Manufacture device and manufacture method for height limit type preformed soldering terminals

A technology for solder preforms and manufacturing devices, applied in the direction of manufacturing tools, welding media, welding equipment, etc., can solve the problems of low welding strength, no public reports, low production efficiency, etc., and achieve accurate, stable and continuous product dimensions High degree of effect with low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

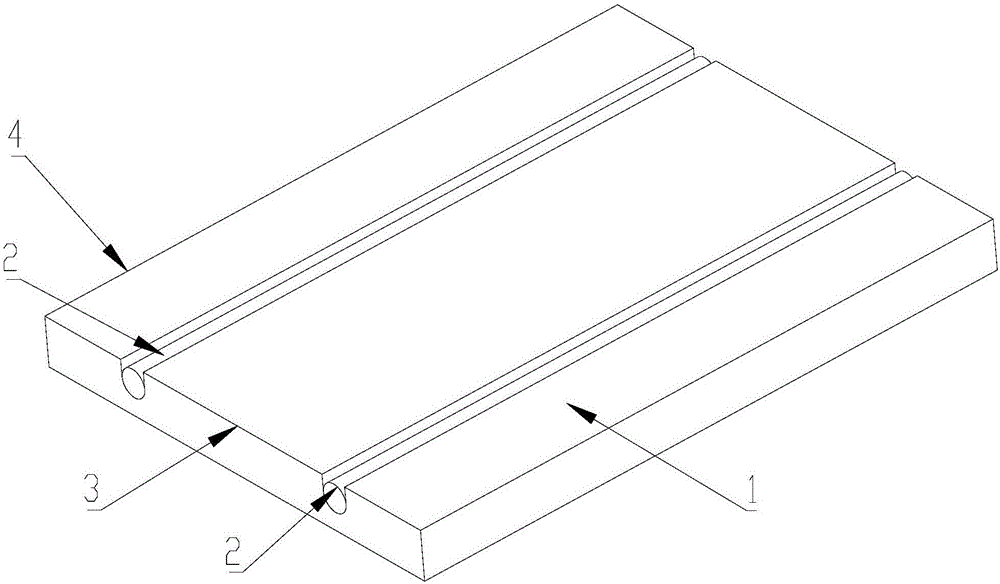

[0044] Such as figure 1 As shown, the height-limited solder preform includes: solder base 1, wire 2;

[0045] The solder lug base 1 is a cuboid, and the surface of the solder lug base 1 is provided with two grooves parallel to the long side 4, the cross section of the groove is circular, the metal wire is copper wire, and the metal wire 2 has the same size as the groove and can be embedded in the groove to fix.

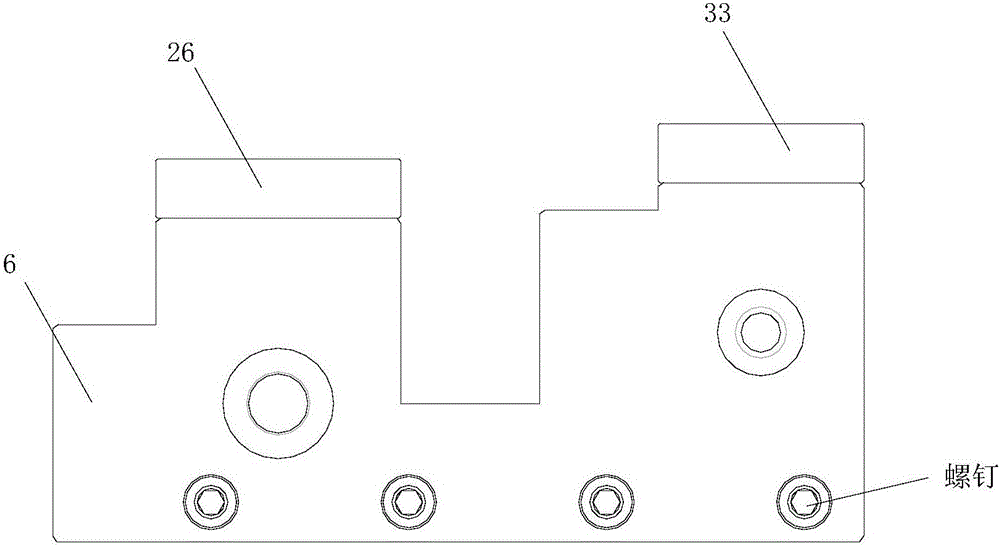

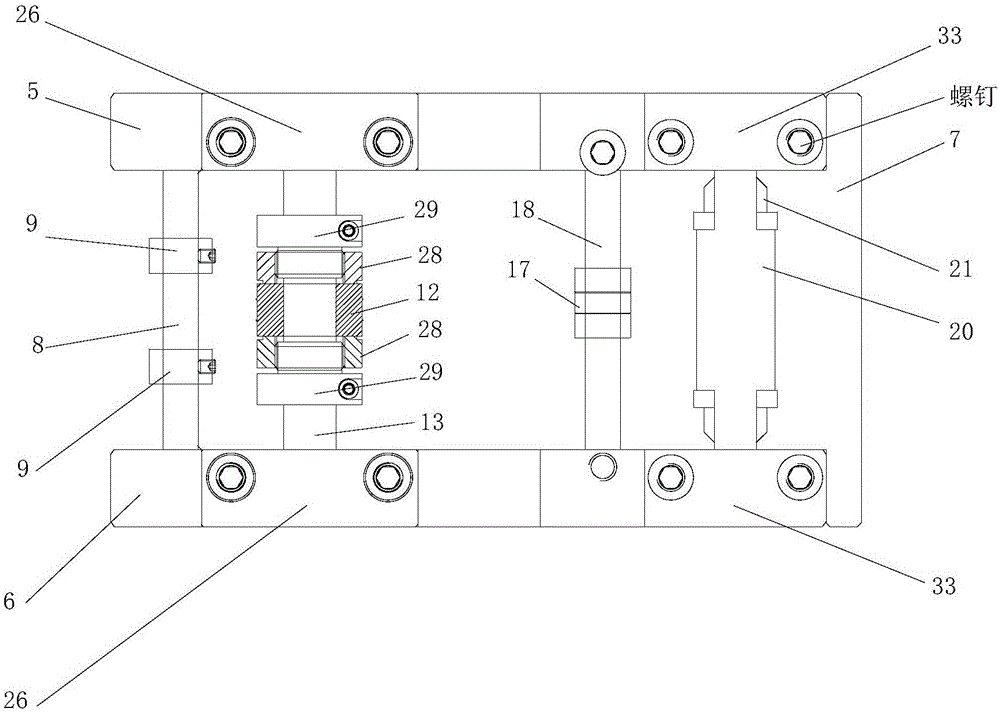

[0046] Such as Figure 2-13 As shown, a manufacturing device for a height-limited solder preform includes: a bracket, a guiding mechanism, a slotting mechanism, a wire guiding mechanism, and a wire planting mechanism, and the guiding mechanism, a slotting mechanism, a wire guiding mechanism, and a wire planting mechanism set on the bracket in turn;

[0047] Described bracket comprises rear side plate 5, front side plate 6, base plate 7, rear side plate 5 and front side plate 6 are mutually symmetrical parts, rear side plate 5 and front side plate 6 are arranged sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com