Preparation method of light titanium-rich Ti-Zr-Nb-Al series refractory high-entropy alloy-based composite material

A technology of ti-zr-nb-al and high-entropy alloys, which is applied in the field of preparation of new metal materials, can solve the problems of not being able to prepare large sizes, poor plasticity, and high density of refractory high-entropy alloys, so as to improve plasticity and grain size. Thinning, strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Embodiment 1: In this embodiment, a method for preparing a light-weight titanium-rich Ti-Zr-Nb-Al system refractory high-entropy alloy-based composite material is specifically carried out according to the following steps:

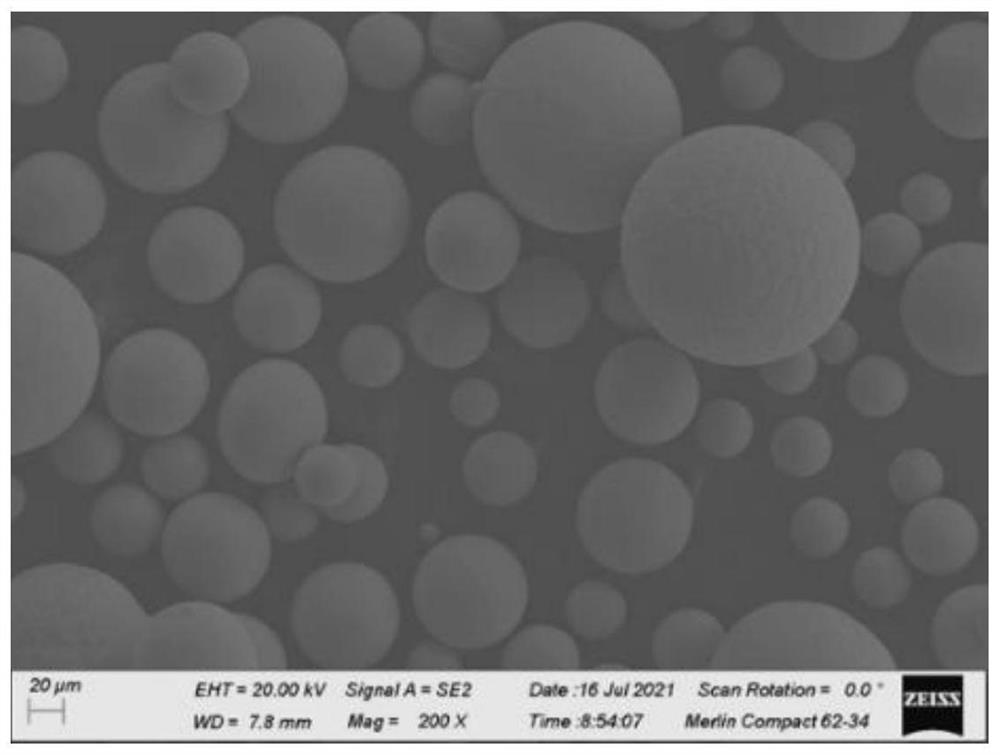

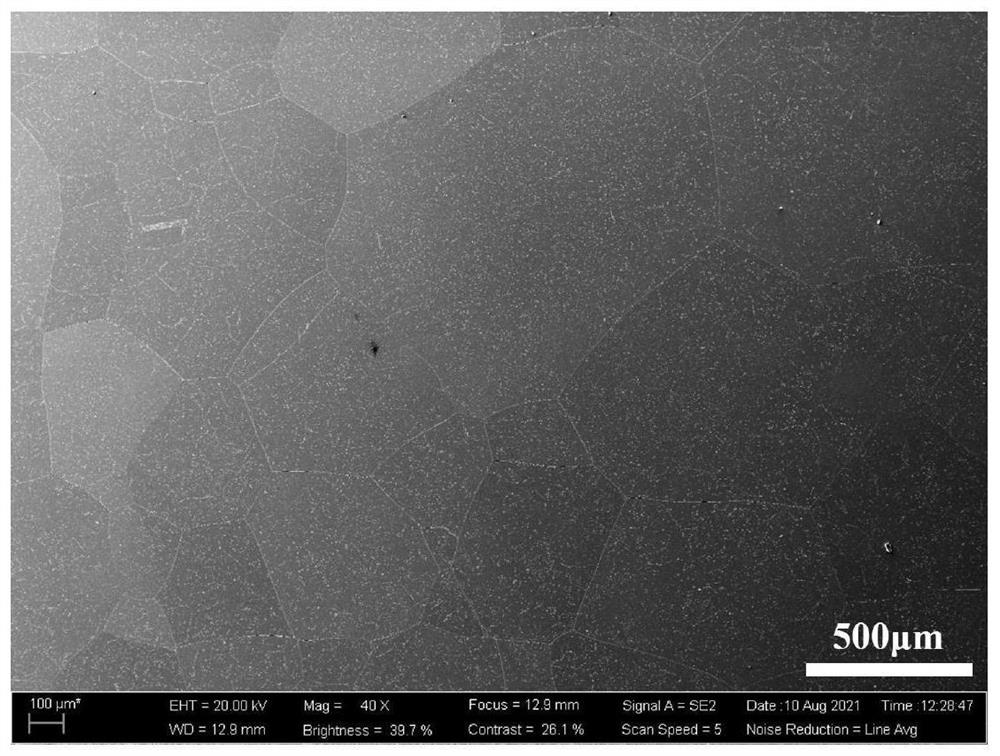

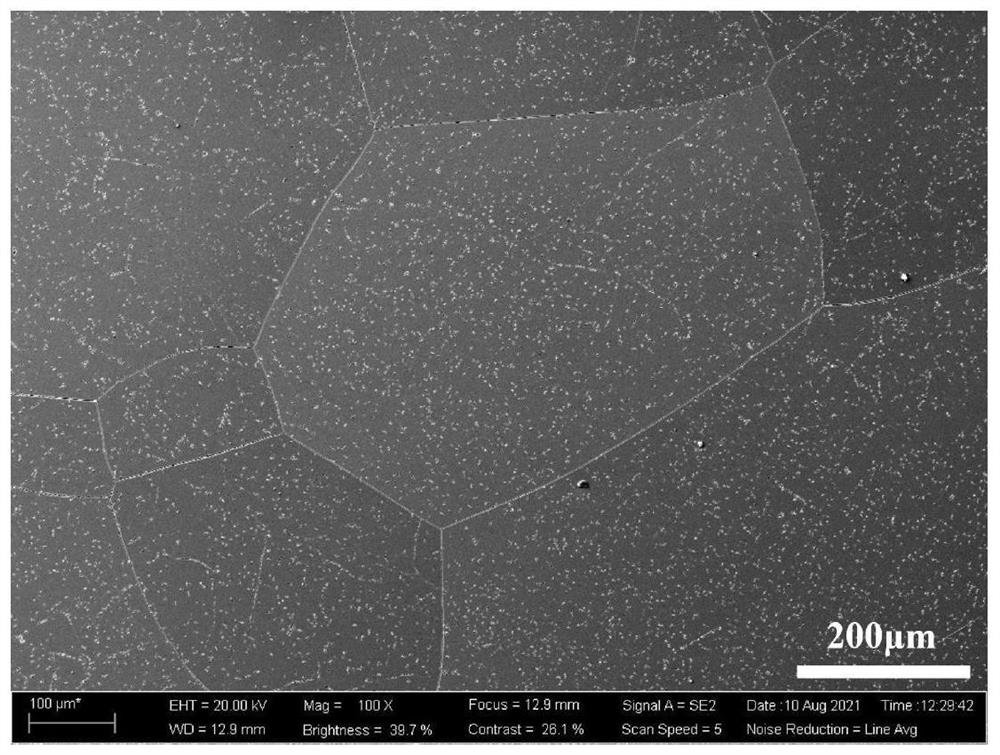

[0020] 1. The elements and atomic ratios contained in high-entropy alloys are: Ti:Zr:Nb:Al=a:b:c:d, and the chemical composition of each element is 25≤a≤40, 25≤b≤35, 25≤c ≤35, 5≤d, a+b+c+d=100; use Ti, Zr, Nb, Al raw materials with a purity of 99.5% or more; weigh the raw materials according to the above ratio, mix and smelt the raw materials into metal ingots, and then pass High energy density plasma rotating electrode atomization technology is used to make powder and obtain matrix powder;

[0021] 2. Weigh the added reinforcement powder; the added reinforcement powder is B powder, TiB 2 Powder, NbB 2 Powder or ZrB 2 pink;

[0022] 3. After mixing the matrix powder and the external reinforcement powder, perform low-energy ball milling in a high-...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the diameter of the reinforcement powder added in Step 2 is 1-5 μm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the added reinforcement powder in step 2 is 1% to 5% of the mass of the matrix powder. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com