s@m x sns y @c Composite cathode active materials and their preparation and application in lithium-sulfur batteries

A lithium-sulfur battery and composite positive electrode technology, which is applied in the direction of lithium batteries, active material electrodes, positive electrodes, etc., can solve the problems of capacity loss, poor conductivity, etc., and achieve the effect of improving capacity, improving conductivity, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

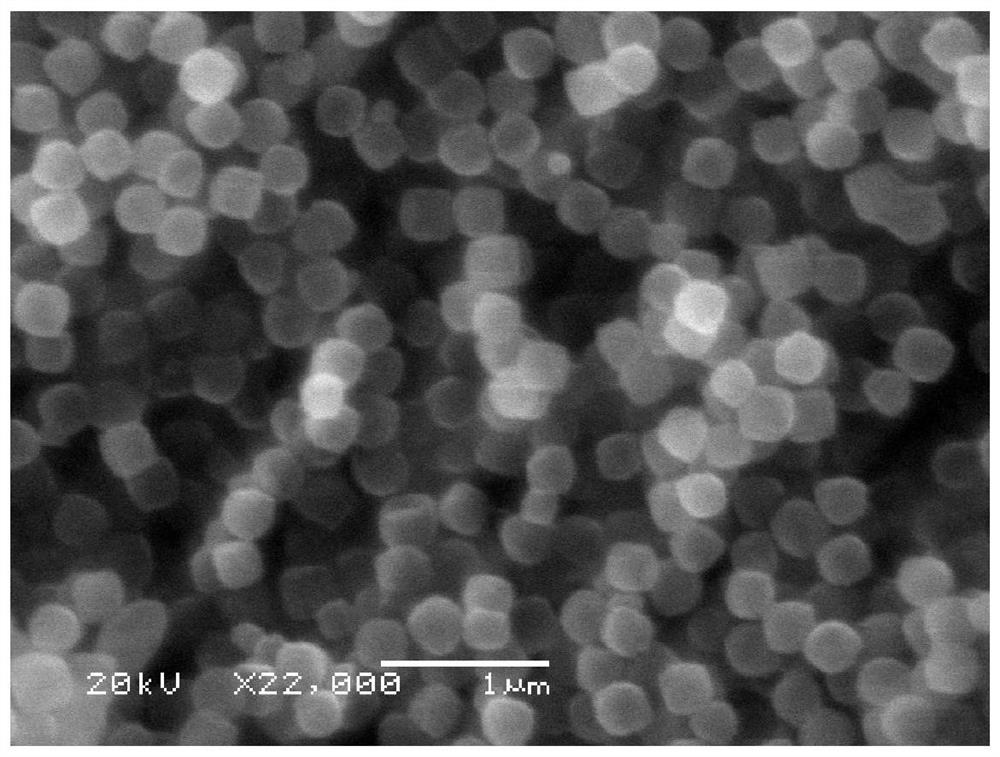

[0074](1) 0.5 mmol 5 hydrazine tin solution was dissolved in 5 ml of ethanol, and 30 ml of stirring was added to aqueous solution containing 0.5 mmol of cobalt cobalt cobalt and 0.5 mmol sodium citrate, then dripping sodium hydroxide. The solution was carried out, and the alkali concentration in the co-precipitation reaction was controlled to 1 m; the mixture was added to 0.5 h after 0.5 h, the etching reaction was carried out, and the concentration of the base during the control reaction was 9m. After 20 min, the reaction product was filtered, washed, washed in a drying tank at 80 ° C for 6 h, resulting in hollow COSN (OH)6Nano cube;

[0075](2) Take 0.4g CoSN (OH)6Dispersed in 50 ml of deionized water, then 1.5 g pdda, 0. 32 g of Tris and 0.14 g of sodium chloride were added, stirred for 120 min, then washed 3 times with deionized water to remove excess PDDA, and will carry a positively charged COSN (OH)6The nano block was added to an oxide solution having a concentration of 2 mg / m...

Embodiment 2

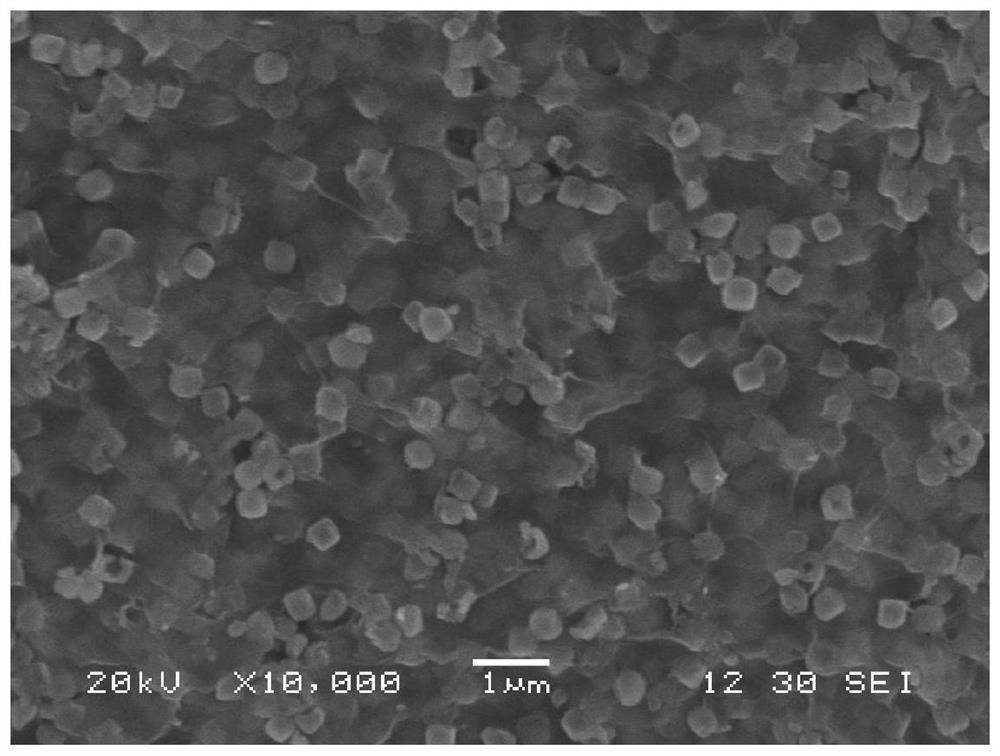

[0080](1) Take 1.5 mmol of pentahydrochloride in 5 ml of ethanol, add 30 ml of 30 ml of cobalt-containing cobalt-containing cobalt and 1.5 mmol, then drip sodium hydroxide. The solution was carried out, and the alkali concentration in the co-precipitation reaction was controlled; the mixture was added to 1.5 h, and a higher concentration of sodium hydroxide solution was added, the etching reaction was carried out, and the concentration of the base during the control reaction was 11m. After 40 min, the reaction product was filtered, washed, and then dried in a drying tank at 80 ° C for 6 h, resulting in a hollow COSN (OH) 6 nano cube;

[0081](2) 0.4 g of COSN (OH) 6 was dispersed in 50 ml of deionized water, then 2.5 g pdda, 0. 4 g of Tris and 0.18 g of sodium chloride were added, stirred for 120min, then washed 3 times with deionized water to remove excess PDDA , Then take positively charged COSN (OH)6The nano block was added to a graphene solution having a concentration of 4 mg / ml,...

Embodiment 3

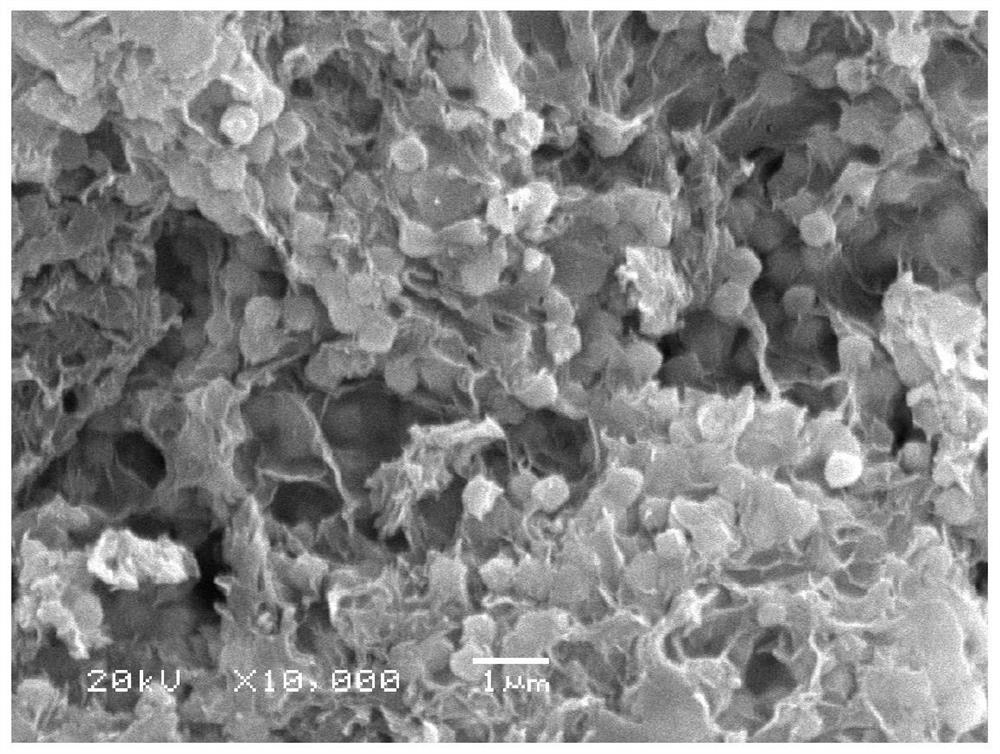

[0086](1) Take 1 mmol of penthyfrobinated tin solution in 5 ml of ethanol, dripping 30 ml of 30 ml of 1 mmol hexaloride and 1 mmol of cobalt cobalt citrate, then dripped sodium hydroxide solution, The coprecipitation reaction, the alkali concentration in the coprecipitation reaction is 2 m; the stirring reaction is added to 1 h after 1 h, the etching reaction is carried out, the concentration of the base during the control reaction is 9m, and the reaction is 30 min, The reaction product was filtered, washed, placed in a drying tank at 80 ° C for 6 h, resulting in hollow COSN (OH)6Nano cube;

[0087](2) Take 0.4g CoSN (OH)6Diered in 50 ml of deionized water, then 2 g pdda, 0.3 6 g of Tris and 0.16 g of sodium chloride were added, stirred for 120min, then wash 3 times with deionized water to remove excess PDDA, and will carry positively charged COSN (OH)6The nanotum was added to a graphene solution of 20 ml of concentration of 3 mg / ml, stirred for 10 min, and the dry and dry, cosn (OH)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com