Pretreatment method for improving dyeing performance of bamboo materials

A dyeing performance, bamboo technology, applied in wood treatment, wood low temperature treatment, wood treatment details, etc., can solve the problems of light color, easy color fading, false color, etc., to change the cellulose structure, increase the dyeing stability, dye up rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

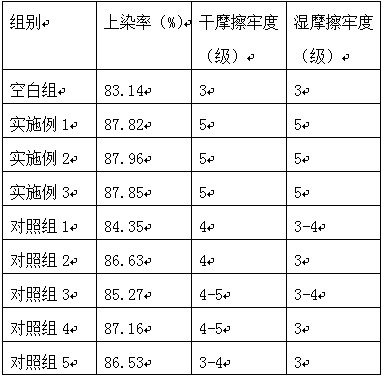

Examples

Embodiment 1

[0017] A pretreatment method for improving bamboo dyeing performance, comprising the following contents:

[0018] (1) Put the bamboo raw material in a hydrochloric acid aqueous solution with a mass concentration of 7%, vacuumize it to 0.07MPa, keep it for 25 minutes, pressurize it to 0.55MPa, and keep the pressure for 3.5 hours. Microwave treatment for 15 minutes under power conditions;

[0019] (2) Treat the bamboo after the above treatment at -10°C for 50 minutes;

[0020] (3) Place the frozen bamboo in a treatment agent at a temperature of 45°C, vacuumize to a negative pressure of 0.06MPa, keep it for 50 minutes, take it out, and set aside;

[0021] The treatment agent includes the following raw materials in parts by weight: 3 parts of propylene glycol methyl ether acetate, 8 parts of hydroxycarboxylic acid, 2 parts of siloxane coupling agent, 1.2 parts of 1,3-propyl sultone, 0.4 parts of sodium benzoate 0.2 parts of 2,3,5-trimethylpyrazine, 100 parts of water;

[0022] ...

Embodiment 2

[0027] A pretreatment method for improving bamboo dyeing performance, comprising the following contents:

[0028] (1) Put the bamboo raw material in an aqueous hydrochloric acid solution with a mass concentration of 8%, evacuate it to 0.06MPa, keep it for 30 minutes, pressurize it to 0.45MPa, and keep the pressure for 4 hours. Microwave treatment under power conditions for 18 minutes;

[0029] (2) Treat the bamboo after the above treatment at -10°C for 60 minutes;

[0030] (3) Place the frozen bamboo in a treatment agent at a temperature of 42°C, evacuate to a negative pressure of 0.06 MPa, keep it for 60 minutes, take it out, and set aside;

[0031] The treatment agent includes the following raw materials in parts by weight: 4 parts of propylene glycol methyl ether acetate, 10 parts of hydroxycarboxylic acid, 1 part of siloxane coupling agent, 1.6 parts of 1,3-propyl sultone, 0.2 parts of sodium benzoate 0.3 parts of 2,3,5-trimethylpyrazine, 100 parts of water;

[0032] (4...

Embodiment 3

[0037] A pretreatment method for improving bamboo dyeing performance, comprising the following contents:

[0038] (1) Put the bamboo raw material in an aqueous hydrochloric acid solution with a mass concentration of 8%, evacuate to 0.08MPa, keep it for 20 minutes, pressurize to 0.65MPa, and keep the pressure for 4 hours. Microwave treatment under power conditions for 12 minutes;

[0039] (2) Treat the bamboo after the above treatment at -10°C for 40 minutes;

[0040] (3) Place the frozen bamboo in a treatment agent at a temperature of 48°C, evacuate to a negative pressure of 0.06 MPa, keep it for 40 minutes, take it out, and set aside;

[0041] The treatment agent includes the following raw materials in parts by weight: 2 parts of propylene glycol methyl ether acetate, 6 parts of hydroxycarboxylic acid, 3 parts of siloxane coupling agent, 0.8 part of 1,3-propyl sultone, 0.6 part of sodium benzoate 0.1 part of 2,3,5-trimethylpyrazine, 100 parts of water;

[0042] (4) Place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com