Preparation method for dual model-structure graphene-reinforced aluminum matrix composite

A technology for strengthening aluminum-based and composite materials, applied in graphene, chemical instruments and methods, temperature control, etc., can solve the problems of strength-toughness inversion, easy agglomeration of graphene, etc., achieve excellent strength and toughness, and less interface reaction , the effect of shortening the time of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

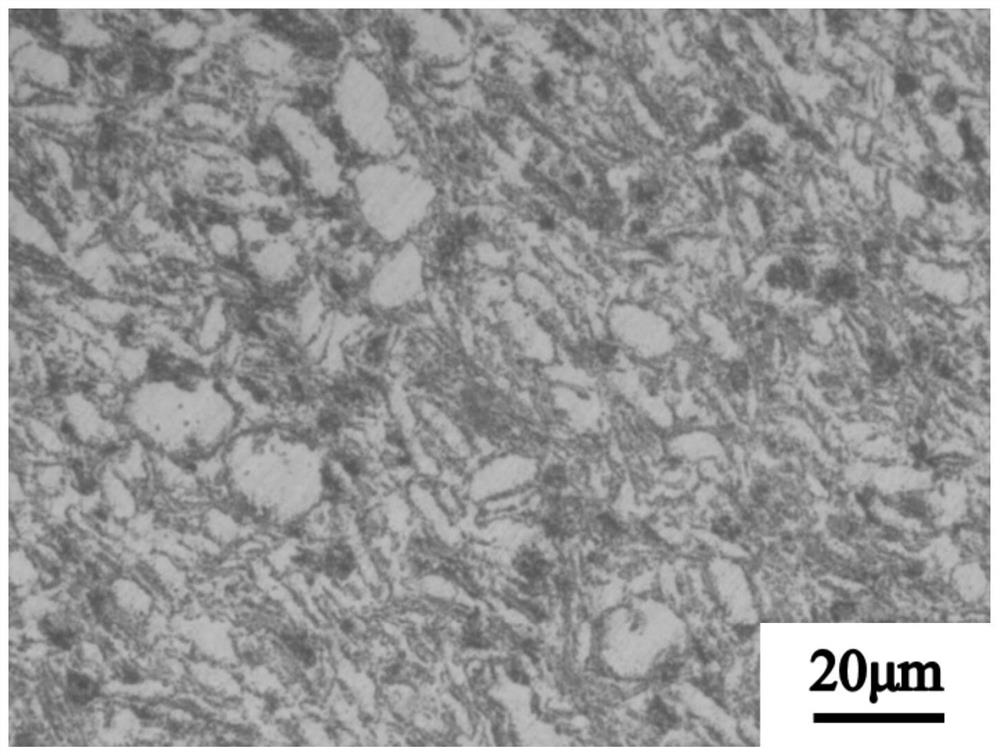

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: the preparation method of the dual-mode structure graphene reinforced aluminum-based composite material of the present embodiment is carried out according to the following steps:

[0025] 1. Weighing

[0026] Weighing 1.2% to 1.8% graphene oxide and 98.2% to 98.8% aluminum metal powder as raw materials by mass fraction;

[0027] 2. Preparation and dispersion of three-dimensional graphene

[0028] Add the graphene oxide weighed in step 1 into distilled water for ultrasonic dispersion to obtain a graphene oxide dispersion; add ascorbic acid solution to the graphene oxide dispersion under magnetic stirring conditions to obtain a graphene oxide colloid, and the graphene oxide colloid Carrying out vacuum freeze-drying to obtain a three-dimensional graphene skeleton; mixing the three-dimensional graphene skeleton with the aluminum metal powder weighed in step 1 and then ball milling to obtain a mixed powder;

[0029] 3. Preparation of double-mode st...

specific Embodiment approach 2

[0040] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the average sheet diameter of the graphene oxide described in step 1 is 2 μm to 5 μm, and the average thickness is 5 to 10 nm; the average particle size of the aluminum metal powder described in step 1 The diameter is 10-30 μm.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aluminum metal powder in step 1 is made of Al-Mg-Si alloy, Al-Cu-Mg alloy, Al-Cu-Mn-Mg alloy, Al-Mn-Si-Cu alloy, Al-Si-Mg-Be alloy; in the Al-Mg-Si alloy, Mg is 0.45-4.8%, Si is 4.5-6.5%, and Cu is 0.6% ~0.8%; Cu in Al-Cu-Mg alloy is 1.5~4.5%, Mg is 0.3~3.8%; Cu in Al-Cu-Mn-Mg alloy is 3.8~4.9%, Mn is 0.3~9%, Mg is 1.5-1.8%; in Al-Mn-Si-Cu alloy, Mn is 4.2-5.6%, Cu is 0.6-0.8%, Fe is 0.1-1.0%, Si is 7.0-12%, and Ti is 0.1-1.0%; Al In the -Si-Mg-Be alloy, Si is 4.5-8.0%, Mg is 0.4-1.5%, Ti is 0.15-0.25%, and Be is 0.15-0.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com