Method for preparing composite wear-resistant roller

A roller and alloy powder technology, which is applied in the preparation of composite wear-resistant rollers, and in the field of composite wear-resistant rollers, can solve problems affecting the normal operation of the conveying system, short service life of metal rollers, and increased labor intensity of workers, and achieve internal organization Excellent, improved overall performance, and firm interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of a rod-shaped composite wear-resistant roller with high chromium alloy as the hard phase and A3 steel as the matrix

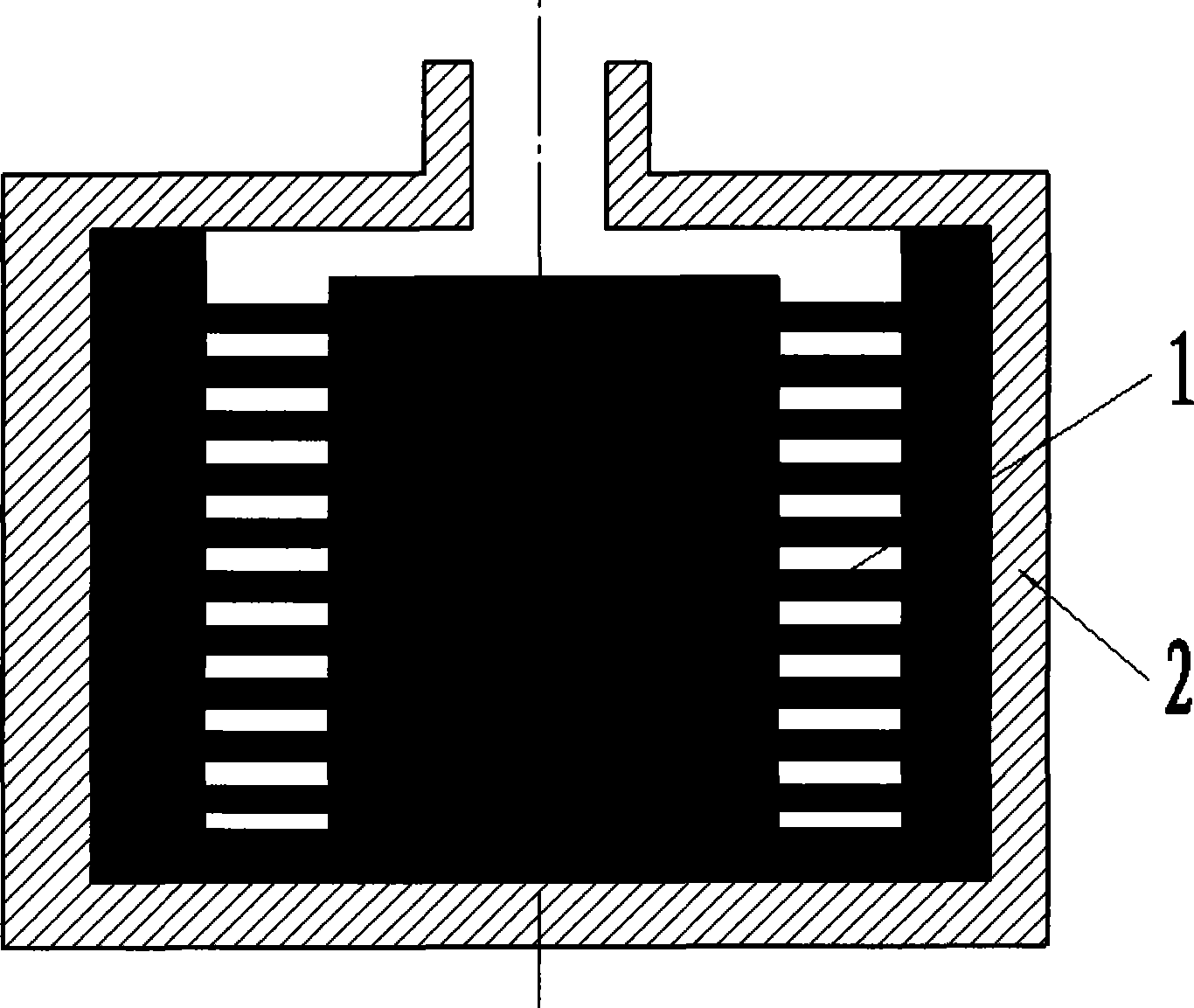

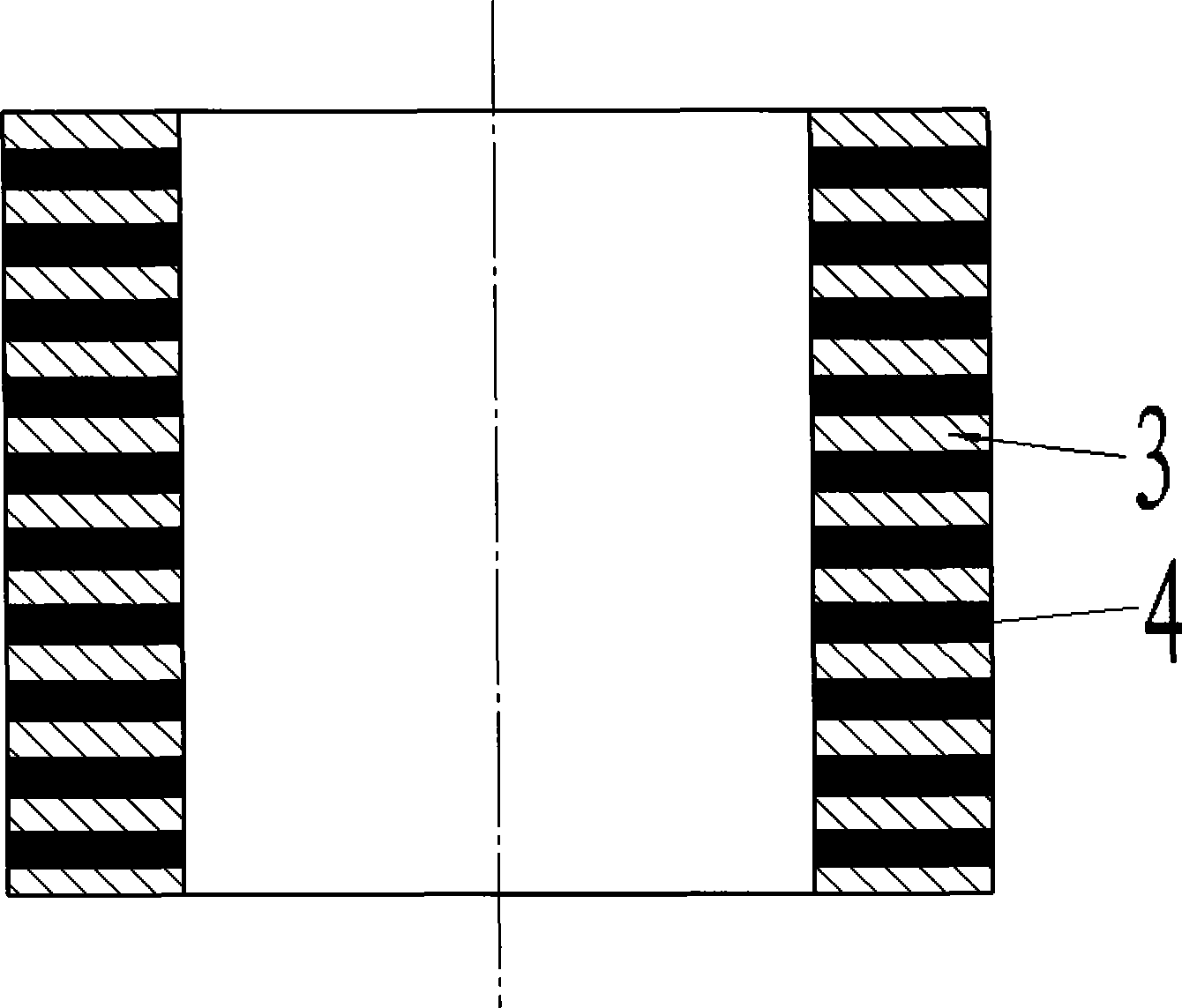

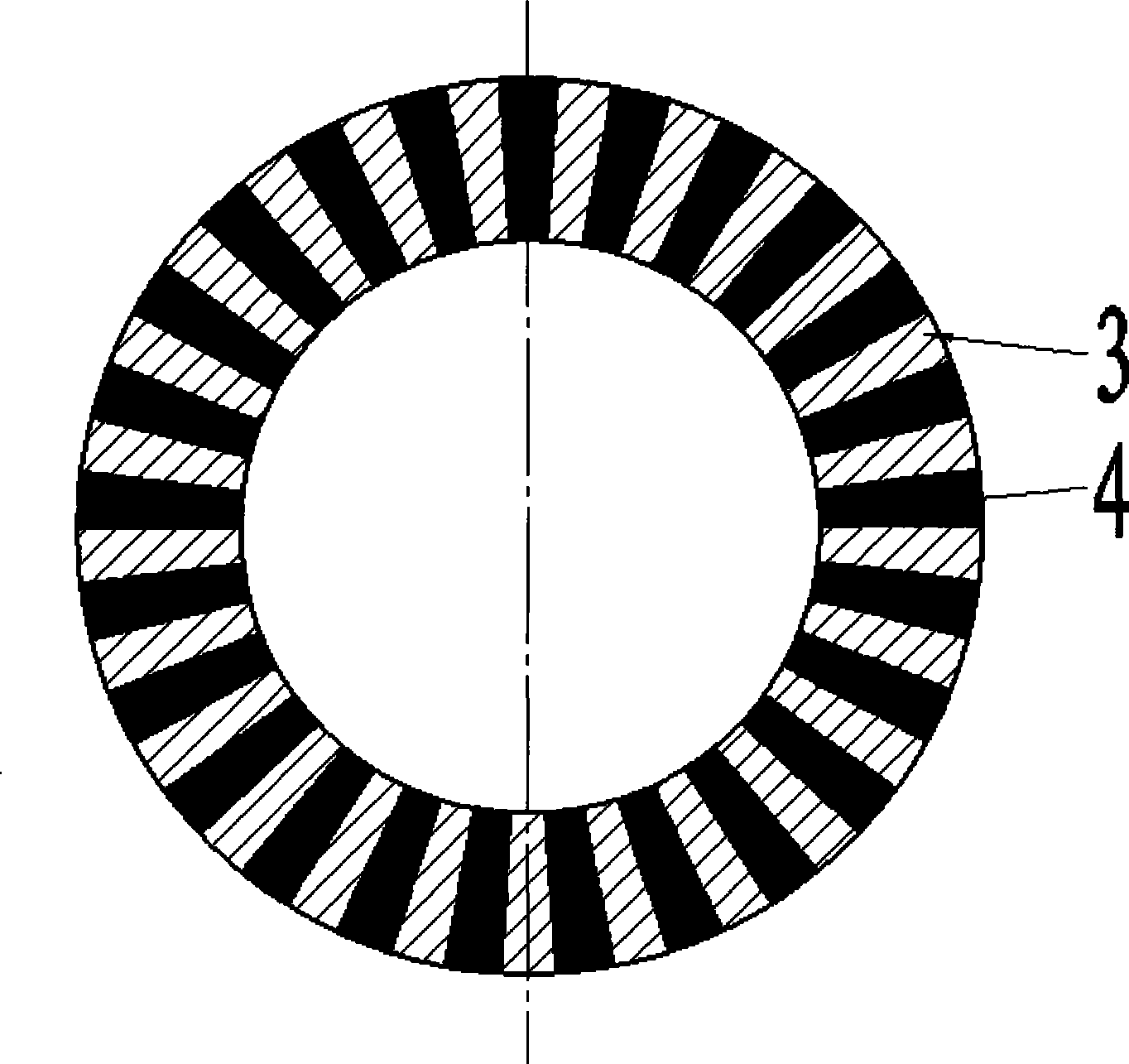

[0026] 1. Use 3mm diameter alloy powder core bar 1 to make bundles, and the loaded alloy powder is high-carbon ferrochrome powder, with a particle size of 100-150 mesh, and cut to the same height as the wall thickness of the drum;

[0027] 2. Use resin sand to make wear-resistant roller mold 2 according to the casting process requirements;

[0028] 3. The alloy powder core rod 1 is arranged in the cavity of the casting mold 2 of the wear-resistant roller according to the ratio of 50% of the volume of the wear-resistant roller;

[0029] 4. Select A3 steel as the base metal 3. After smelting and melting in an intermediate frequency furnace, it reaches 1600°C and is released from the furnace. The molten steel is poured into the cavity of the wear-resistant roller mold 2 until it is full;

[0030] 5. Cool at room temperature. After ...

Embodiment 2

[0032] Example 2: Preparation of a rod-shaped composite wear-resistant roller with tungsten carbide as the hard phase and A3 steel as the matrix

[0033] 1. Select alloy powder core rod 1 with a diameter of 5mm. The alloy powder is tungsten carbide alloy powder with a particle size of 150 mesh and cut to the same length as the drum wall thickness;

[0034] 2. Use resin sand to make mold 2 according to the casting process requirements;

[0035] 3. The alloy powder core rod 1 is preset in the cavity of the wear-resistant roller mold 2 according to the ratio of 40% of the volume of the wear-resistant roller;

[0036] 4. Select A3 steel as the base metal 3. After smelting and melting in an intermediate frequency furnace, it reaches 1600°C and is released from the furnace. The molten steel is poured into the cavity of the wear-resistant roller mold 2 until it is full;

[0037] 5. Cool at room temperature. After the molten metal is cooled and solidified, take out the casting and cl...

Embodiment 3

[0038] Example 3: Preparation of a rod-shaped composite wear-resistant roller with tungsten carbide as the hard phase and high manganese steel as the matrix

[0039] 1. Select alloy powder core rod 1 with a diameter of 3mm. The alloy powder is tungsten carbide alloy powder with a particle size of 50-80 mesh, and it is cut to the same length as the drum wall thickness;

[0040] 2. Use resin sand to make mold 2 according to the casting process requirements;

[0041] 3. The alloy powder core rod 1 is preset in the cavity of the wear-resistant roller mold 2 according to the ratio of 60% of the volume of the wear-resistant roller;

[0042] 4. Select high manganese steel Mn13 as the base metal 3. After smelting and melting in an intermediate frequency furnace, it reaches 1650°C and is released from the furnace. The molten steel is poured into the cavity of the wear-resistant roller mold 2 until it is full;

[0043] 5. Cool at room temperature. After the molten metal is cooled and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com