Si-containing high-strength low-modulus Beta-type titanium alloy and preparation method and application thereof

A titanium alloy, low-mold technology, used in prosthesis, tissue regeneration, medical science, etc., can solve the problems of weakened performance, poor plasticity, high brittleness of hypereutectoid steel, and achieve the effect of improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Alloy composition design: design titanium alloy composition as Ti 60at.%, Nb 20at.%, Zr10at.%, Ta5at.%, Si5at.%. The alloy is prepared from sponge titanium, sponge zirconium, tantalum-niobium master alloy and silicon.

[0034] (2) Casting: The casting process is vacuum consumable arc melting. The prepared raw materials are pressed into electrodes, and the size of the electrodes is controlled to be 50-70mm smaller than the crucible; the gap between the electrodes and the molten pool is controlled between 60-80mm; the melting speed is 20kg / min; ingot.

[0035] (3) Plastic deformation at high temperature: the ingot obtained by casting is cut into a cuboid sample of 15×25×80 mm. Choose Ti-6Al-4V as the sheath material, assemble the sheath with the sample, heat to 900°C, and keep it warm for 30min. Multi-pass hot rolling. Finally, a sample with a rolling ratio of 80% was obtained and water quenched to room temperature.

[0036](4) Recovery and recrystallization: rem...

Embodiment 2

[0042] (1) Alloy composition: design titanium alloy composition as Ti 70at.%, Nb 10at.%, Zr10at.%, Ta6at.%, Si 4at.%. The above-mentioned components of the alloy are prepared with sponge titanium, sponge zirconium, tantalum-niobium master alloy and silicon as raw materials.

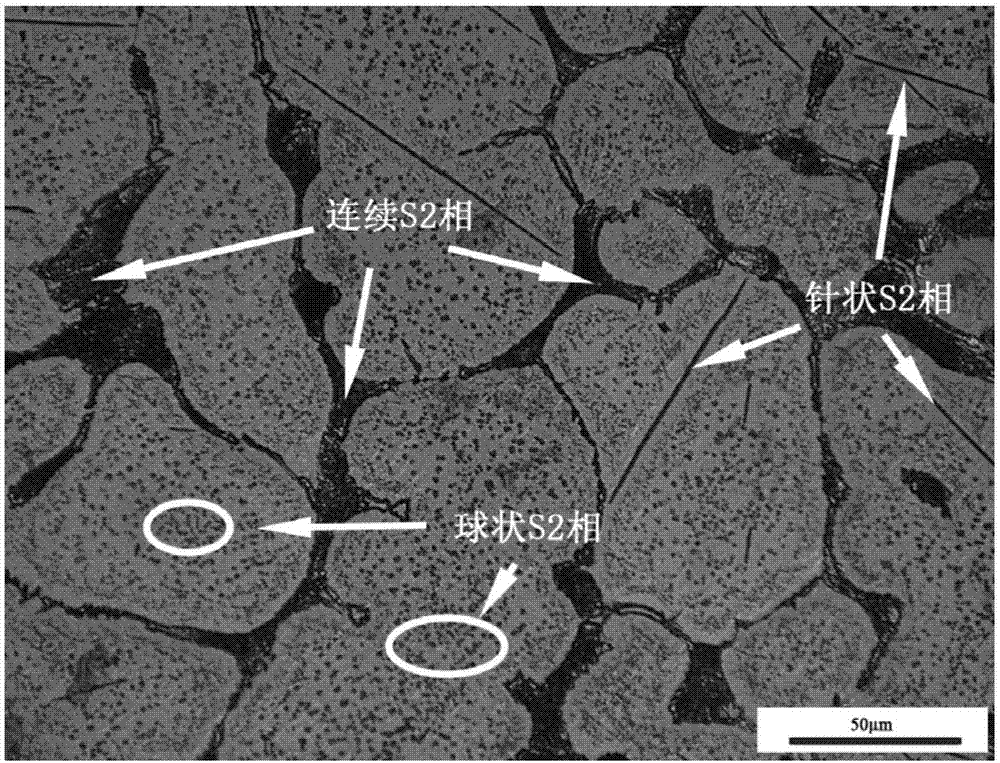

[0043] (2) Casting: The casting process is vacuum consumable arc (VAR) melting. The prepared raw materials are pressed into electrodes, and the electrode size is controlled to be 50-70mm smaller than the crucible; the gap between the electrode and the molten pool is controlled to be between 60-80mm; the melting speed is 20kg / min. Remelt twice to get ingots. The dendritic β-titanium matrix with the as-cast microstructure of 50-300 μm is dispersed with spherical S2 phases with a size of about 1-3 μm and acicular S2 phases with a length of about 50-100 μm, and the grain boundaries are continuous. S2 phase.

[0044] (3) Plastic deformation at high temperature: Cut the ingot obtained by casting into a cube ...

Embodiment 3

[0048] (1) Alloy composition: design titanium alloy composition as Ti 65at.%, Nb 15at.%, Zr10at.%, Ta7at.%, Si 3at.%. The above-mentioned components of the alloy are prepared with sponge titanium, sponge zirconium, tantalum-niobium master alloy and silicon as raw materials.

[0049] (2) Casting: The casting process is vacuum consumable arc (VAR) melting. The prepared raw materials are pressed into electrodes, and the electrode size is controlled to be 50-70mm smaller than the crucible; the gap between the electrode and the molten pool is controlled to be between 60-80mm; the melting speed is 20kg / min. Remelt twice to get ingots. Spherical S2 phases with a size of about 1-3 μm and acicular S2 phases with a length of about 50-100 μm are dispersed on the dendritic β-titanium matrix with a microstructure of 50-300 μm in the as-cast state, and the grain boundaries are continuous. S2 phase.

[0050] (3) Plastic deformation at high temperature: the ingot obtained by casting is cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com