Anti-staining epoxy fire-retardant coating and preparation method thereof

A fire-resistant coating and anti-fouling technology, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems that the stains cannot be cleaned, the corrosion resistance and aesthetics of the steel structure are affected, and the anti-fouling performance is not considered. , to achieve the effect of being conducive to cleaning, excellent anti-fouling, and improving anti-fouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

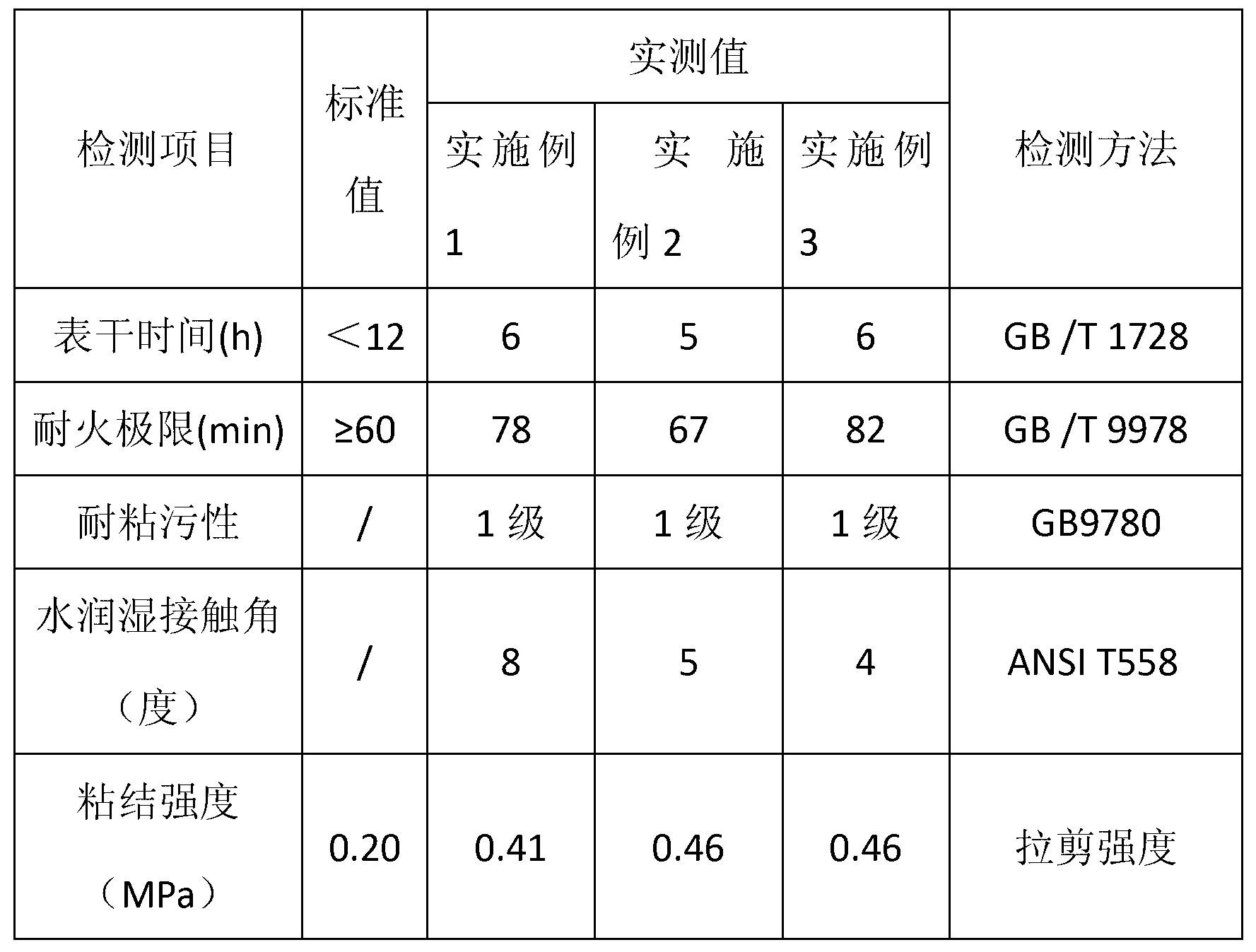

Examples

Embodiment 1

[0019] An antifouling type epoxy resin fireproof coating is composed of A component and B component, wherein A component includes by weight percentage: 400g of nonionic emulsifier emulsified with a solid content of 50% and an epoxy equivalent of 1200 epoxy resin (Yueyang Petrochemical General Plant CYD112-W50), 150g of modified ammonium polyphosphate, 75g of melamine, 75g of pentaerythritol, 50g of crystal redite nano-titanium dioxide, 30g of nano-silica, 50g of silane Joint agent KH-560, 150g of brucite fiber with a fiber length of less than 1mm, and deionized water as the balance; component B is a mixture of 40g of triethanolamine and polyetheramine D400 with a mass ratio of 2:1.

[0020] The preparation method of the above-mentioned fireproof coating: epoxy resin emulsified by a non-ionic emulsifier with a solid content of 50% and an epoxy equivalent of 1200, crystal redite nano-titanium dioxide, nano-silica and silane coupling agent KH-560 Put it into a high shear emulsifi...

Embodiment 2

[0022] An antifouling type epoxy resin fireproof coating is composed of A component and B component, wherein A component includes by weight percentage: 400g of nonionic emulsifier emulsified with a solid content of 50% and an epoxy equivalent of 1800 epoxy resin (Yueyang Petrochemical General Plant CYD112-W50), 150g of modified ammonium polyphosphate, 75g of melamine, 75g of pentaerythritol, 70g of crystal redite nano-titanium dioxide, 30g of nano-silica, 60g of silane Joint agent KH550, 100g of brucite fiber with a fiber length of less than 1mm, the balance is deionized water; component B is a mixture of 40g of triethanolamine and polyetheramine D400 with a mass ratio of 2:1.

[0023] The preparation method of the above-mentioned fireproof coating: adding epoxy resin emulsified by a non-ionic emulsifier with a solid content of 50% and an epoxy equivalent of 1800, crystal redite nano-titanium dioxide, nano-silica and silane coupling agent KH550 into high Disperse for 45 minute...

Embodiment 3

[0025] An antifouling type epoxy resin fireproof coating is composed of A component and B component, wherein A component includes by weight percentage: 450g of nonionic emulsifier emulsified with a solid content of 50% and an epoxy equivalent of 1400 epoxy resin (Yueyang Petrochemical General Plant CYD112-W50), 150g of modified ammonium polyphosphate, 75g of melamine, 75g of pentaerythritol, 70g of crystal redite nano-titanium dioxide, 50g of nano-silica, 70g of silane Joint agent KH-560, 150g of brucite fiber with a fiber length of less than 1mm and deionized water as the balance; component B is a mixture of 45g of triethanolamine and polyetheramine D400 with a mass ratio of 2:1.

[0026] The preparation method of the above-mentioned fireproof coating: epoxy resin emulsified by a non-ionic emulsifier with a solid content of 50% and an epoxy equivalent of 1400, crystal red stone nano-titanium dioxide, nano-silica and silane coupling agent KH-560 Put it into a high shear emulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com