Longitudinal high-thermal-conductivity gasket, preparation method and application

A high thermal conductivity, vertical technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as the difficulty in controlling the orientation of anisotropic fillers, the inability to effectively remove air bubbles, and affecting the heat conduction effect of products. , to achieve the effect of not easy to stratify, exclude air bubbles, and high degree of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

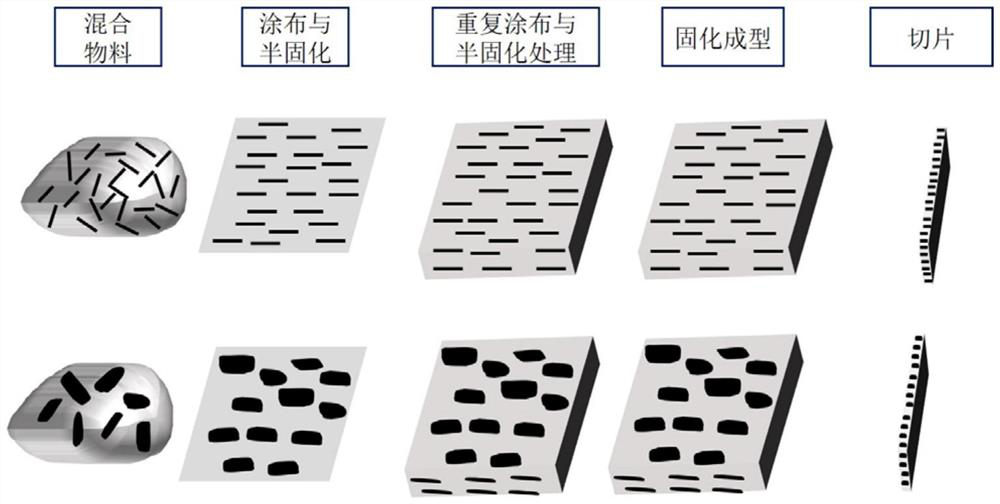

[0079] figure 1 is a schematic diagram of the preparation method of the longitudinal high thermal conductivity gasket of the present invention, as figure 1 Shown, described preparation method comprises:

[0080] Mixing materials, mixing the materials evenly to obtain a mixed material, the materials include a binder, an anisotropic thermally conductive filler and an optional isotropic thermally conductive filler;

[0081] Coating and semi-curing, applying the mixed material to the surface of the base material, obtaining a coating on the surface of the base material, and treating (heating or / and standing) the coating to a semi-cured (semi-vulcanized) state , obtain the coating of semi-cured (semi-vulcanized) state;

[0082] Repeating the coating and semi-curing treatment, coating the mixed material on the coating in the semi-cured state again, repeating the semi-curing treatment and coating several times until the thickness of the coating reaches the thickness requirement;

...

Embodiment 1

[0088] In this embodiment, binder: polydimethylcyclosiloxane, content 40wt.%,

[0089] Anisotropic thermal conductive filler: carbon fiber, content 60wt.%, length 300μm, diameter 15μm,

[0090] Coating rate: 1.5m / min,

[0091] The thickness of each coating is 1.5mm and the width is 200mm.

[0092] Heating: temperature 80°C, time 3min,

[0093] Vulcanization: temperature 150°C, time 30min,

[0094] After testing, the applied thermal resistance of the vertical high thermal conductivity gasket obtained in this embodiment is 1.42W cm 2 / K, thermal conductivity 17.75W / (m K), compression rebound rate 92%.

Embodiment 2

[0096] In this embodiment, binder: polydimethylsiloxane, content 30wt.%,

[0097] Anisotropic thermal conductive filler: carbon fiber, content 40wt.%, length 100μm, diameter 10μm,

[0098] Isotropic thermally conductive filler: alumina, content 30wt.%, particle size 100μm,

[0099] Coating rate: 0.5m / min,

[0100] The thickness of each coating is 0.5mm, and the width is 100mm.

[0101] Heating: temperature 60°C, time 5min,

[0102] Vulcanization: temperature 100°C, time 90min,

[0103] After testing, the applied thermal resistance of the vertical high thermal conductivity gasket obtained in this embodiment is 2.03W·cm 2 / K, thermal conductivity 11.34W / (m K), compression rebound rate 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com