Preparation method of energy-saving electronic-grade carbonic ester

An electronic grade carbonate technology, which is applied in the preparation of electronic grade carbonate, electronic grade ethyl methyl carbonate and diethyl carbonate, can solve the problems of high energy consumption and low purity, and achieve high yield , high degree of continuity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

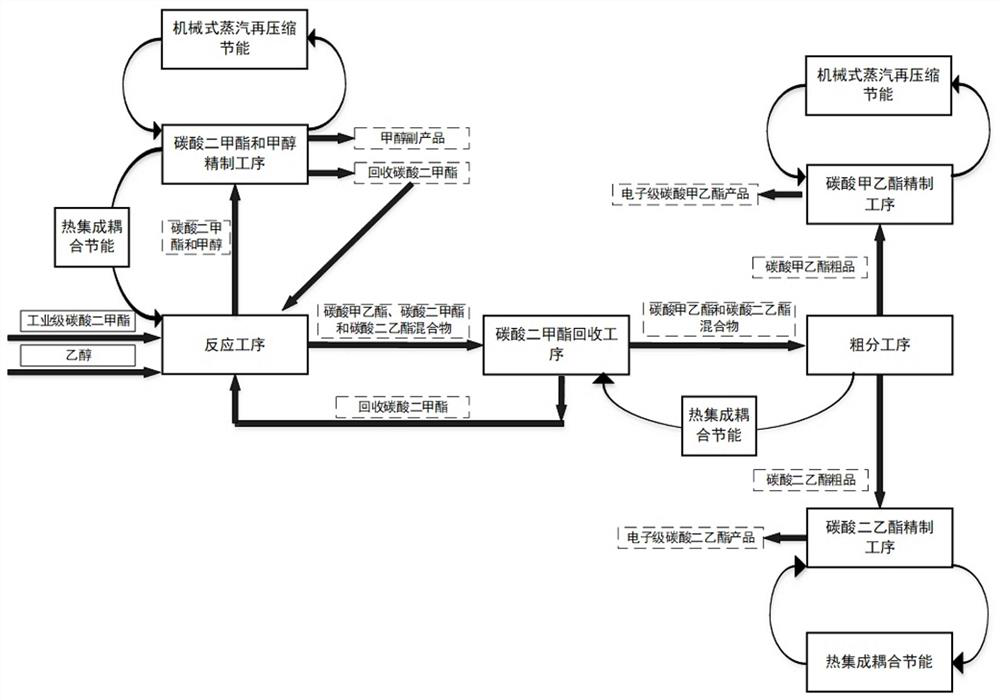

[0085] Such as figure 1 Shown, a kind of energy-saving preparation method of electronic grade carbonate comprises reaction procedure, dimethyl carbonate recovery procedure, coarse fractionation procedure, ethyl methyl carbonate refining procedure, diethyl carbonate refining procedure and dimethyl carbonate and methyl alcohol Refining process;

[0086] Industrial-grade dimethyl carbonate and absolute ethanol enter the described reaction process after being preheated by a preheater, and esterification takes place under the action of a catalyst to obtain a compound containing dimethyl carbonate, ethyl methyl carbonate and diethyl carbonate. Esters, and dimethyl carbonate and methanol azeotrope;

[0087] The mixture containing dimethyl carbonate, ethyl methyl carbonate and diethyl carbonate enters the described dimethyl carbonate recovery process to reclaim unreacted dimethyl carbonate;

[0088] The mixture of ethyl methyl carbonate and diethyl carbonate enters the described coa...

Embodiment 2

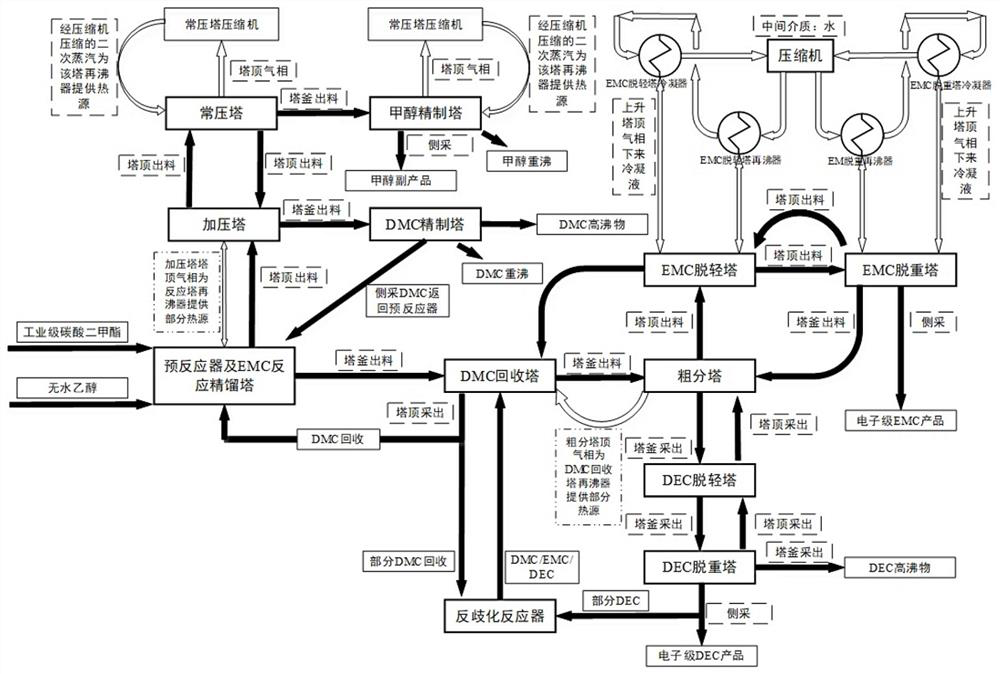

[0093] Such as figure 2 As shown, on the basis of Embodiment 1, this embodiment further describes the equipment in each process in detail.

[0094] Described reaction procedure comprises prereactor 1 and EMC reactive rectification column 2;

[0095] Described dimethyl carbonate recovery operation comprises DMC recovery tower 3;

[0096] Described rough fractionation operation comprises rough fractionation column 5;

[0097]Described ethyl methyl carbonate refining process comprises EMC delightening tower 6 and EMC deweighting tower 7;

[0098] Described diethyl carbonate refining process comprises DEC delightening tower 8 and DEC deweighting tower 9;

[0099] Dimethyl carbonate and methanol refining process comprise pressurized tower 10, atmospheric tower 11, methanol refining tower 12 and DMC refining tower 13;

[0100] Industrial-grade dimethyl carbonate and absolute ethanol enter the described prereactor 1 to react after being preheated by the preheater, and the reacti...

Embodiment 3

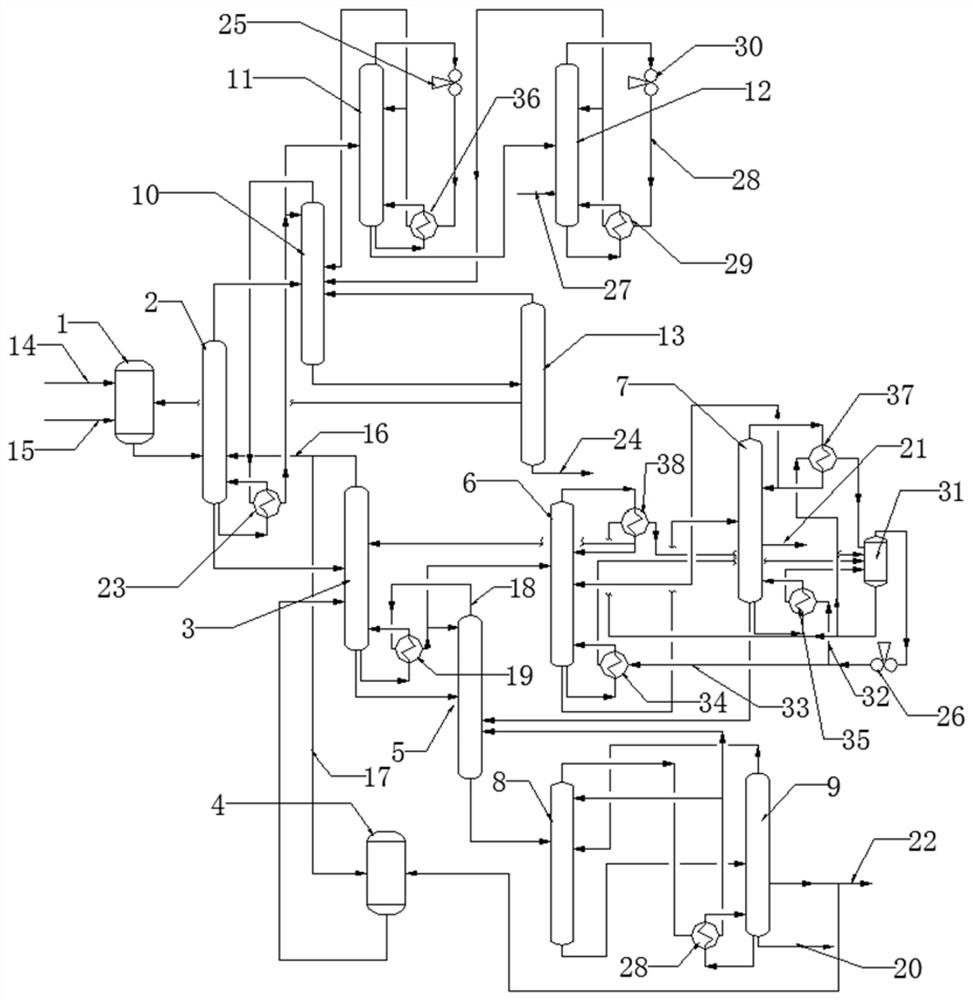

[0111] An energy-saving electronic grade carbonate preparation system, such as image 3 As shown, it includes a pre-reactor 1, an EMC reactive distillation tower 2, a DMC recovery tower 3, an anti-disproportionation reactor 4, a crude fractionation tower 5, an EMC de-light tower 6, an EMC de-weight tower 7, a DEC de-light tower 8, DEC weight removal tower 9, pressurization tower 10, atmospheric tower 11, methanol refining tower 12 and DMC refining tower 13;

[0112] The prereactor 1 is connected with an industrial-grade dimethyl carbonate feed line 14 and an ethanol feed line 15, and the bottom outlet of the prereactor 1 is connected with the EMC reaction rectification tower 2 of the pipeline through the The middle and lower part feed ports are connected, and the catalytic packing containing solid catalyst is arranged in the described EMC reactive rectification tower 2;

[0113] The tower kettle outlet of described EMC reactive distillation tower 2 is connected with the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com