Metal wire for horseshoe nail and preparation method thereof

A metal wire and horseshoe technology, which is applied in the coating process of metal materials, can solve problems such as damage to organisms, and achieve the effects of improving mechanical properties, reducing energy consumption, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

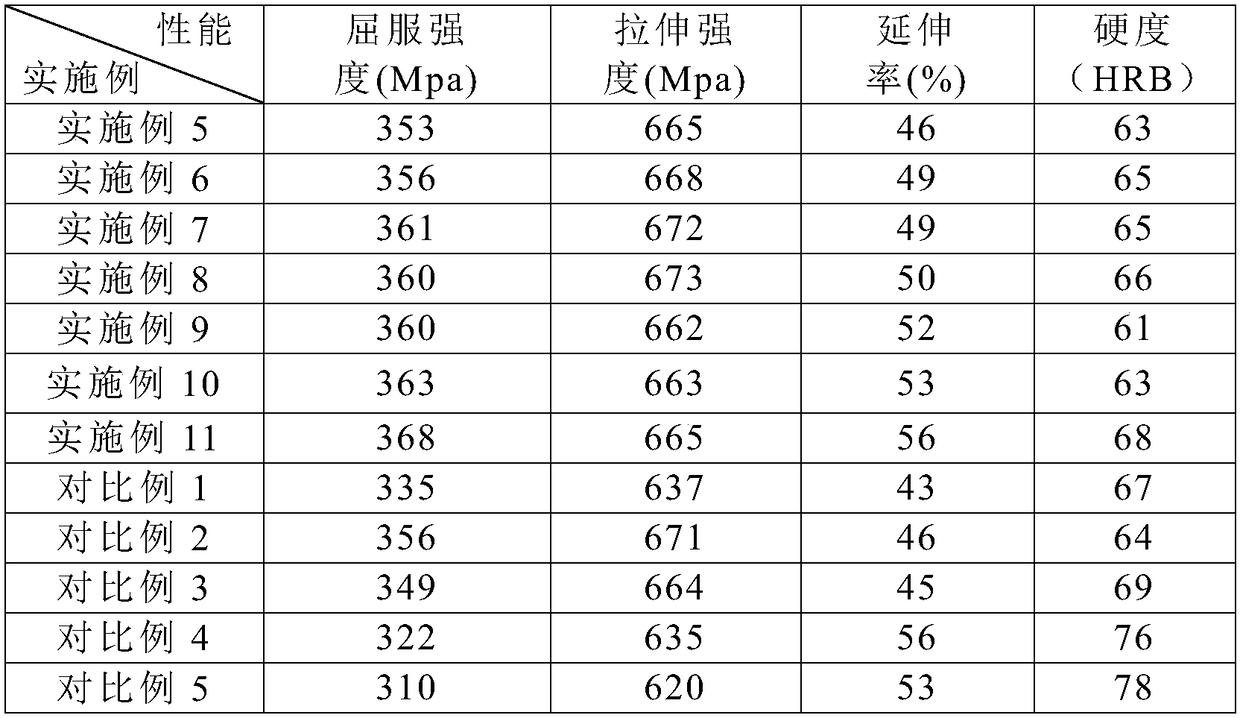

Examples

Embodiment 1

[0028] The metal wire rod for horseshoe nails in the present embodiment comprises the following components in mass percentage: 0.25% C, 8.5% Cr, 2.0% Mo, 7.6% Mn, 0.33% Ni, 1.6% nanometer CBN, 2.0% nanometer WC, 0.2% Gd, 2.3% Co, 0.33% N, 1.0% Si, P≤0.045%, 0.02% S, and the balance is Fe.

[0029] Among them, the total mass percentage of Co and nano-CBN is 4.9%. The particle diameter of nano CBN is 8-20nm, and the particle diameter of nano WC is 15-25nm. N element with C 3 N 4 form to join.

Embodiment 2

[0031]The metal wire rod for horseshoe nails in the present embodiment comprises the following components in mass percent: 0.26% C, 9.0% Cr, 2.3% Mo, 8.2% Mn, 0.38% Ni, 2.0% nano CBN, 2.2% nano WC, 0.2% Gd, 2.8% Co, 0.46% N, 0.8% Si, 0.02% P, 0.03% S, and the balance is Fe.

[0032] Wherein, the total mass percentage of Co and nano-CBN is 5.2%. The particle diameter of nano CBN is 8-20nm, and the particle diameter of nano WC is 15-25nm. N element with C 3 N 4 form to join.

Embodiment 3

[0034] The metal wire rod for horseshoe nails in the present embodiment comprises the following components in mass percent: 0.28% C, 8.9% Cr, 2.6% Mo, 9.0% Mn, 0.43% Ni, 2.3% nanometer CBN, 2.5% nanometer WC, 0.3% Gd, 3.5% Co, 0.55% N, 0.5% Si, 0.03% P, 0.02% S, and the balance is Fe.

[0035] Wherein, the total mass percentage of Co and nano-CBN is 5.0%. The particle diameter of nano CBN is 8-20nm, and the particle diameter of nano WC is 15-25nm. N element with C 3 N 4 form to join.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com