Prefabricated assembly type concrete wallboard and connecting structure and construction method thereof

A technology for prefabricating and connecting structures, applied in the direction of walls, building components, building structures, etc., can solve the problems of complex construction process, poor waterproof effect, low production efficiency, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

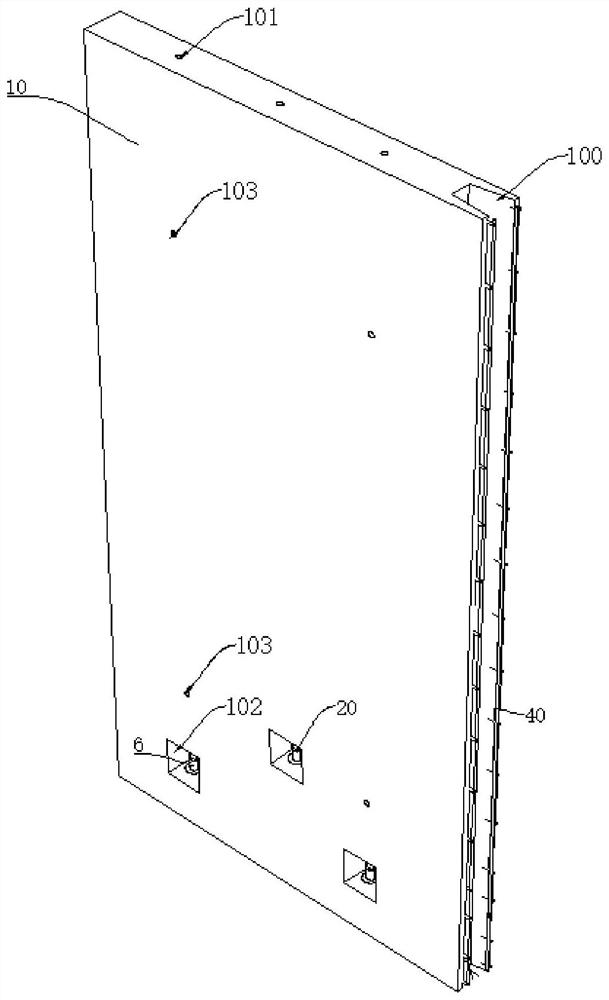

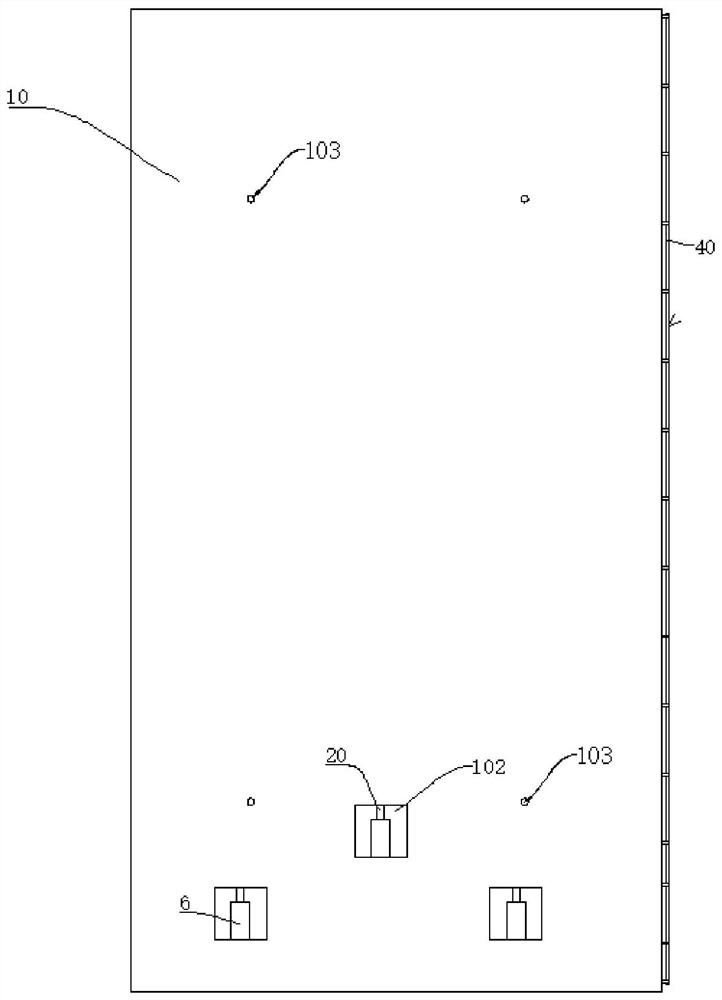

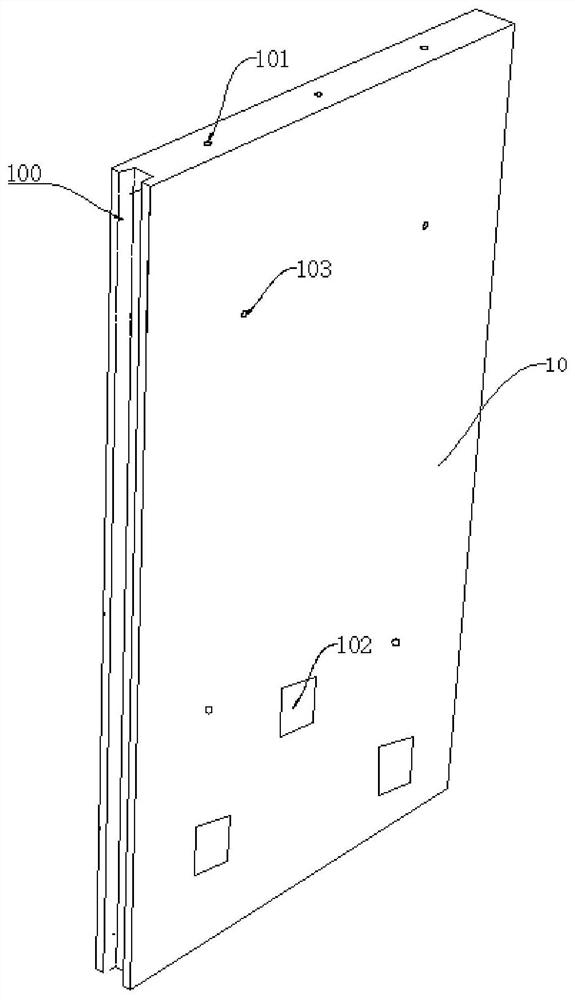

[0037] Such as Figure 1 ~ Figure 4 As shown, a prefabricated assembled concrete wall panel connection structure includes several prefabricated assembled concrete wall panels. The prefabricated concrete wall panel includes a wall panel body 10, which is rectangular in shape, and a steel skeleton is pre-embedded inside the wall panel body 10, and the steel skeleton can reinforce the wall structure.

[0038] The wallboard body 10 is provided with several vertically arranged steel bar perforations 101, the steel bar perforations 101 run through the wallboard body 10 up and down, the steel bar perforations 101 are evenly arranged, and any two adjacent connection holes 102 are arranged in a staggered manner. Set aside construction space to facilitate construction, and reserve at least 4 times the diameter of the connecting steel bar 20 in the prefabricated wall. Since the space in the steel bar perforation 101 is relatively large, the fault tolerance is strong, and the stressed ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com