Lightweight high-strength foam concrete

A foam concrete, high-strength technology, applied in the field of concrete, can solve the problem of poor bonding performance between polypropylene fiber and cement matrix, and achieve the effect of improving hydrophilicity and cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of lightweight high-strength foam concrete, comprising the following steps:

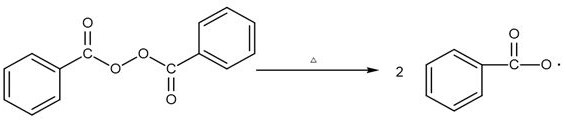

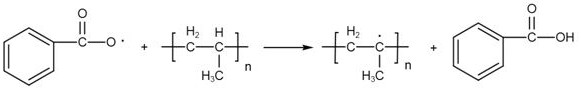

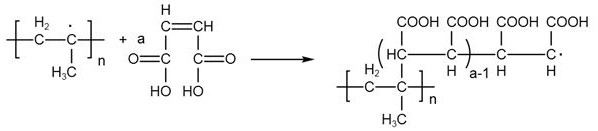

[0052] S1. 30g dibenzoyl peroxide is added in xylene solution, is mixed with the dibenzoyl peroxide solution of 0.3mol / L concentration.

[0053] S2. Continuously feed nitrogen into the flask at a rate of 80 g / min, and add the dibenzoyl peroxide solution and polypropylene fibers into the flask.

[0054]S3. Stir the polypropylene fiber and dibenzoyl peroxide solution under a nitrogen atmosphere, then heat up to 50°C, swell at a constant temperature for 45 minutes, continue to heat up the dibenzoyl peroxide solution to 60°C, and react at a constant temperature for 30 minutes to obtain polypropylene- A solid-liquid mixture of dibenzoyl peroxide.

[0055] S4. After draining the liquid in the solid-liquid mixture, pour 2500g of absolute ethanol into the solid for washing, and then add 800g of water for washing after the absolute ethanol washing is completed to obtain polypropyl...

Embodiment 2

[0062] A preparation method of lightweight high-strength foam concrete, comprising the following steps:

[0063] S1. 30g dibenzoyl peroxide is added in xylene solution, is mixed with the dibenzoyl peroxide solution of 0.3mol / L concentration.

[0064] S2. In the flask, continue to feed nitrogen gas at a rate of 100 g / min, and add the dibenzoyl peroxide solution and polypropylene fibers into the flask.

[0065] S3. Stir the polypropylene fiber and dibenzoyl peroxide solution under a nitrogen atmosphere, then heat up to 55°C, and swell at a constant temperature for 47 minutes; continue to heat up the dibenzoyl peroxide solution to 75°C, and react at a constant temperature for 35 minutes to obtain polypropylene- A solid-liquid mixture of dibenzoyl peroxide.

[0066] S4. After draining the liquid in the solid-liquid mixture, pour 3000g of absolute ethanol into the solid for washing, and then add 900g of water for washing after the absolute ethanol washing is completed, to obtain p...

Embodiment 3

[0073] A preparation method of lightweight high-strength foam concrete, comprising the following steps:

[0074] S1. 30g dibenzoyl peroxide is added in xylene solution, is mixed with the dibenzoyl peroxide solution of 0.3mol / L concentration.

[0075] S2. In the flask, continue to feed nitrogen gas at a speed of 120g / min, and add the dibenzoyl peroxide solution and polypropylene fibers into the flask.

[0076] S3. Stir the polypropylene fiber and dibenzoyl peroxide solution under a nitrogen atmosphere, then heat up to 60°C, swell at a constant temperature for 50 minutes, continue to heat up the dibenzoyl peroxide solution to 90°C, and react at a constant temperature for 40 minutes to obtain polypropylene- A solid-liquid mixture of dibenzoyl peroxide.

[0077] S4. After draining the liquid in the solid-liquid mixture, pour 3500g of absolute ethanol into the solid for washing, and then add 1000g of water for washing after the absolute ethanol washing is completed to obtain polyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com