Carbon-based composite film and preparation method thereof

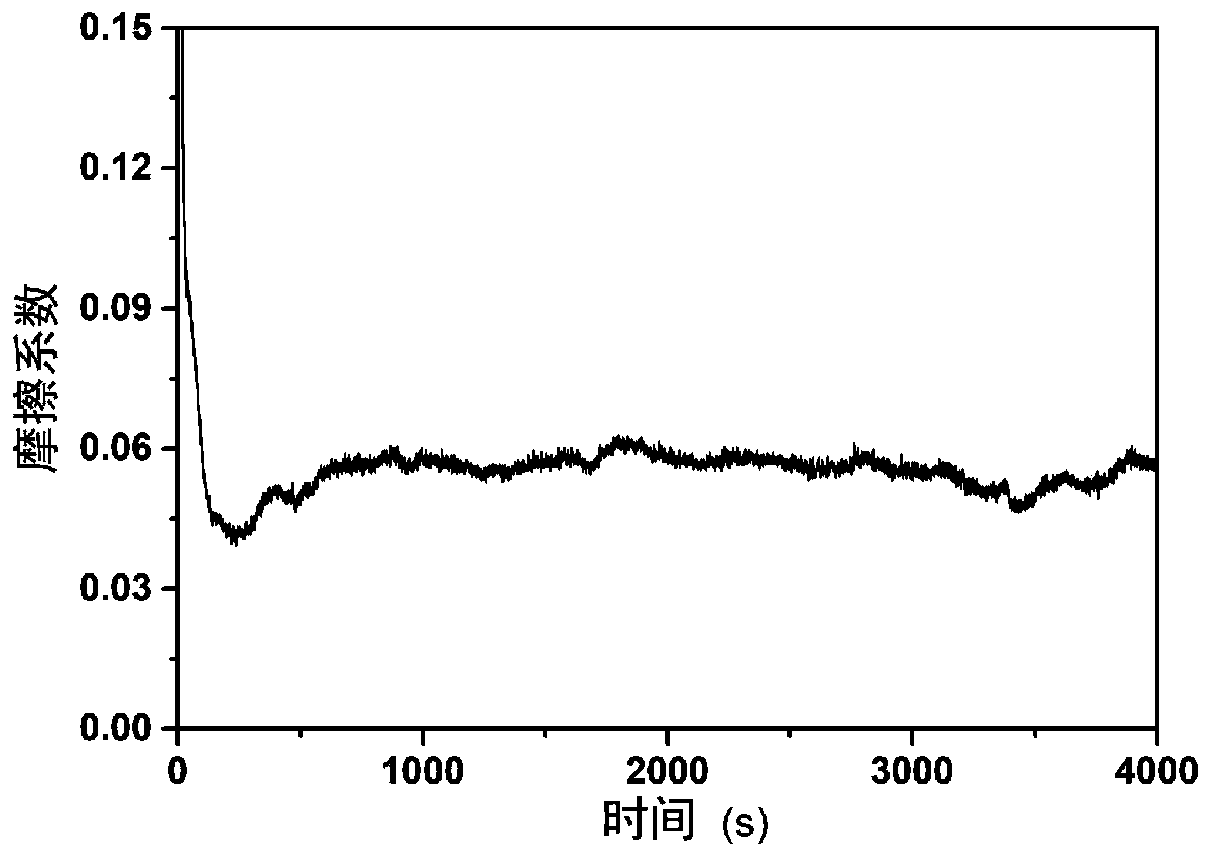

A composite film and carbon-based technology, applied in the field of surface engineering, can solve the problems of increasing the friction coefficient of the film, abrasive wear, and deterioration of tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing a carbon-based composite film, comprising the following steps:

[0028] Activating the metal substrate to obtain an activated metal substrate;

[0029] Using metal targets, carbon targets and metal carbide targets as sputtering targets, performing closed-field unbalanced magnetron sputtering on the activated metal substrate to form a gradient transition layer;

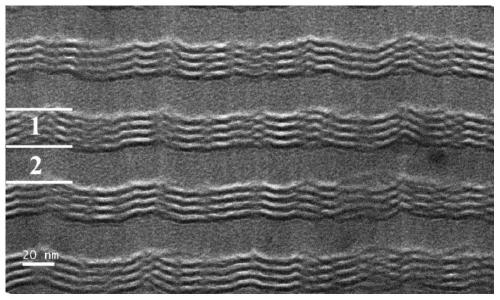

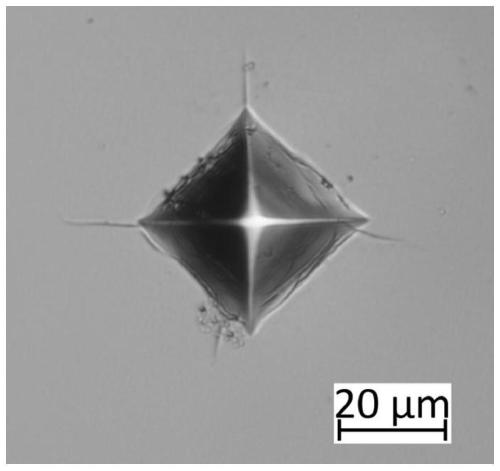

[0030] Using a carbon target and a metal carbide target as a sputtering target, performing magnetron deposition on the surface of the gradient transition layer to form a nano-multilayer-nano-composite double structure to obtain the carbon-based composite film;

[0031] When the rotational speed of the sample turret of the magnetron deposition is 0.5-5 rpm, a nano-multilayer structure is formed; when the rotational speed of the sample turret of the magnetron deposition is 5-8 rpm, a nanocomposite structure is formed;

[0032] The metal carbide targets are all Cr 3 C...

Embodiment 1

[0054] Concrete preparation method comprises the following steps:

[0055] (1) Presetting of the sputtering plane target: ensure that the metal substrate fixed on the sample turret is kept parallel to the surface of the sputtering target, and the distance between the two is kept at 10 cm, and the C target and the WC target are placed opposite to each other.

[0056] (2) Substrate polishing and cleaning: Grind and polish the surface of the 316L stainless steel substrate step by step to a surface roughness Ra≤0.2 μm, and then ultrasonically clean it with acetone and absolute ethanol for 20 minutes at an ultrasonic power of 600W and a temperature of 25°C, respectively. After drying with nitrogen gas, fix it on the sample turntable.

[0057] (3) Activation of the substrate surface: when the vacuum degree of the closed-field unbalanced magnetron sputtering deposition chamber reaches 5×10 -4 Pa, pass high-purity argon gas, the air pressure is controlled at 2.0Pa, and the surface of...

Embodiment 2

[0066] Concrete preparation method comprises the following steps:

[0067] (1) Presetting of the sputtering plane target: ensure that the metal substrate fixed on the sample turret is kept parallel to the surface of the sputtering target, and the distance between the two is kept at 10 cm, and the C target and the WC target are placed opposite to each other.

[0068] (2) Substrate polishing and cleaning: Grind and polish the surface of the 316L stainless steel substrate step by step to a surface roughness Ra≤0.2 μm, and then ultrasonically clean it with acetone and absolute ethanol for 20 minutes at an ultrasonic power of 600W and a temperature of 25°C, respectively. After drying with nitrogen gas, fix it on the sample turntable.

[0069] (3) Activation of the substrate surface: when the vacuum degree of the closed-field unbalanced magnetron sputtering deposition chamber reaches 5×10 -4 Pa, pass high-purity argon gas, the air pressure is controlled at 2.0Pa, and the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com