Light stone-imitating particulate matter and water-based stone-imitating coating prepared by adopting same

A kind of particle, imitating stone technology, applied in coating and other directions, to achieve the effect of realistic imitation stone, environmental protection and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

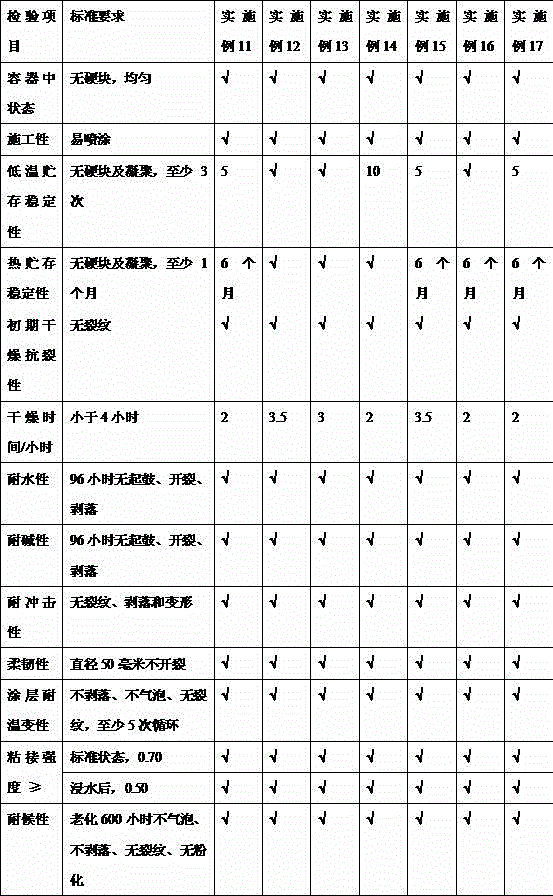

Examples

Embodiment 1

[0020] In Example 1, waste tire rubber particles are directly used as black imitation stone particles.

Embodiment 2

[0021] The processing methods of Examples 2 and 3 are as follows: firstly, the plastic paint and the dispersant are mixed evenly, then pearlescent pigments, gold powder or silver powder are added, and the mixture is evenly stirred. Then, centrifuge to remove excess plastic paint. After drying to form a film, the imitation stone particles of the desired color can be obtained. Embodiment 2 obtains light imitation stone particles with a small amount of pearl luster. Embodiment 3 obtains light imitation stone particles with a small amount of silver and gold.

[0022] The processing method of embodiment 4 and 5 is, select the plastic paint of certain color according to required color, then mix solidified epoxy resin or carbonate waste granule with plastic paint, stir, centrifuge and remove excessive plastic paint. After drying to form a film, the imitation stone particles of the desired color can be obtained.

[0023] Examples 6-10 of light imitation stone particle gradation

...

Embodiment 11- Embodiment 15

[0029] Prepare the following raw materials:

[0030] The lightweight imitation stone particles are self-made in the invention.

[0031] Emulsion: styrene-acrylic emulsion, silicon-acrylic emulsion, vinegar-acrylic emulsion, elastic emulsion, Jiangsu Zishi Chemical Technology Co., Ltd.; pure acrylic emulsion, silicon-modified styrene-acrylic / pure acrylic emulsion, water-based polyurethane dispersion, Shandong Future Chemical Technology Co., Ltd. .

[0032] Titanium dioxide: titanium dioxide, Langfang Rainbow Pigment Products Co., Ltd.

[0033] Inorganic filler: Silica powder, Qingyuan Mineral Products Processing Plant, Lingshou County; kaolin, talcum powder, calcium carbonate, wollastonite powder, Beijing Liguoweiye Superfine Powder Co., Ltd.; bentonite, Anyang Yihe Bentonite Co., Ltd. ; Mica powder, Chuzhou Gree Mining Co., Ltd.; barium sulfate, Yangcheng Tianhai Barium Salt Chemical Plant; aluminum silicate, Langfang Fengderun Chemical Co., Ltd.

[0034] Wetting and disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com