Layered ceramic composite material based on silicon nitride, and preparation method thereof

A technology of ceramic composite materials and silicon nitride, which is applied in the field of ceramic materials, can solve problems such as limiting the application of silicon nitride materials, and achieve the effects of overcoming fracture problems, improving brittleness, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

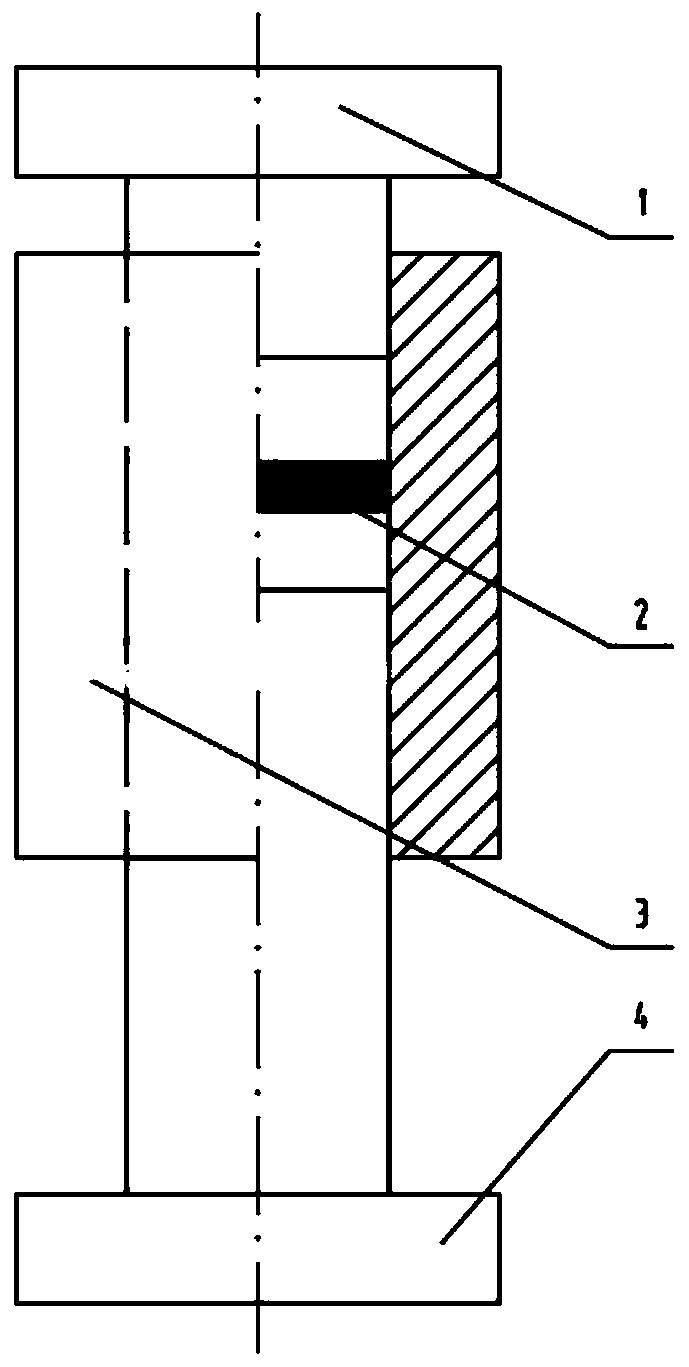

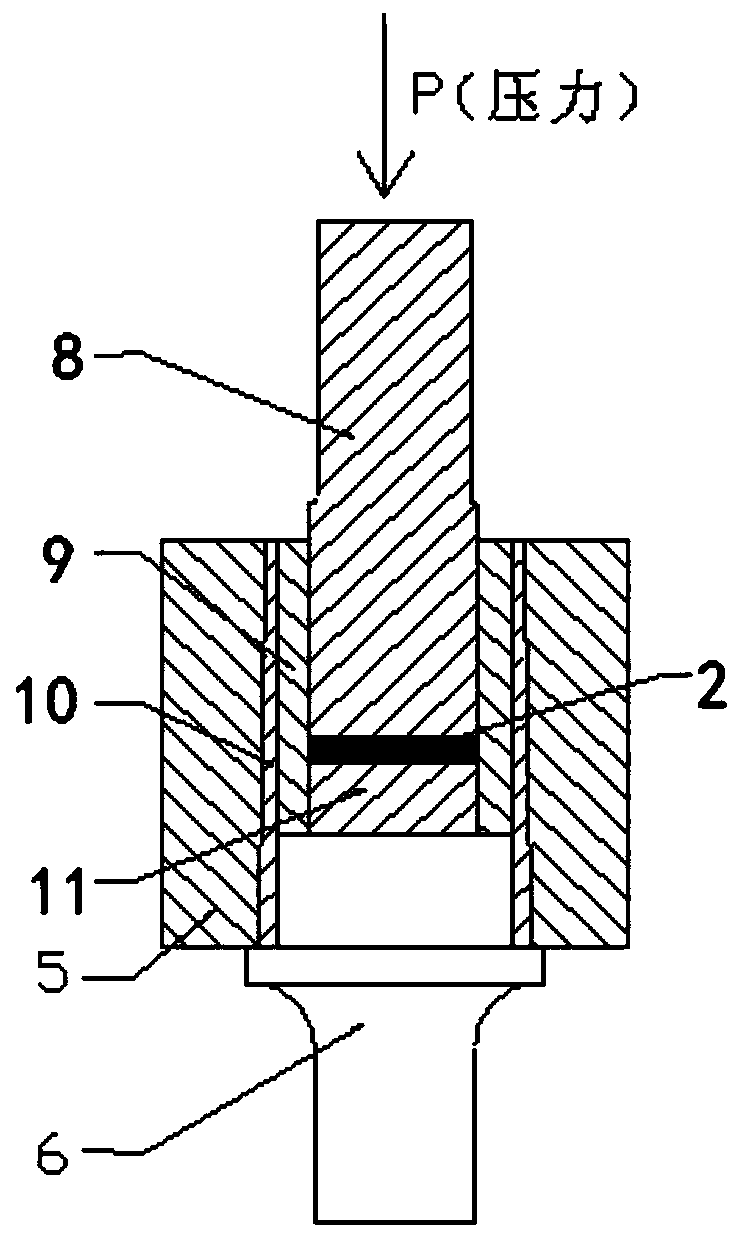

Method used

Image

Examples

Embodiment 1

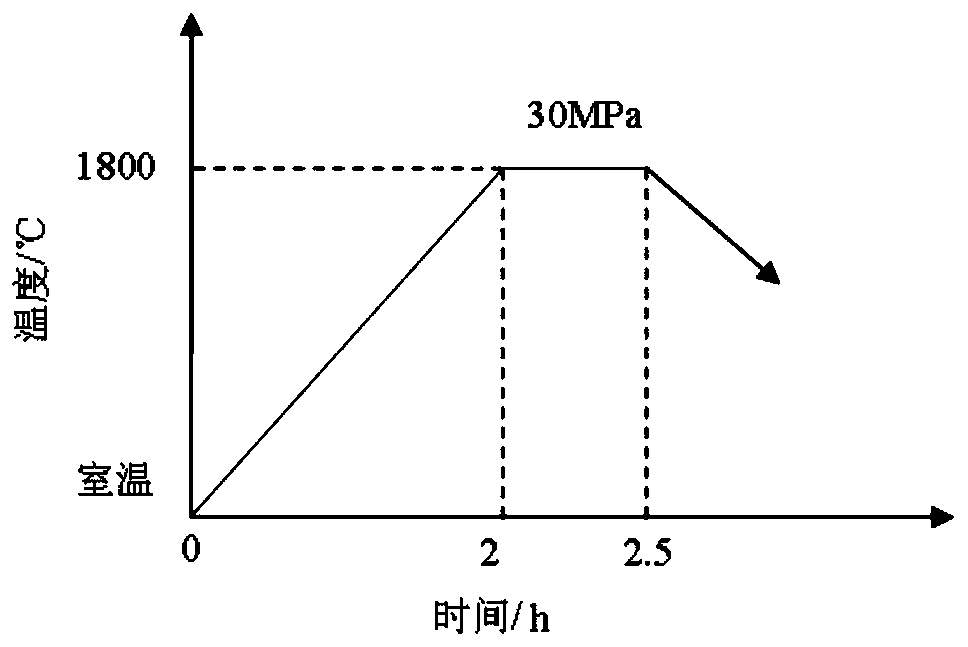

[0037] A method for preparing a layered ceramic composite material based on silicon nitride, comprising the following steps:

[0038] 1) Ingredients: Weigh 24.56g of silicon nitride and 2.72g of Al according to the mass ratio 2 o 3 and Y 2 o 3 A mixture of sintering aids, and 8.25g of molybdenum powder. Among them, the purity of silicon nitride is 99.99%, the α phase is >94%, the average particle size is 0.3 μm, and the volume fraction is 90%, the purity of hexagonal boron nitride is 99.6%, the average particle size is 0.5 μm, Al 2 o 3 and Y 2 o 3 Purity>99.5%, average particle size 1μm, Al 2 o 3 1.63g, Y 2 o 3 It is 1.09g.

[0039] 2) Ball mill mixing: the weighed silicon nitride and Al 2 o 3 with Y 2 o 3 Put the sintering aid powder of the mixture in a ball mill jar, add zirconia balls, pour alcohol, adjust the fluid viscosity, and use a planetary ball mill to mix well at a speed of 50r min -1 , the ball milling time is 5h; wherein, the amount of zirconia bal...

Embodiment 2

[0049] A preparation method of a layered ceramic composite material based on silicon nitride, comprising the following steps:

[0050] Step 1) Ingredients: Weigh 25.0g of silicon nitride and 2.77g of Al according to mass ratio 2 O 3 and Y 2 O 3 Mixed sintering aid, and 6.87g of molybdenum powder. Among them, the purity of silicon nitride is 99.99%, the α phase is >94%, the average particle size is 0.3 μm, the volume fraction is 90%, the purity of hexagonal boron nitride is 99.6%, the average particle size is 0.5 μm, Al 2 O 3 and Y 2 O 3 Purity >99.5%, average particle size of 1μm, Al 2 O 3 1.66g, Y 2 O 3 is 1.11g.

[0051] Step 2) Ball-milling mixture: weighed silicon nitride and Al 2 O 3 with Y 2 O 3 The mixture of sintering aid powder is placed in a ball mill jar, zirconium dioxide balls are added, alcohol is poured in, the viscosity of the fluid is adjusted, and a planetary ball mill is used to fully mix at a speed of 100r·min -1 , the ball milling time is 5...

Embodiment 3

[0061] A preparation method of a layered ceramic composite material based on silicon nitride, comprising the following steps:

[0062] Step 1) Ingredients: Weigh 25.46g of silicon nitride and 2.83g of Al according to mass ratio 2 O 3 and Y 2 O 3 Mixed sintering aid, and 5.47g of molybdenum powder. Among them, the purity of silicon nitride is 99.99%, the α phase is >94%, the average particle size is 0.3 μm, the volume fraction is 90%, the purity of hexagonal boron nitride is 99.6%, the average particle size is 0.5 μm, Al 2 O 3 and Y 2 O 3 Purity >99.5%, average particle size of 1μm, Al 2 O 3 1.13g, Y 2 O 3 is 1.70g.

[0063] Step 2) Ball-milling mixture: weighed silicon nitride and Al 2 O 3 with Y 2 O 3 The mixture of sintering aid powder is placed in a ball mill jar, zirconium dioxide balls are added, alcohol is poured in, the viscosity of the fluid is adjusted, and a planetary ball mill is used to fully mix at a speed of 150r·min -1 , the ball milling time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com