Method for improving room temperature plasticity of refractory high-entropy alloy

A high-entropy alloy and room temperature technology, which is applied in the field of smelting refractory high-entropy alloys to improve their room temperature plasticity, can solve the problems of limiting alloy cold-state manufacturability, low deformation limit, and poor room-temperature plasticity, so as to improve cold-state plastic deformation The effect of limit, room temperature compression plasticity improvement, and microstructure refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Preparation of High Room Temperature Plastic Refractory High Entropy Alloy (TiZrNbHf0.5Mo0.5)

[0019] Raw material preparation

[0020] The alloy raw materials used in this embodiment are Nb, Mo, Ti, Zr, Hf refractory metal elements with a purity above 99%. All materials are blocks, and the oxide skin on the surface of the material is removed by grinding with sandpaper or grinding wheel, and placed in industrial ethanol to clean with ultrasonic vibration, and then according to the atomic ratio of the constituent elements Nb:Mo:Ti:Zr:Hf=1:0.5:1 :1:0.5, accurate weighing.

[0021] alloy melting

[0022] The invention uses a vacuum non-consumable electric arc furnace to smelt the alloy. Put the proportioned and weighed raw materials in the water-cooled copper crucible according to the melting point of the elements from low to high, and vacuumize the furnace cavity to 6×10 -3 Pa, hydrogen and argon with a purity of 99.999% are introduced into the melting cham...

Embodiment 4

[0028] Embodiment 4 characterizes:

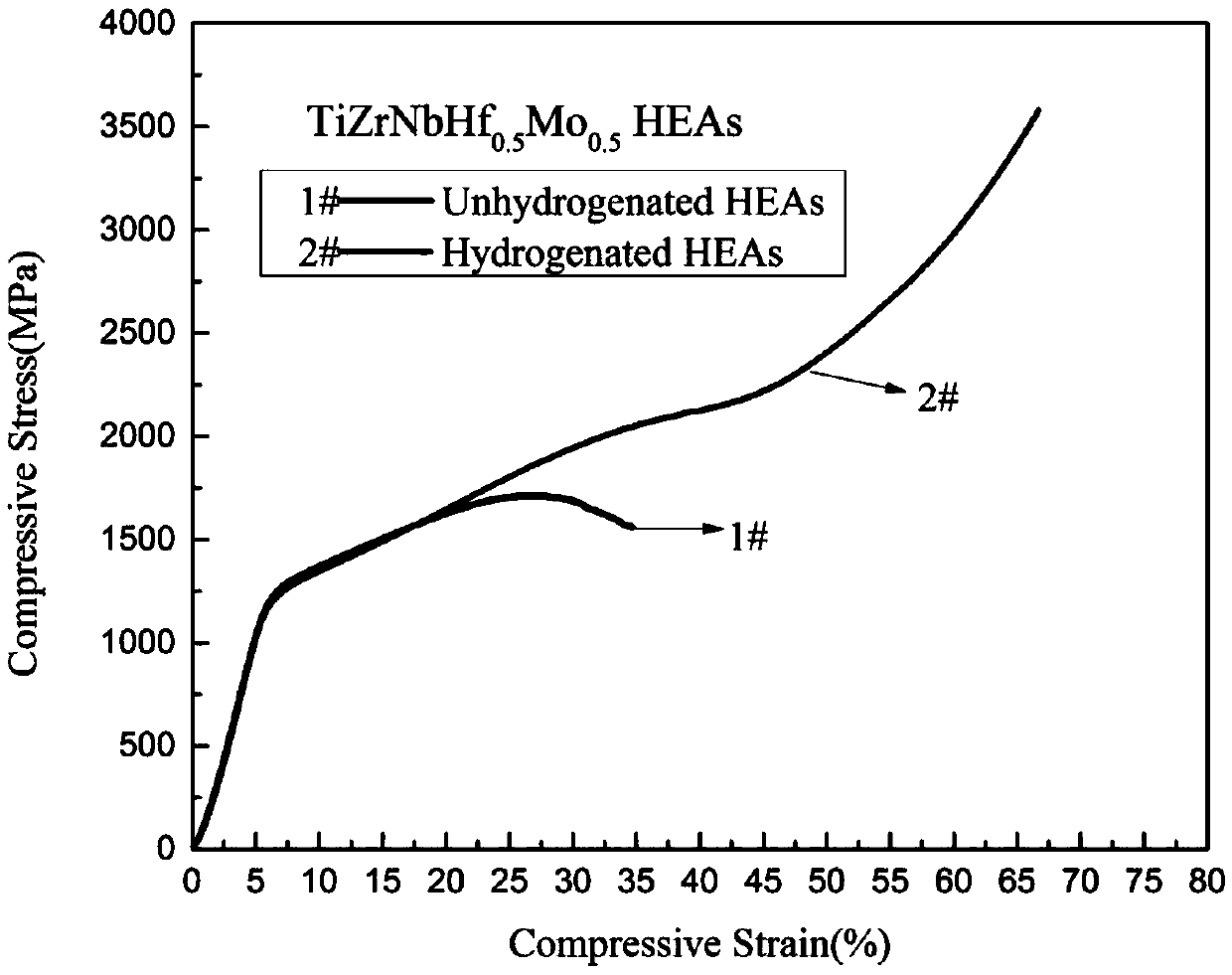

[0029] Evaluation of Compressibility of Alloys at Room Temperature by Liquid Hydrogen Substitution

[0030] (1) Compression test at room temperature

[0031] Adopt wire cutting to cut respectively on the middle part of the alloy button ingot prepared by smelting of comparative example 1 and embodiment 1 For the cylindrical sample, use sandpaper to polish the upper and lower end faces and side surfaces of the cylindrical sample. The room temperature compression performance test was carried out on the universal electronic testing machine Instron-5569, and the compression rate was 1×10 -3 the s -1 , the compressive stress-strain curve of the alloy obtained from the test is as follows figure 1 Shown (Unhydrogenated represents comparative example 1, and Hydrogenated represents embodiment 1). Compared with the alloy prepared under the condition of pure argon, it is found that the room temperature plasticity of the alloy TiZrNbHf0.5Mo0.5 pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com