A kind of carbon nanotube/nanometer silver solder paste heat conduction material and preparation method thereof

A technology of carbon nanotubes and heat-conducting materials, applied in the direction of welding/cutting media/materials, welding equipment, manufacturing tools, etc., to achieve the effect of improving wettability, good application prospects, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

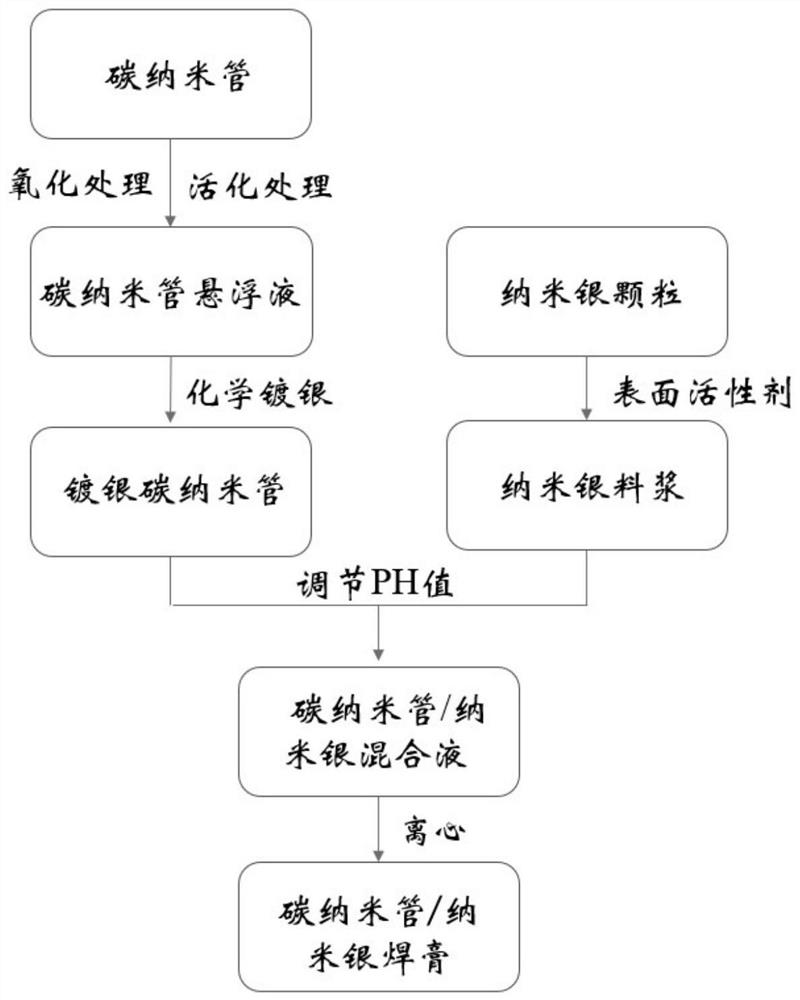

Method used

Image

Examples

Embodiment 1

[0030] (1) Carrying out oxidation treatment and activation treatment on the carbon nanotube particles. Add 0.8g nano-carbon nanotube particles to the K of 0.35mol / L 2 Cr 2 o 7 Solution mixed with 0.25mol / L HCl solution, boiled at 70°C for 8h for oxidation treatment. Then place the oxidized carbon nanotubes in 0.024mol / L PdCl 2 Activation treatment is carried out in the solution, and finally the activated carbon nanotubes are repeatedly washed with deionized water until they become neutral;

[0031] (2) Electroless silver plating is performed on the carbon nanotube particles. At room temperature, add 0.06mol / L silver nitrate solution dropwise to analytically pure ammonia water with a concentration of 25% to configure the silver ammonia solution, then add activated carbon nanotube particles to the silver ammonia solution, and magnetically Stir, adjust the pH value of the mixed oxidation solution to 8, and finally add dropwise a formaldehyde solution with a concentration of ...

Embodiment 2

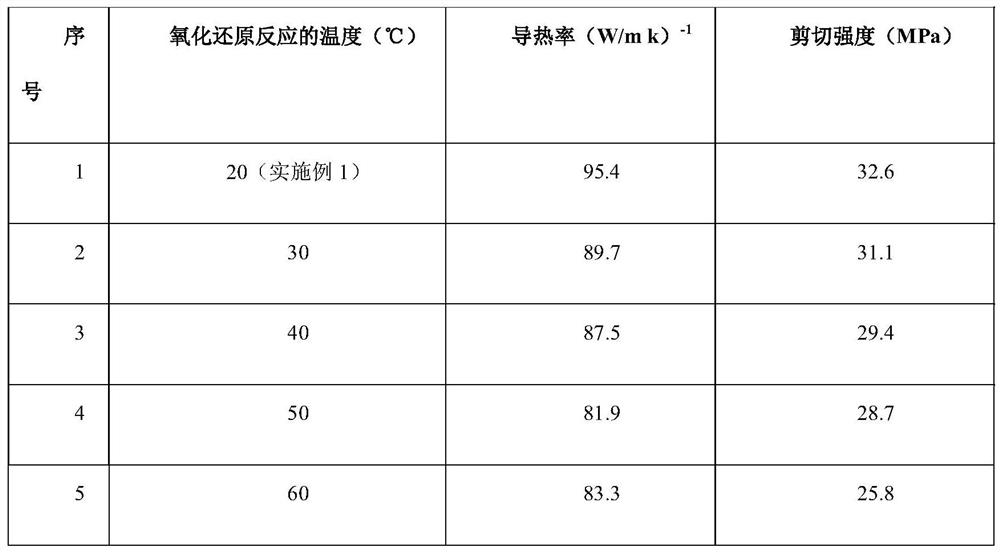

[0036] Other conditions are the same as in Example 1, and the properties of the materials prepared at different redox reaction temperatures are tested. The experimental results are shown in Table 1.

[0037] Table 1 Performance of thermally conductive materials at different redox reaction temperatures

[0038]

[0039] From the above results, it can be seen that the temperature ratio of the oxidation-reduction reaction is preferably 20° C. (Example 1).

Embodiment 3

[0041] Other conditions are the same as in Example 1, and the properties of the materials prepared with different pH values of the mixed oxidation solution systems are tested, and the experimental results are shown in Table 2.

[0042] Table 2 The pH value of the mixed oxidation solution system on the performance of thermally conductive materials

[0043]

[0044]

[0045] From the above results, it can be seen that the pH ratio of the mixed oxidation solution system is preferably 8.0 (Example 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com