Copper-based powder metallurgical pantograph sliding plate material taking spherical chromium powder as strengthening phase and preparation method thereof

A technology of pantograph sliding plate and powder metallurgy, which is applied in the field of copper-based powder metallurgy pantograph sliding plate material and its preparation, can solve the problems of expensive plasma discharge sintering system, cost reduction, industrialized production, and complicated processing technology, and achieve Improve the performance of anti-arc ablation, increase the density of the green body, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

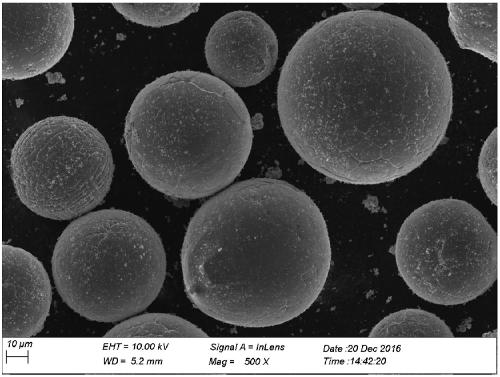

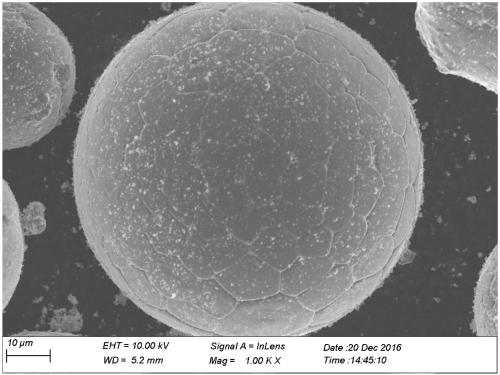

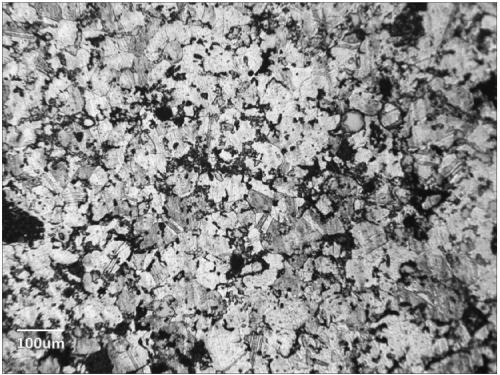

Image

Examples

Embodiment 1

[0032] According to the following mass percentages: Cu 87.5wt%, spherical Cr 2wt%, Sn 7wt%, Ni 3wt%, graphite 0.5wt%, weigh the powder, pre-mix it on an ordinary horizontal mixer for 2 hours, and then put the powder into V-shaped The materials were mixed in the mixer for 2 hours, cold-pressed at 800MPa, sintered in the atmosphere of decomposed ammonia, and kept at 950°C for 2 hours; then air-cooled in the furnace to obtain the copper-based powder metallurgy sliding plate material.

Embodiment 2

[0034] According to the following mass percentages: Cu 87wt%, spherical Cr 2wt%, Sn 7wt%, Ni 3wt%, graphite 1wt%, weigh the powder, pre-mix it on an ordinary horizontal mixer for 2 hours, and then put the powder into the V-type mixer Mix the material for 2 hours, cold press it at 800MPa, sinter in the atmosphere of decomposed ammonia, and keep it at 950°C for 2 hours; then air-cool in the furnace to obtain the copper-based powder metallurgy sliding plate material.

Embodiment 3

[0036] According to the following mass percentages: Cu 86wt%, spherical Cr 2wt%, Sn 7wt%, Ni 3wt%, graphite 2wt%, weigh the powder, pre-mix it on an ordinary horizontal mixer for 2 hours, and then put the powder into the V-type mixer Mix the material for 2 hours, cold press it at 800MPa, sinter in the atmosphere of decomposed ammonia, and keep it at 950°C for 2 hours; then air-cool in the furnace to obtain the copper-based powder metallurgy sliding plate material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com