Waste tire thermal cracking device

A waste tire and pyrolysis technology, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and the treatment of hydrocarbon oil, etc., can solve the problems of energy waste, high cost, environmental pollution, etc., and achieve the effect of solving pollution problems and environmental protection emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

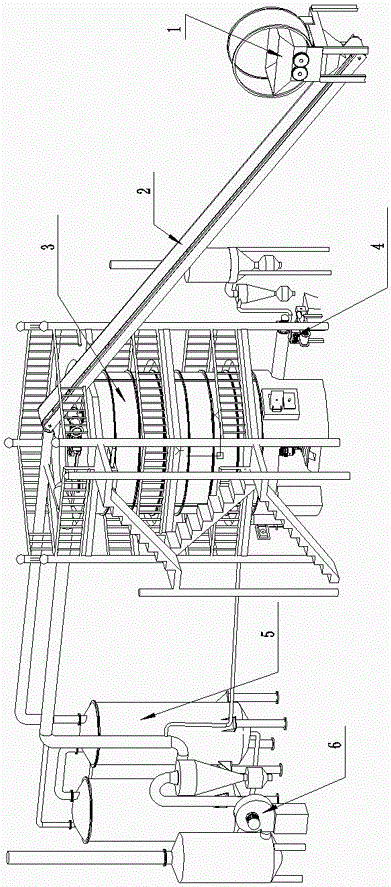

[0028] A waste tire pyrolysis device, comprising a waste tire crushing device 1, a pyrolysis furnace 3, an oil gas recovery system 5, a flue gas discharge system 6, and a solid material recovery system 4,

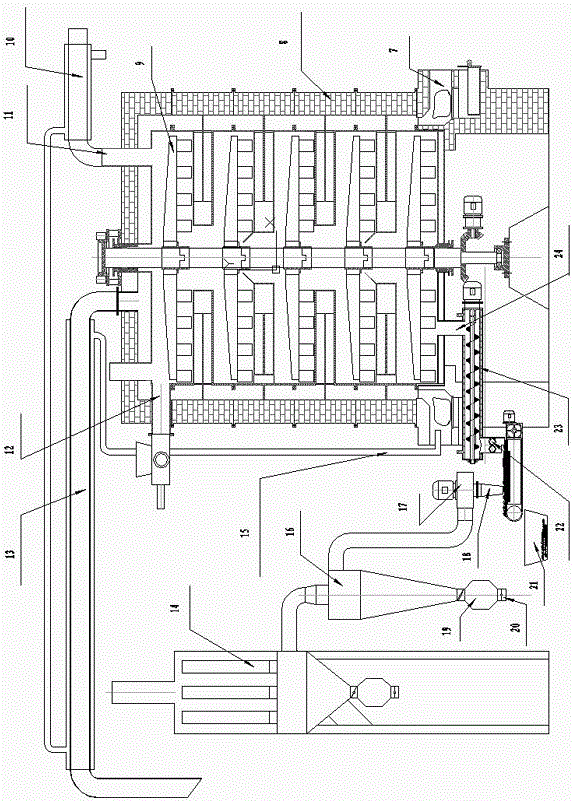

[0029] The thermal cracking furnace is provided with a furnace body, the furnace body is provided with a vertically arranged furnace, the furnace body is provided with an insulating shell 8, the upper part of the furnace body is provided with a feed inlet 12, a flue gas discharge port and an oil gas outlet 11, and the furnace body The lower part is provided with a solid material outlet 24 connected to the solid material recovery system; the smoke exhaust port is connected to the smoke exhaust system through the smoke exhaust pipe 10, and the oil gas outlet is connected to the oil gas recovery system through the oil gas exhaust pipe 13;

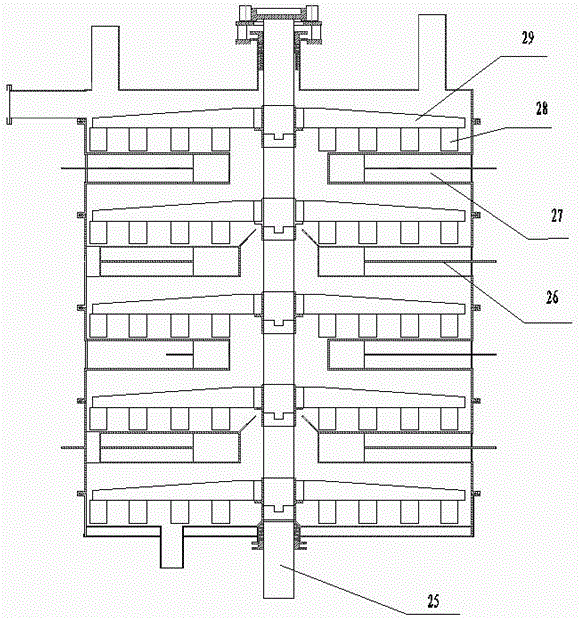

[0030] There is a closed hearth body 9 inside the furnace, the upper end of the hearth body is provided with an inner feed pipe connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com