Fiber costume material with antibacterial health function and preparation technology of fiber costume material

A preparation process and fiber material technology, which is applied in the field of textile and clothing materials, can solve the problems of low release efficiency, bactericidal and antibacterial restrictions, etc., and achieve the effects of sterilizing cell growth, inhibiting oxidation, and promoting cell growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

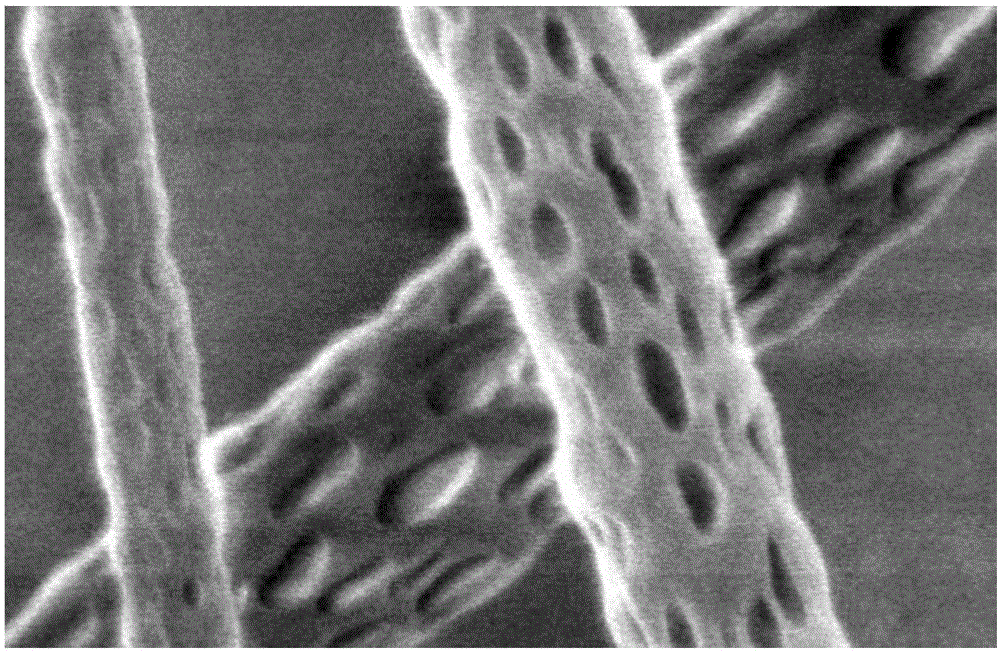

Image

Examples

Embodiment I

[0038] Take polylactic acid (PLLA), polycarbonate (PC) and polyvinylcarbazole (Polyvinylcarbazole) and dissolve them in dichloromethane at room temperature to obtain a mixed spinning solution; wherein PLLA is in the mixed spinning solution The mass concentration of PC is 3-5wt%, the mass concentration of PC is 12-15wt%, and the concentration of polyvinylcarbazole is 6-8wt%;

[0039] Put the mixed spinning solution into an electrostatic spinning machine, and perform jet drawing under the action of a strong electric field to obtain an intermediate fiber material; the drawing speed is 2-5 m / s, the environmental temperature of the drawing process is 20-25 degrees Celsius, and the electric field The intensity is 10KV. In the electrospinning process, the electric field force overcomes the surface tension of the tiny droplets of the spinning solution to form a droplet form suitable for spinning. Dichloromethane evaporates quickly. PLLA, PC and Polyvinylcarbazole have poor compatibility ...

Embodiment II

[0045] Take polyvinylpyrrolidone (PVP) and polyvinylidene fluoride (PVDF) into dimethylformamide (DMF) to prepare a mixed solution as a spinning solution; the mass-volume ratios of the above three in the mixed solution are: PVP10g: PVDF20g: DMF100mL, that is, add 10gPVP and 20gPVDF to every 100mL of DMF.

[0046] Put the spinning solution into the electrospinning machine and perform jet drawing under the action of a strong electric field to obtain an intermediate fiber material; the drawing speed is 2-5 m / s, and the environmental temperature of the drawing process can be kept at room temperature, and the electric field strength is 15KV. After electrospinning and drawing, it is placed in a vacuum environment for drying to promote the volatilization of the solvent and form an intermediate fiber material with a high density of holes. In the process of electrospinning, because PVP and PVDF are incompatible with each other, the two are separated and enriched. DMF as a solvent is fully...

Embodiment III

[0051] Take polyacrylonitrile (PAN) and polyethylene oxide (PEO) into dimethylformamide (DMF), and prepare a mixed solution at a constant temperature of 80 degrees Celsius; the mass concentration of PAN in the mixed solution is 4wt%-7wt %, preferably 6.8wt%; the mass concentration of PEO in the mixed solution is 1.2wt%-4.0wt%; the total mass concentration of both PAN and PEO in the mixed solution remains 8wt%; the mixed solution is used as a spinning solution.

[0052] Put the spinning solution into the electrospinning machine and perform jet drawing under the action of a strong electric field; the temperature can be kept at room temperature. During the drawing process, the electric field strength is 8KV and the fiber obtained after drawing is placed in a vacuum for 24 hours to allow the residual DMF solvent on the fiber Volatile; further, the fiber is immersed in a water bath of deionized water at 70 degrees Celsius for 10 minutes to remove the PEO in the fiber. Holes are formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com