Nano noble metal catalyst for automobile exhaust purification and preparation method thereof

A precious metal catalyst, automobile exhaust technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of low utilization rate of precious metal, low catalyst stability, Problems such as low precious metal content, to achieve economic cost savings, high oxygen storage capacity, and low precious metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention also discloses a method for preparing a nano-precious metal catalyst for automobile exhaust purification, comprising the following steps:

[0021] a. Preparation of coating slurry for different nano-noble metal oxygen storage materials: mix appropriate amount of water, activated alumina, and cerium-zirconium oxide, add rare earth additives and dispersants, stir well, add noble metal salt solution, and adjust the pH value to 3 ~4, finally add the binder, stir for 6~12 hours, and ball mill for 30~60 minutes to obtain the coating solution; in this way, the coating solution of each layer of coating is prepared by adding different precious metal salt solutions; prepared by adding different precious metal salt solutions The coating slurry containing different noble metals is used to coat the slurry on the honeycomb ceramics to form oxygen storage material coatings containing different kinds of nanometer noble metals. The purpose of ball milling is to obtain coat...

Embodiment 1

[0026] (1) Preparation of Pd layer slurry: After dissolving 12g of praseodymium nitrate and 0.6g of polyvinyl alcohol in 180g of water, add 73g of cerium-zirconium solid solution A and 31g of alumina to mix, wherein the component of cerium-zirconium solid solution A is 60% CeO 2 -40%ZrO 2 , the alumina component is 4% La 2 o 3 -96% Al 2 o 3 After stirring evenly, take 6g of palladium nitrate solution with a concentration of 17.91%, slowly drop it into the slurry, adjust the pH to 3, add a binder, stir for 6h, and ball mill for 30min to prepare the Pd layer slurry.

[0027] (2) Preparation of Rh layer slurry: After dissolving 9g of praseodymium nitrate and 0.5g of polyvinyl alcohol in 150g of water, add 50g of cerium-zirconium solid solution B and 34g of alumina and mix, wherein the component of cerium-zirconium solid solution B is 30% CeO 2 -70%ZrO 2 , the alumina composition is the same as the Pd layer is 4% La 2 o 3 -96% Al 2 o 3 After stirring evenly, take 1.3g of ...

Embodiment 2

[0033] (1) Preparation of Pd layer slurry: after dissolving 6g praseodymium nitrate, 6g cerium nitrate and 0.6g polyvinyl alcohol in 180g water, add 63g cerium-zirconium solid solution A and 42g alumina to mix, after stirring evenly, get 6g concentration to be 17.91% palladium nitrate solution was slowly added dropwise to the slurry, the pH was adjusted to 4, a binder was added, after stirring for 6 hours, the Pd layer slurry was prepared by ball milling for 30 minutes.

[0034] (2) Preparation of Rh layer slurry: After dissolving 5g of lanthanum nitrate, 6g of yttrium nitrate and 0.5g of polyvinyl alcohol in 150g of water, add 59g of cerium-zirconium solid solution B and 25g of alumina to mix, stir well, and take 1.3g of concentration Slowly add a 9.47% rhodium nitrate solution into the slurry, adjust the pH to 3-4, add a binder, stir for 6 hours, and ball mill for 30 minutes to prepare the Rh layer slurry.

[0035] (3) coating and roasting: with embodiment 1

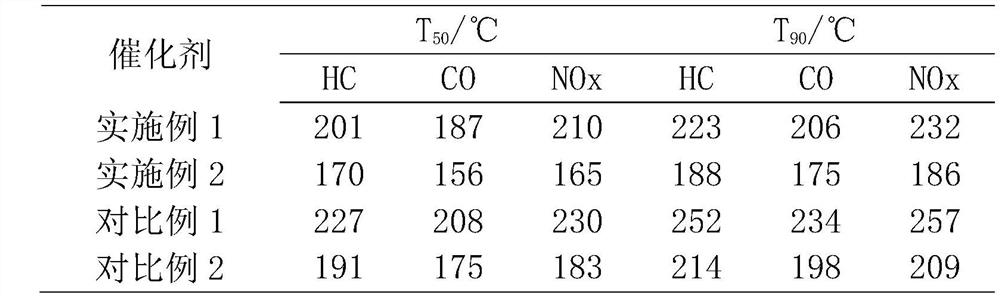

[0036] Activi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com