Polychloroethylene heat stabilizer having dioctyl tin maleate structure and preparation thereof

A technology of dioctyl tin acid and heat stabilizer is applied in the field of polyvinyl chloride heat stabilizer containing dioctyl tin maleate structure and its preparation, and achieves the effects of good dispersibility, improved heat stabilization efficiency and good compatibility

Active Publication Date: 2010-12-29

CHANGJI XINMINGTAI NEW MATERIAL TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the problems existing in the PVC heat stabilizer in the prior art, the present invention provides a polymer polyvinyl chloride heat stabilizer and a preparation method thereof, aiming at solving the following technical problems: increasing the compatibility between the heat stabilizer and PVC , so that the heat stabilizer can be uniformly dispersed in PVC, improve the heat stabilization performance; reduce the volatilization phenomenon of the heat stabilizer when used, and improve the utilization rate of the heat stabilizer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation Embodiment 1

preparation Embodiment 2

preparation Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Login to View More

Abstract

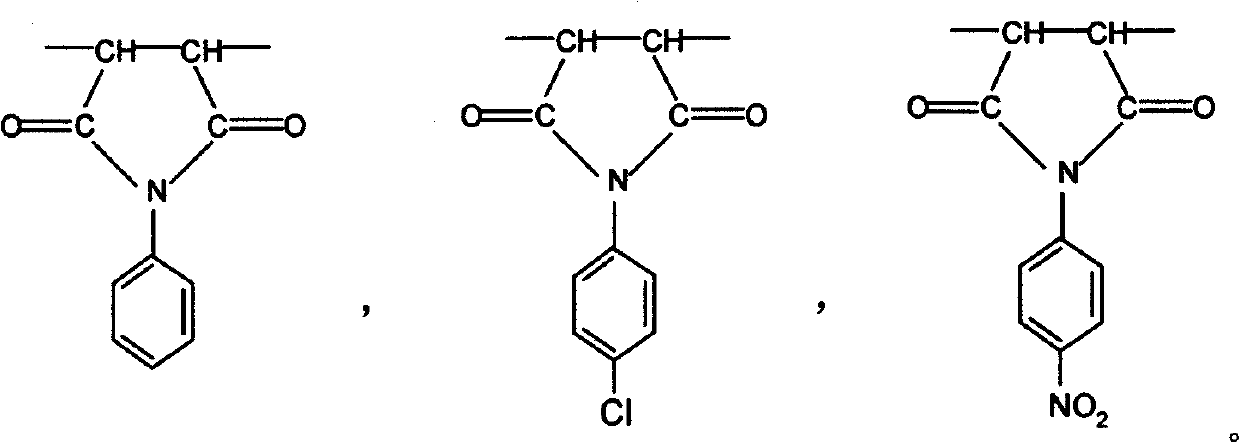

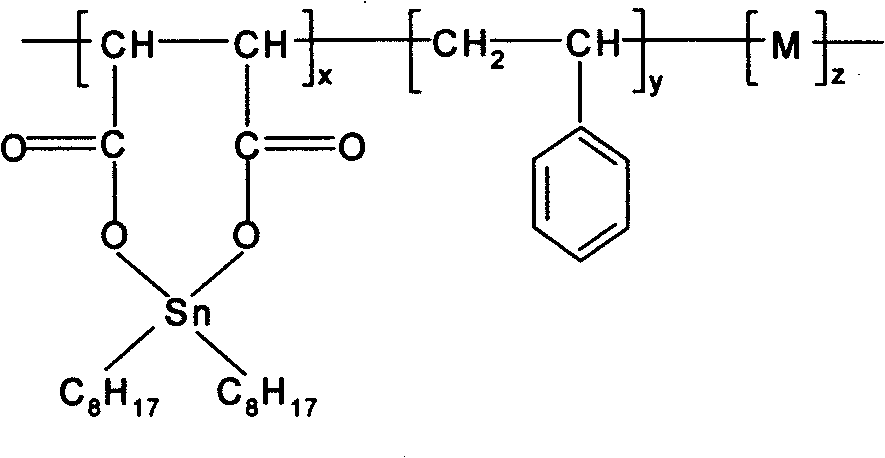

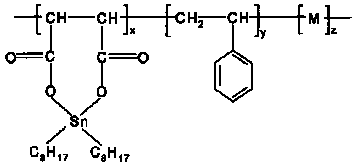

The invention relates to polyvinyl chloride thermal stabilizer containing dioctyltin maleate structure and a method for making the same. The polyvinyl chloride thermal stabilizer comprises the terpolymer as shown in the following structural formula, wherein x:y:z (molar ratio) is equal to (1-2):(3-15):(0.1-1); and M is N-phenyl maleimide, p-chlorophenyl maleimide and N-p-nitrophenyl maleimide. The method is as follows: nitrogen is injected into a reactor provided with a stirring reflux device; then, dioctyltin maleate, phenethylene and N-phenyl maleimide monomer are added in the reactor and are stirred till the mixture becomes a transparent solution; then, initiator is added to carry out nitrogen protection; polyreaction is carried out at a temperature of between 50 and 90 DEG C for 3 to 12 hours; finally, the reaction is stopped, and the reaction liquid is injected into methanol solvent so as to obtain polyvinyl chloride thermal stabilizer product after deposition. The polyvinyl chloride thermal stabilizer has the advantages of high thermostabilization efficiency, low cost, non toxicity and environmental protection.

Description

technical field The invention relates to a polyvinyl chloride heat stabilizer, in particular to a polyvinyl chloride heat stabilizer containing a dioctyltin maleate structure and a preparation method thereof. Background technique Polyvinyl chloride (PVC) is widely used in insulating materials, building materials and daily-use plastic products because of its low price and excellent performance. In recent years, my country's total demand for PVC is still showing a stable double-digit growth trend. However, due to structural defects in the PVC molecular chain, hydrogen chloride will be released when heated to 110°C, and the released hydrogen chloride will accelerate the decomposition of PVC. Therefore, PVC will be significantly degraded when the processing temperature is 160-200°C, causing product discoloration and product mechanical properties, etc. The decline will affect the service life. In order to prevent PVC from degrading during processing, heat stabilizers need to be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F212/08C08F230/04C08F222/40C08L27/06C08L43/00

Inventor 刘建平宋霞郑玉斌尚宏周

Owner CHANGJI XINMINGTAI NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com