Hot-melt extrusion composition containing traditional Chinese medicine volatile oil and preparation method and pharmaceutical preparation thereof

A technology of hot-melt extrusion and pharmaceutical preparations, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, and medical preparations with non-active ingredients. Loss and other problems, to achieve the effect of convenient carrying and transportation, improve long-term stability, and reduce irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of hot-melt extrusion composition containing patchouli oil, further prepared pharmaceutical preparations and property testing Certainly

[0034] 1.1 Preparation of hot melt extrusion composition containing patchouli oil

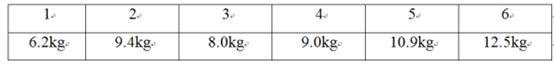

[0035] The components contained in the patchouli oil-containing hot melt extrusion composition (samples 1 to 11) and the content of each component are shown in Table 1 below:

[0036] Table 1

[0037]

[0038] The preparation process of samples 1 and 2: weigh 5g copovidone and 2g colloidal silicon dioxide, mix well, then slowly add patchouli oil, make the material mix evenly, add the remaining amount of copovidone, continue to mix evenly, add the remaining Measure colloidal silicon dioxide, mix well, put the mixture into the hot melt extruder, and carry out hot melt extrusion. Hot melt extrusion operating temperature: 80~135℃, screw speed 30~100rpm.

[0039] Sample 3 preparation process: Weigh 5g copovidone and 2g collo...

Embodiment 2

[0094] Example 2 Preparation of hot-melt extrusion composition containing Artemisia argyi oil, further prepared pharmaceutical preparations and property determination

[0095] 2.1 Preparation of hot-melt extrusion composition containing mugwort oil

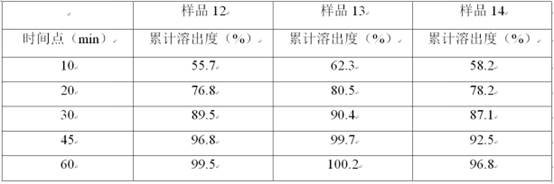

[0096] Please refer to the following table 9 for the components contained in the hot melt extrusion composition containing mugwort oil (sample 12-14) and the content of each component:

[0097] Table 9

[0098]

[0099] The preparation process of sample 12 is as follows: Weigh 10 g of copovidone and 1 g of stearic acid, then slowly add mugwort oil to mix the materials evenly, add colloidal silicon dioxide, and continue to mix evenly. The mixture is fed into a hot-melt extruder for hot-melt extrusion. Operating temperature: 100-135°C, screw speed 50-100rpm.

[0100] Samples 13-14 were prepared using the same preparation process as sample 12, except that the step of adding stearic acid was replaced by adding polyethylene g...

Embodiment 3

[0117] Embodiment 3 Preparation and Performance Measurement of Hot-melt Extrusion Composition Containing Eucalyptus Oil

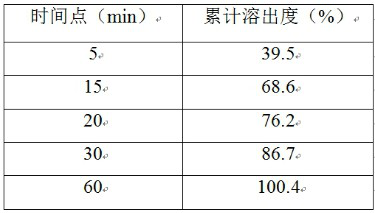

[0118] The components contained in the hot melt extrusion composition containing eucalyptus oil and the content of each component are shown in the following table 12:

[0119] Table 12

[0120]

[0121] The preparation process is as follows: Weigh 3g of polyethylene caprolactam-polyvinyl acetate-polyethylene glycol graft copolymer, 7g of copovidone, 1g of stearic acid, 1g of polyethylene glycol-15 hydroxystearate, and then slowly Add eucalyptus oil to mix the materials evenly, add 3g of colloidal silicon dioxide, and continue to mix evenly. Then put the uniformly mixed particles into the hot-melt extruder for hot-melt extrusion. Operating temperature: 50-135°C, screw speed 30-100rpm.

[0122] The resulting extruded strips were transparent to white. Take an appropriate amount of pulverized particles and put them into a beaker, and stir slowly for 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com