Precipitation strengthening type medium-entropy alloy suitable for laser additive manufacturing and preparation method of precipitation strengthening type medium-entropy alloy

A precipitation strengthening and laser additive technology, applied in additive manufacturing, additive processing, etc., can solve the problems of cracking, high thermal residual stress, liquefaction cracking strain aging, etc., and achieve the effect of excellent comprehensive mechanical properties and excellent strengthening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention provides a preparation method of the above-mentioned precipitation-enhanced medium-entropy alloy by laser selective melting and forming technology, comprising the following steps:

[0046] 1. Preparation and pretreatment of medium entropy alloy powder

[0047] Proportioning is carried out according to the mole percentage of each element in the nominal chemical composition of the medium-entropy alloy, and the pre-alloyed spherical powder of the medium-entropy alloy is prepared by the vacuum atomization method, and the pre-alloyed spherical powder is sieved, and the particle size of the selected powder is 15- 53 μm. The oxygen content and nitrogen content are less than 300ppm, the preferred oxygen content is 131ppm, and the nitrogen content is 53ppm. Before laser selective melting, the pre-alloyed spherical powder is dried at 80°C for 4 hours to remove the moisture in the powder, and then placed in the powder feeding cylinder of the laser selective ...

Embodiment 1

[0062] A precipitation-enhanced medium-entropy alloy suitable for laser additive manufacturing, the chemical formula of which is Ni 35 co 35 Cr 25 Ti 3 Al 2 ; Wherein, the ratio of each element is mole percent. The selected medium entropy alloy is a gas-atomized pre-alloyed spherical powder with a purity greater than 99.9%.

[0063] In Example 1, the forming process of the medium entropy alloy prepared by laser selective melting technology is as follows:

[0064] 1. Preparation and pretreatment of medium entropy alloy powder

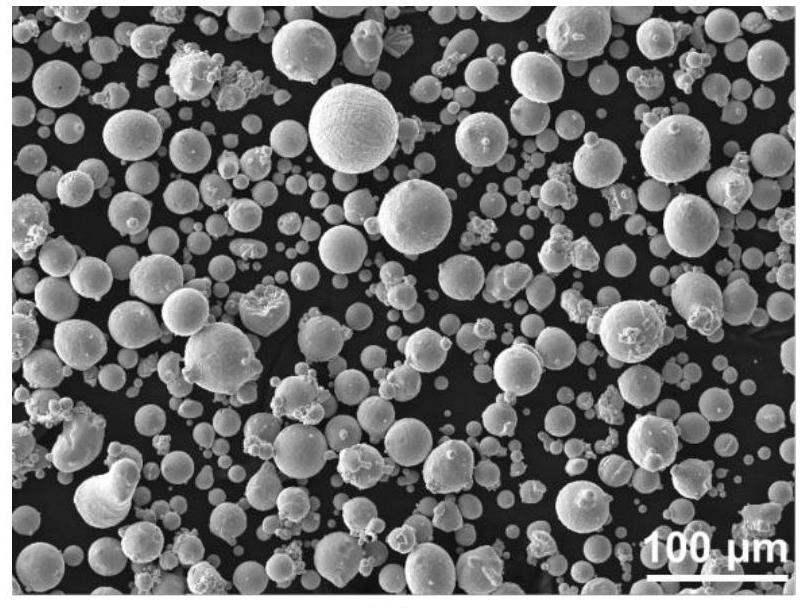

[0065] According to the molar ratio of each element in the nominal chemical composition of the above-mentioned medium-entropy alloy, the medium-entropy alloy pre-alloyed spherical powder is prepared by vacuum atomization method, and the pre-alloyed powder is sieved, and the particle size of the selected powder is 15- 53μm, its typical shape is as figure 1 shown. The oxygen content was 131 ppm and the nitrogen content was 53 ppm. Before laser selec...

Embodiment 2

[0082] A precipitation-enhanced medium-entropy alloy suitable for laser additive manufacturing, the chemical formula of which is Ni 35 co 35 Cr 25 Ti 3 Al 2 ; Wherein, the ratio of each element is mole percent. The selected medium entropy alloy is a gas-atomized pre-alloyed spherical powder with a purity greater than 99.9%.

[0083] Present embodiment 2 adopts laser three-dimensional forming technology to prepare medium entropy alloy forming process as follows:

[0084] 1. Preparation and pretreatment of medium entropy alloy powder

[0085] According to the molar ratio of each element in the nominal chemical composition of the medium-entropy alloy, the medium-entropy alloy pre-alloyed spherical powder is prepared by vacuum atomization method, and the pre-alloyed spherical powder is sieved, and the particle size of the powder is 45 -150μm, its typical shape is as Figure 8 shown. The oxygen content was 131 ppm and the nitrogen content was 53 ppm. Before the laser three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com