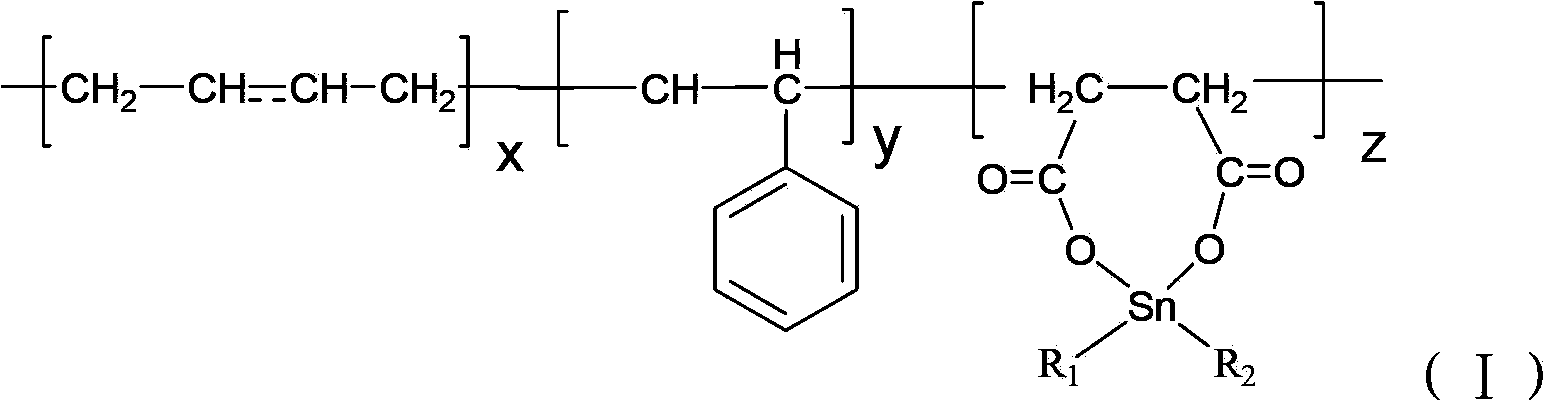

Polyvinyl chloride heat stabilizer, its preparation method and its application

A technology of polyvinyl chloride and heat stabilizer, applied in the field of new polyvinyl chloride heat stabilizer and its preparation, can solve the problems of high cost of organotin heat stabilizer, soaring metal tin price, easy dust flying, etc. The effect of stable efficiency, low cost and high thermal stabilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

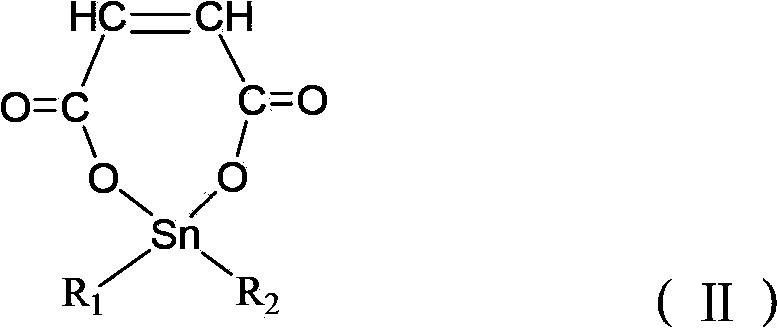

preparation Embodiment 1

[0040] Into a 250ml three-necked flask equipped with a reflux device with an oil bath temperature of 50°C, nitrogen was introduced to remove air, and then 22.5g (0.216mol) of styrene and 9.7g (0.0279mol) of dibutyltin maleate were added, and stirring was started. After dissolving into a translucent solution, add 1.7g (which contains equivalent to 0.03mol of butadiene monomer) of liquid polybutadiene (average molecular weight 1×10 3 ) into the flask, stir evenly, add 0.25g initiator (azobisisobutyronitrile), raise the temperature to 75°C, and stop the reaction for 6h after polymerization. A translucent viscous substance was obtained, diluted with 50 ml of benzene, and the reaction product was poured into a beaker containing 400 ml of methanol solution containing 0.8% hydroquinone polymerization inhibitor for precipitation. The precipitate was dissolved in benzene and then precipitated with methanol. Unreacted monomers are removed. The product was put into an electric heating c...

preparation Embodiment 2

[0042] Into a 250ml three-necked flask equipped with a reflux device with a set oil bath temperature of 50°C, nitrogen was introduced to remove the air, then 31.2g (0.3mol) of styrene and 16g (0.035mol) of dioctyltin maleate were added, and the stirrer was started. , after dissolving into a translucent solution, add 2.7g (which contains butadiene monomer equivalent to 0.05mol) liquid polybutadiene (average molecular weight 1×10 3 ) and the initiator benzoyl peroxide 0.54g, heat up to 95 °C for 8 hours to stop the reaction and obtain a translucent viscous substance. After diluting with 50ml benzene, pour the reaction product into a 400ml container containing 0.8% hydroquinone for polymerization inhibition. Precipitate in a beaker of methanol solution of the reagent, dissolve the precipitate with benzene, and then precipitate with methanol to remove unreacted monomers. The product was put into an electric heating constant temperature blast drying oven at 60°C for drying for 48 h...

preparation Embodiment 3

[0044] Into a 250ml three-necked flask equipped with a reflux device with a set oil bath temperature of 50°C, nitrogen was introduced to remove air, then 31.2g (0.3mol) of styrene and 17.4g (0.05mol) of dibutyltin maleate were added, and stirring was started. 18ml containing 2.76g (which contains the equivalent of 0.05mol of butadiene monomer) polybutadiene (average molecular weight 4.0 × 10 5 ) tetrahydrofuran solution (pre-dissolved) was added to the flask, 0.25g of initiator (azobisisobutyronitrile) was added, stirred until it became translucent, the temperature was raised to 85 °C, and a translucent viscose was obtained after constant temperature polymerization for 10 hours. Thick material, diluted with 50ml of benzene, poured the reaction product into a beaker containing 400ml of methanol solution containing 0.8% hydroquinone polymerization inhibitor to precipitate, the precipitate was dissolved with benzene, and then precipitated with methanol to remove unreacted monomer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com