Batch production method of graphene film and graphene film prepared by method

A graphene film, batch technology, applied in the direction of graphene, chemical instruments and methods, layered products, etc., can solve the problems of poor stability, difficulty in graphene oxide self-assembly, high cost, and large energy consumption of graphite oxide. Achieve the effects of reduced baking time, low cost, and strong defoaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] The present embodiment provides a batch production method of graphene film, and described batch production method specifically comprises the following steps:

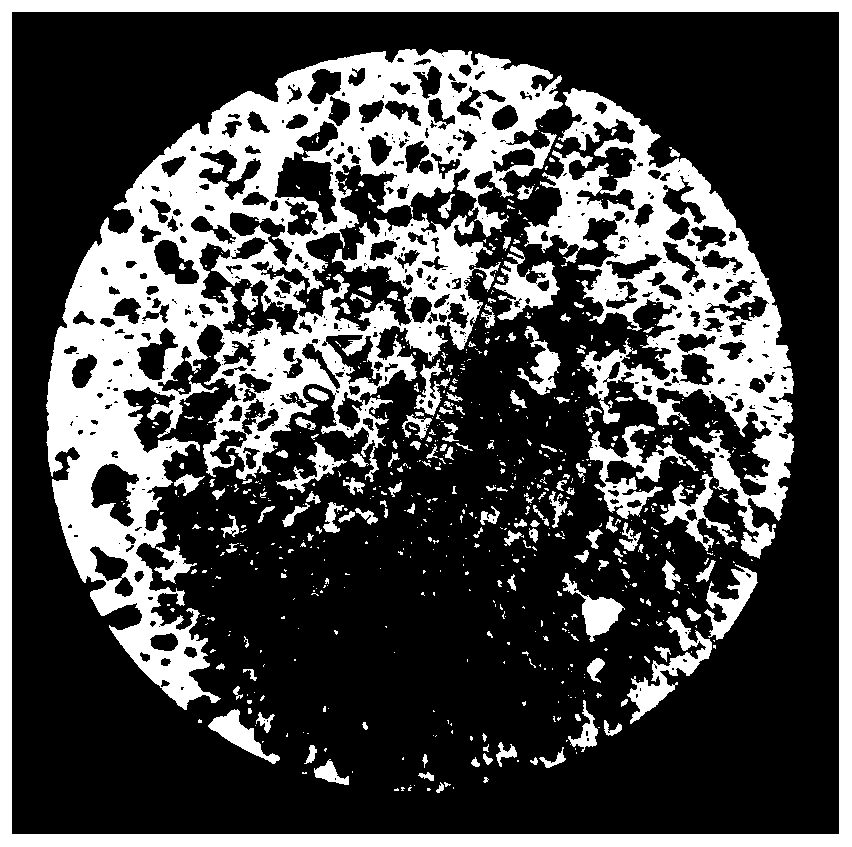

[0097] (1) the graphite oxide filter cake of solid content 45% is preliminarily dispersed in deionized water to obtain graphite oxide solution (such as figure 1 shown), then add a certain amount of ammonia solution to adjust the pH value of the graphite oxide solution to 7.2, and the graphite oxide particle size in the graphite oxide solution is 120 μm;

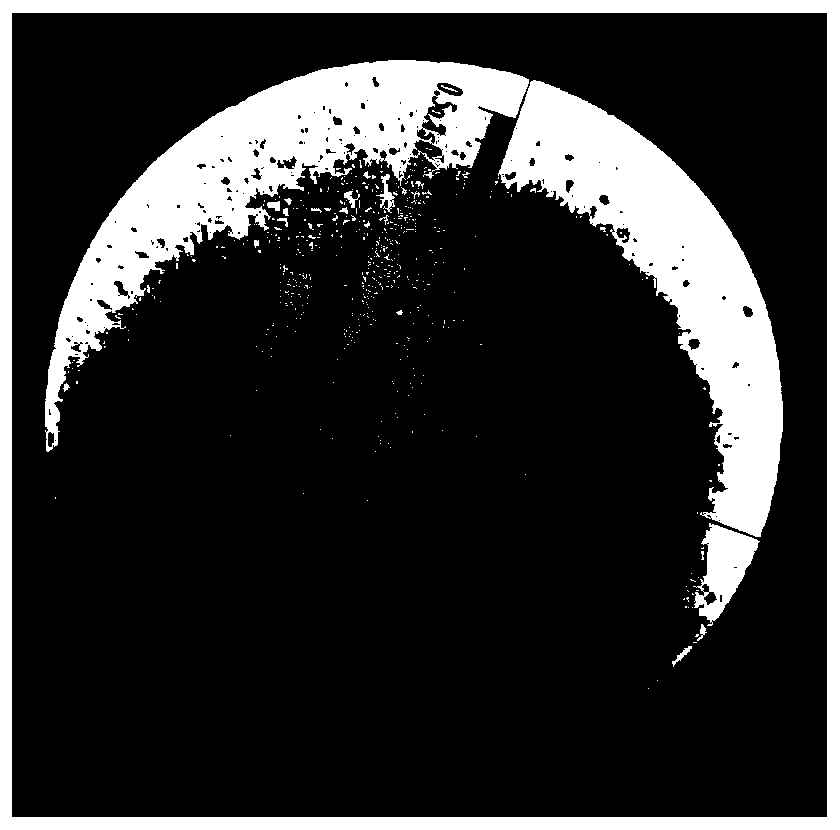

[0098] (2) the graphite oxide solution in the step (1) is pre-dispersed using a double planetary mixer, and the micrograph of the graphite oxide solution after the pre-dispersion is as follows figure 2 As shown, the graphite oxide flakes are uniformly dispersed in the solvent by means of stirring and shear dispersion, the solid content of graphite oxide in the pre-dispersed graphite oxide solution is 6.4wt%, and the stirring speed of the double planetary mixer ...

Embodiment 2

[0111] The present embodiment provides a batch production method of graphene film, and described batch production method specifically comprises the following steps:

[0112] (1) Preliminarily disperse the graphite oxide filter cake with a solid content of 40% in deionized water to obtain a graphite oxide solution, then add a certain amount of ammonia solution to adjust the pH value of the graphite oxide solution to 6, and the graphite oxide particles in the graphite oxide solution Diameter 80μm;

[0113] (2) The graphite oxide solution in step (1) is pre-dispersed using a double planetary mixer, and the graphite oxide flakes are uniformly dispersed in the solvent by a combination of stirring and shear dispersion, and the graphite oxide solution after the pre-dispersion The solid content of graphite oxide is 4.2wt%, the stirring speed of the double planetary mixer is 40rpm, and the dispersion speed is 1000rpm; the viscosity of graphite oxide solution after predispersion is 2500...

Embodiment 3

[0125] The present embodiment provides a batch production method of graphene film, and described batch production method specifically comprises the following steps:

[0126] (1) Preliminarily disperse the graphite oxide filter cake with a solid content of 42% in deionized water to obtain a graphite oxide solution, then add a certain amount of sodium hydroxide solution to adjust the pH value of the graphite oxide solution to 6.3, the oxidation in the graphite oxide solution Graphite particle size 100μm;

[0127] (2) The graphite oxide solution in step (1) is pre-dispersed using a double planetary mixer, and the graphite oxide flakes are uniformly dispersed in the solvent by a combination of stirring and shear dispersion, and the graphite oxide solution after the pre-dispersion The graphite oxide solid content is 4.5wt%, the stirring speed of the double planetary mixer is 45rpm, and the dispersion speed is 1300rpm; the viscosity of the graphite oxide solution after predispersion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal diffusivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com