Elastic cable and preparation method thereof

A cable, elastic and conductive technology, applied in the direction of cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., to achieve the effect of high degree of continuity, good molding, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

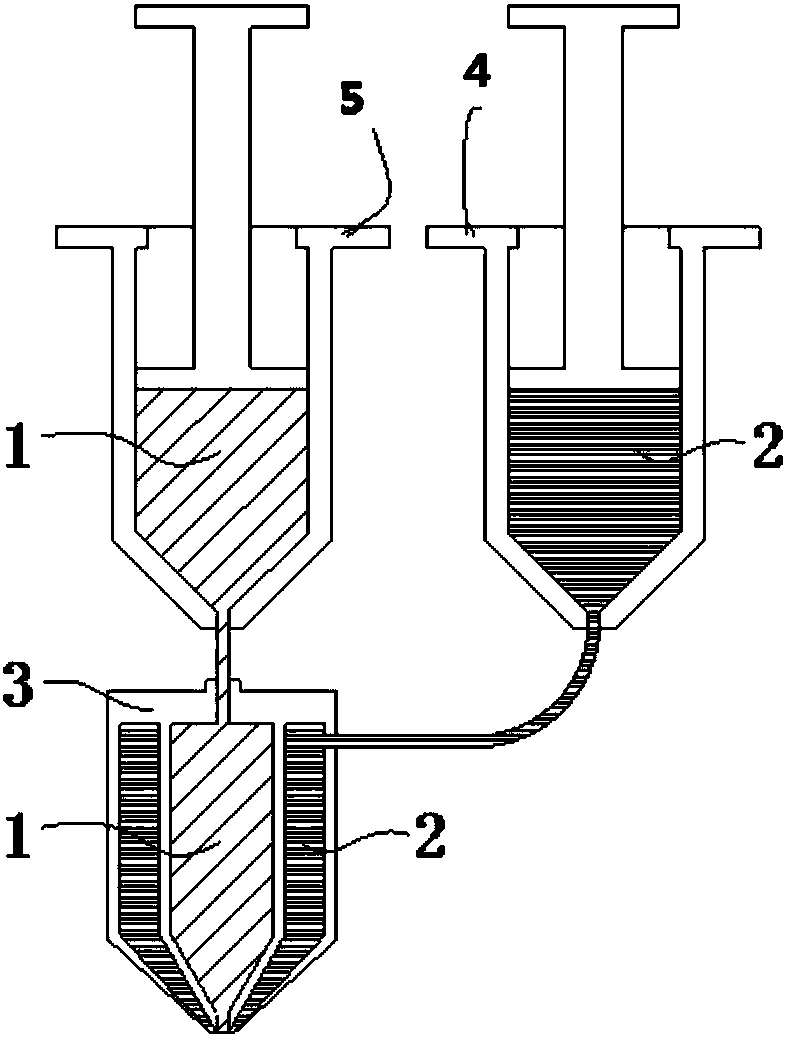

[0028] Such as figure 1 Shown, a kind of preparation method of elastic cable wire, described preparation method comprises the steps:

[0029] (1) Load the eutectic alloy Ga75.5-In24.5 gallium-indium alloy (liquid at -10 to 40°C) into the first extrusion system 5, and load Dow Corning SE1700 silicone rubber into the second extrusion system 4 ;

[0030] (2) Arrange the first extruding system 5, the second extruding system 4 and the nozzle 3 in parallel, and connect the first extruding system 5 and the second extruding system 4 to the inner core and the outer core of the nozzle 3 respectively through the conduit. The cavity is connected; the inner core inner diameter of the nozzle is 0.21 mm, the inner core outer diameter is 0.4 mm, and the outer shell inner diameter is 13 mm;

[0031] (3) Set the extrusion air pressure of the first extrusion system 5 to 0.1psi, the extrusion air pressure of the second extrusion system 4 to 70psi, and the nozzle 3 to print the cable on the prin...

Embodiment 2

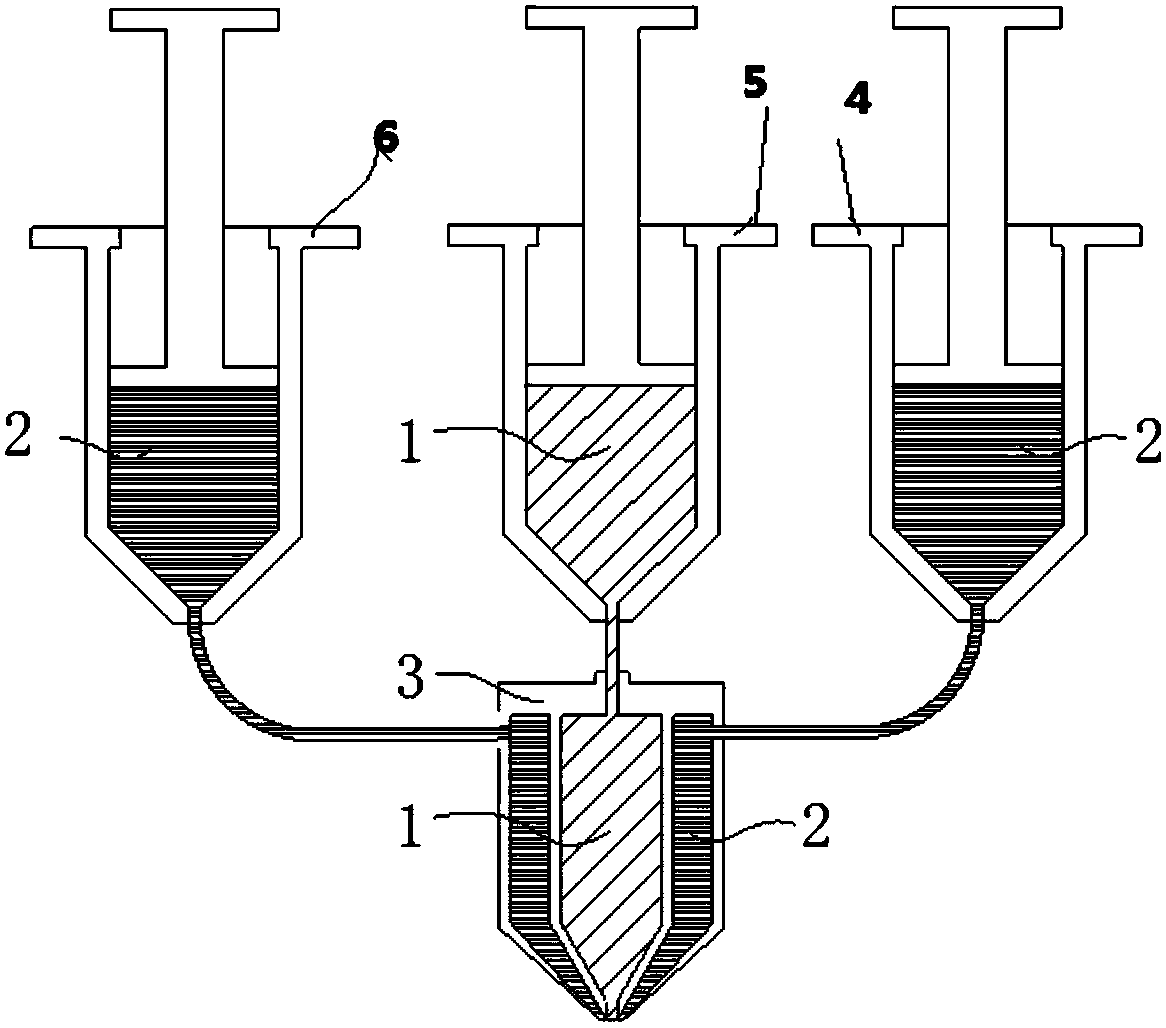

[0036] A method for preparing an elastic cable, the method comprising the steps of:

[0037] (1) load conductive carbon paste material in the first extrusion system 5, and load Dow Corning Sylgard184 silicone rubber in the second extrusion system 4;

[0038] (2) Arrange the first extruding system 5, the second extruding system 4 and the nozzle 3 in parallel, and connect the first extruding system 5 and the second extruding system 4 to the inner core and the outer core of the nozzle 3 respectively through the conduit. The cavity is connected; the inner core inner diameter of the nozzle is 0.21 mm, the inner core outer diameter is 0.4 mm, and the outer shell inner diameter is 13 mm;

[0039] (3) The extrusion air pressure of the first extrusion system 5 is set to 26psi, the extrusion air pressure of the second extrusion system 4 is 40psi, and the nozzle 3 prints the cable on the printing substrate at a printing speed of 4mm / s;

[0040] (4) adopting 120° C. heating and heat-curi...

Embodiment 3

[0044] A method for preparing an elastic cable, the method comprising the steps of:

[0045] (1) Load conductive polymer PEDOT / PSS (poly 3,4-ethylenedioxythiophene / polystyrene sulfonate) solution in the first extrusion system 5, and load Dow Corning 3 in the second extrusion system 4 -6371UV silica gel;

[0046] (2) Arrange the first extruding system 5, the second extruding system 4 and the nozzle 3 in parallel, and connect the first extruding system 5 and the second extruding system 4 to the inner core and the outer core of the nozzle 3 respectively through the conduit. The cavity is connected; the inner core inner diameter of the nozzle is 0.21 mm, the inner core outer diameter is 0.4 mm, and the outer shell inner diameter is 13 mm;

[0047](3) Set the extrusion air pressure of the first extrusion system 5 to 20psi, the extrusion air pressure of the second extrusion system 4 to 40psi, and the nozzle 3 prints the cable on the printing substrate at a printing speed of 5mm / s; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com