Automatic loading and unloading device of large plasma cutting machine

A plasma cutting machine, automatic loading and unloading technology, applied in the direction of plasma welding equipment, auxiliary devices, welding/cutting auxiliary equipment, etc., can solve the problems of low efficiency of manual feeding, high labor intensity, poor safety, etc., to improve operation safety. performance, reduce production and management costs, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments; the given embodiments are only used to explain the present invention, and are not intended to limit the scope of the present invention.

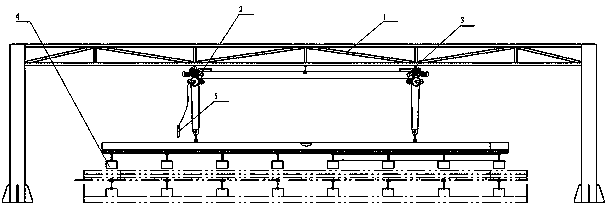

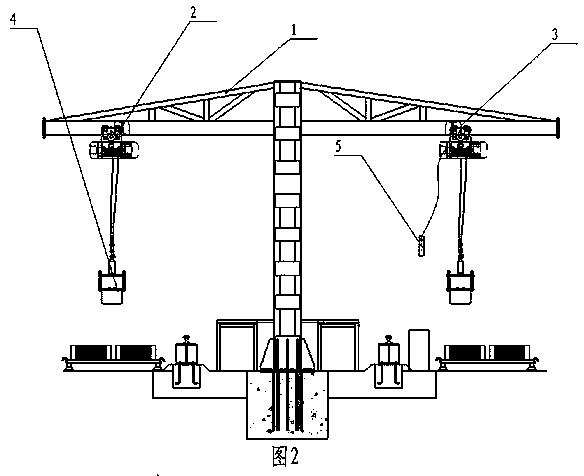

[0014] Example 1, see Figure 1, according to the design requirements, the truss 1 is manufactured. The truss 1 is made of a combination of rectangular tube and channel steel, which meets the mechanical requirements, has good stability, high rigidity, and strong bending resistance. The column is made of channel steel and steel plate. Combined welding, strong load-bearing capacity and good deformation resistance; two walking electric hoists with lifting function constitute the feeding and conveying mechanism 2, which controls the horizontal and up-and-down movement of the electromagnetic hoist 4, which is convenient for stacking the material rack The sheet is lifted and transported from the loading prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com