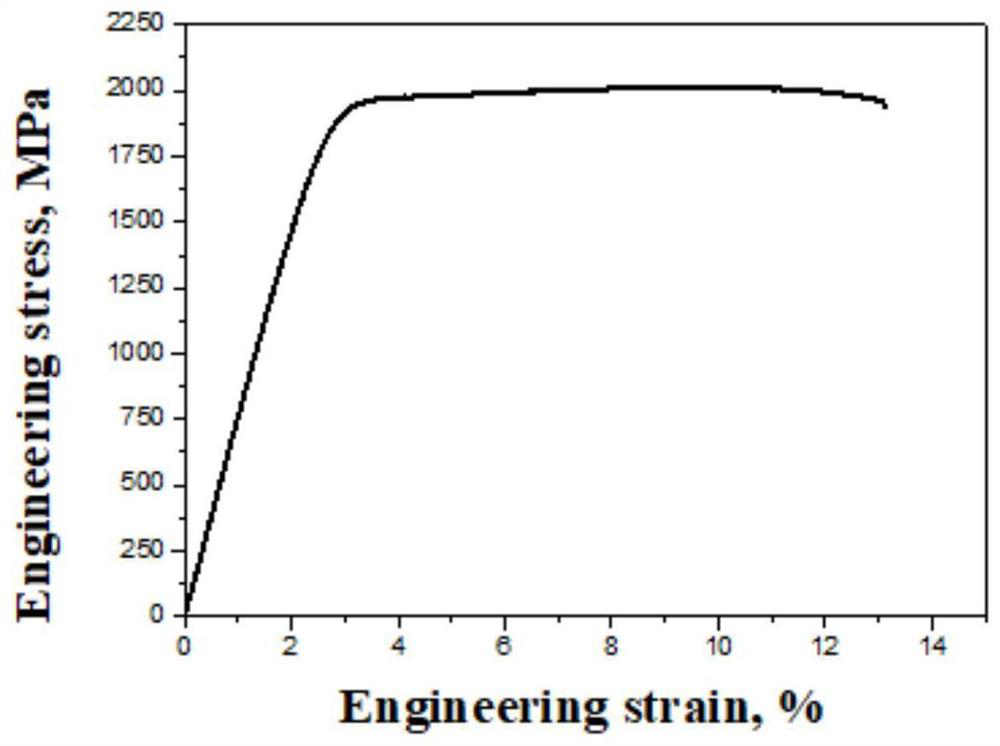

[0039] to 10 -3 the s -1 The obtained alloy sample is stretched at a certain tensile rate, and at room temperature, the tensile pl...

Embodiment 3

[0041] (1) The preparation composition is (Co 40 Ni 30 Cr 20 al 5 Ti 5 ) 0.985 Mo 1.5 (at.%) alloy, melted and cast into 5Kg ingot by vacuum induction furnace;

[0042] (2) performing a homogenization treatment on the ingot at 1100°C / 24h and quenching to room temperature to form a homogenization treatment casting;

[0043] (3) performing a solution heat treatment at 1200°C / 4h on the homogenized casting and quenching to room temperature to obtain a single-phase alloy casting with a face centered cubic structure (FCC);

[0044] (4) Carry out cold deformation (cold rolling or swaging at room temperature) with a deformation amount of 75% to the alloy casting after solution heat treatment;

[0045] (5) Perform aging heat treatment at 700° C. / 12 h on the cold-deformed part to obtain the plastic CoCrNi-based medium-entropy alloy (sheet or rod) with ultra-high yield strength.

[0046] to 10 -3 the s -1 The obtained alloy sample was stretched at a certain tensile rate. At roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com