Method for improving plasticity of bulk metal glass and structural component thereof

A technology for bulk metal and structural parts, which is applied in the field of improving the plasticity of bulk metal glass and its structural parts by gas-phase hydrogenation method, can solve the problems of difficult distribution, low yield strength, and high improvement, and achieves improved plasticity and high yield strength. The effect of reducing and not reducing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

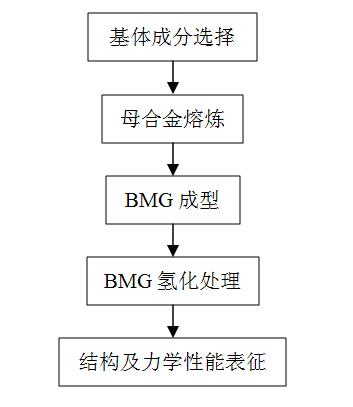

Method used

Image

Examples

Embodiment 1

[0026] Selection of matrix components: The purity of the raw materials used to prepare the master alloy ingot is 99.9% Cu, 99.99% Zr, 99.5% Al and 99.99% Ni, and the nominal composition of the alloy is Cu 45 Zr 46 al 7 Ni 2 (atomic percent).

[0027] Preparation of the master alloy: Under the condition of Ti inhalation and high-purity argon protection, the master alloy is melted by non-consumable arc melting.

[0028] Mechanically grind the surface of the metal raw material to remove the oxide skin on the surface, and mix the ingredients according to the designed composition ratio; weigh the precision

[0029] To within 0.001g, put the prepared material into the water-cooled copper crucible in the melting furnace according to the weight of about 60-80g per ingot

[0030] Inside, cover the furnace lid and evacuate to 5×10 -3 Below Pa; fill the furnace with high-purity argon with a pressure of 0.06MPa.

[0031] Before the master alloy ingot is melted, the Ti ingot use...

Embodiment 2

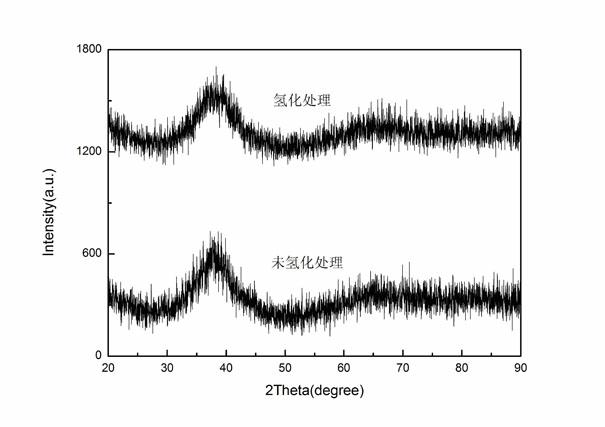

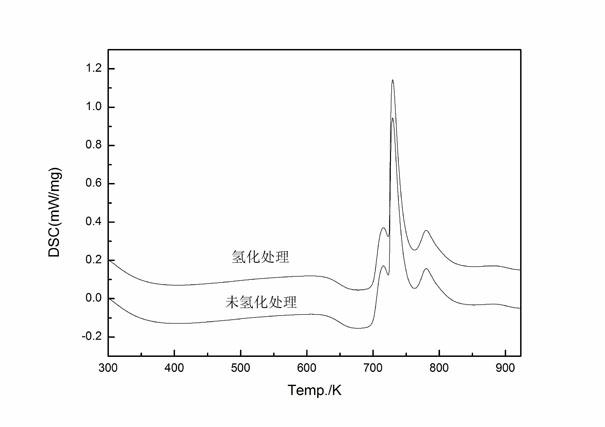

[0037] The matrix composition is selected as Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5(atomic percent). The preparation of the master alloy is the same as step 2 of Example 1, and the preparation of the sample is the same as step 3 of Example 1, except that the hydrogenation treatment temperature is 100° C., the hydrogen pressure is 5 MPa, and the hydrogenation time is 1.5 hours. The performance test is the same as step 5 of Example 1. The structure and thermal stability of the hydrogenated BMG do not change, the hydrogenated BMG has a plastic deformation of 3.5%, and the non-hydrogenated BMG has no plasticity.

Embodiment 3

[0039] The matrix composition is chosen as La 62 al 14 (Cu,Ni) 24 (atomic percent). The preparation of the master alloy is the same as step 2 of Example 1, and the preparation of the sample is the same as step 3 of Example 1, except that the hydrogenation treatment temperature is 80° C., the hydrogen pressure is 10 MPa, and the hydrogenation time is 0.5 hours. The performance test is the same as step 5 of Example 1. The structure and thermal stability of the hydrogenated BMG do not change, the hydrogenated BMG has a plastic deformation of 2.5%, and the unhydrogenated BMG has no plasticity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com