Production process and equipment for round bamboo expansion flat plate

A production process, the technology of round bamboo, applied in the production process of round bamboo flat plate and the field of unfolding, setting and thickness setting machine, can solve the problems of low degree of automation and continuity, affecting economic benefits, increasing fractures, etc., and achieves the solution of storage deterioration and dry, simple production process, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Saw the original bamboo and remove the outer and inner nodes to make it into a bamboo tube, and dig grooves on the bamboo yellow on the inner surface of the bamboo tube, and then put the bamboo tube into an aqueous solution of sodium pyrosulfite with a mass fraction of 0.55% for storage.

[0034] The thickness of the groove does not exceed the thickness of the bamboo yellow, and the direction of the groove is vertical or at a certain angle to the bamboo tube.

[0035] (2) Slit the bamboo tubes stored in the sodium pyrosulfite aqueous solution and soften at high temperature, then unfold, shape and planer to determine the thickness to obtain a round bamboo unfolded plate with basically no bamboo green and bamboo yellow on the surface, uniform thickness and no deformation, and become Standardized production of high-quality bamboo panels.

[0036] The unfolding, setting and planing are carried out in an all-in-one machine for unfolding, setting and thickness setting.

...

Embodiment 2

[0043] (1) Saw off the fresh raw bamboo and remove the outer and inner nodes to make it into a bamboo tube, and dig grooves on the bamboo yellow on the inner surface of the bamboo tube. The bamboo tubes are vertical or at an angle.

[0044] (2) Open the grooved fresh bamboo tube and soften it at high temperature, then unfold, shape and planer to determine the thickness to obtain a round bamboo unfolded flat plate with basically no bamboo green and bamboo yellow on the surface, uniform thickness and no deformation, which has become a standardized Production of high-quality bamboo panels.

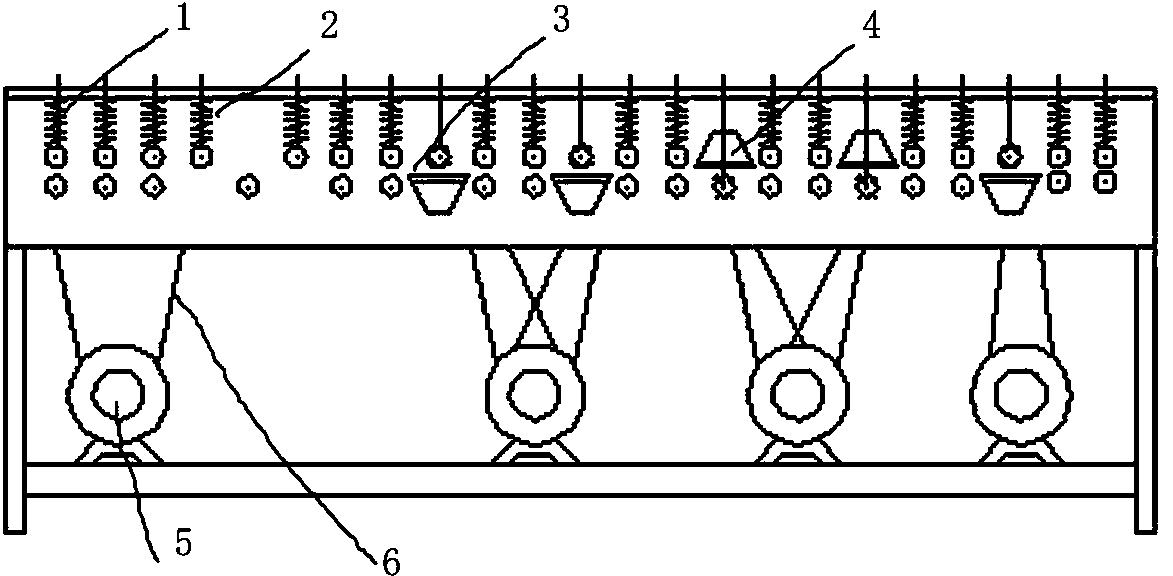

[0045] In order to improve work efficiency, save production cost, and also make the qualified rate of the obtained bamboo flat plate higher, and the quality is better, the present invention also provides a kind of as figure 1 The shown integrated machine for unfolding, shaping and thickness-setting of round bamboo includes an unfolding roller 1, a shaping cylinder 2 and a thickness-setting p...

Embodiment 3

[0051] (1) Saw the original bamboo and remove the outer and inner nodes to make it into a bamboo tube, and dig a groove on the bamboo yellow on the inner surface of the bamboo tube, and then put the bamboo tube into an aqueous solution of sodium pyrosulfite with a mass fraction of 1.42% for storage.

[0052] The thickness of the groove does not exceed the thickness of the bamboo yellow, and the direction of the groove is vertical or at a certain angle to the bamboo tube.

[0053] (2) Slit the bamboo tubes stored in the sodium pyrosulfite aqueous solution and soften at high temperature, then unfold, shape and planer to determine the thickness to obtain a round bamboo unfolded plate with basically no bamboo green and bamboo yellow on the surface, uniform thickness and no deformation, and become Standardized production of high-quality bamboo panels.

[0054] The unfolding, setting and planing are carried out in an all-in-one machine for unfolding, setting and thickness setting. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com