Continuous flow rotating shaft reactor and application thereof

A rotating shaft and reactor technology, applied in chemical/physical/physical-chemical stationary reactors, chemical methods for reacting liquids with liquids, and chemical methods for reacting liquids with gaseous media, etc. The influence of particle size and distribution, unsuitable for small processing enterprises, inability to mix and react materials, etc., to achieve the effect of simple structure and operation, large specific gravity, and easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

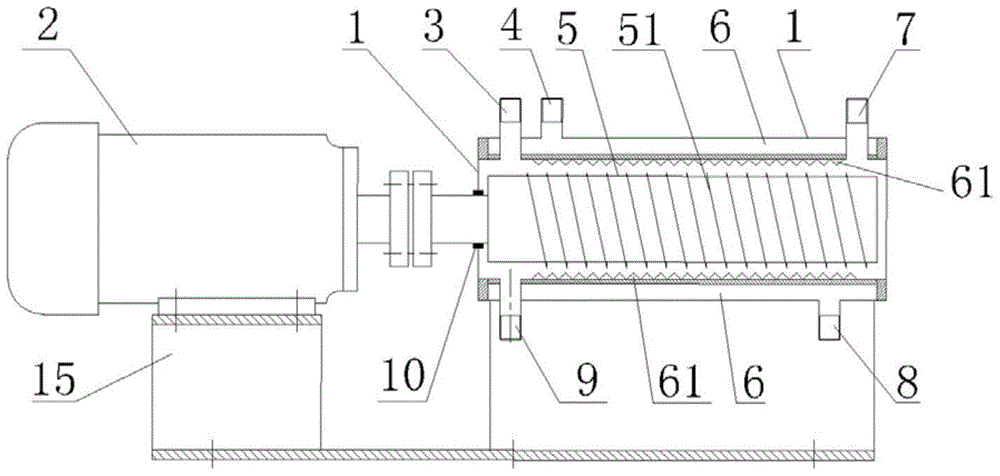

[0037] A continuous flow rotating shaft reactor, comprising a power unit 2 and a reactor body;

[0038] The power unit 2 is a motor;

[0039] The reactor body includes a shell 1, a jacket 6 and a rotating shaft 5. A jacket 6 is set inside the housing 1, and the jacket 6 surrounds the rotating shaft 5. The space between the rotating shaft 5 and the jacket 6 is The cavity is a reaction space 50;

[0040] A first material inlet 3 is provided on the upper part of the housing 1 close to the power device 2, a second material inlet 9 is provided on the symmetrical lower part, and a product outlet 7 is provided on the upper part of the housing 1 away from the power device 2;

[0041] The rotating shaft 5 is connected to the output shaft of the power unit 2; the rotating shaft 5 is installed horizontally; and the reactor and the power unit are all arranged on the support 15;

[0042] The 5-axis surface of the rotating shaft is smooth;

[0043] A seal 10 is provided between the rotat...

Embodiment 2

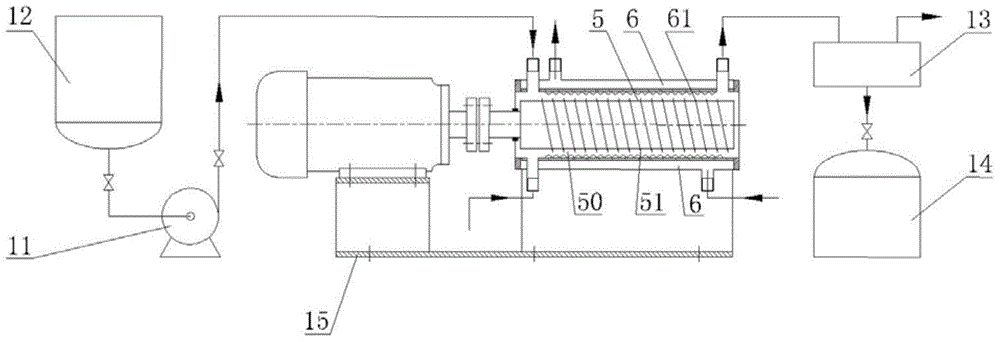

[0049] see figure 2 Shown, the application of a kind of continuous flow rotary axis reactor of the present invention in multiphase flow reaction process, with gas-liquid reaction LiOH and CO 2 Reaction produces Li 2 CO 3 For example:

[0050] The ratio of the length of the rotating shaft to the radius of the cross section used in the experiment is 10:1, and the rotating shaft reactor with a cavity volume of 50 L puts the LiOH solution in the raw material tank 12, and the solution will be pumped into the tank at 20 L / h with a volume of In the chamber of the 50L rotating shaft reactor, the pH value is adjusted to 9, and the CO 2The gas is passed into the cavity of the rotating shaft reactor, and the speed of the rotating shaft is adjusted to 500 rpm. The gas and liquid are fully contacted under the action of the guide thread of the rotating shaft, and the mixed precipitate is passed into a centrifuge for dehydration and washing, and then passed into a drying tank to adjust ...

Embodiment 3

[0052] see figure 2 Shown, the application of a kind of continuous flow rotary axis reactor of the present invention in multiphase flow reaction process, with gas-liquid reaction LiOH and CO 2 Reaction produces Li 2 CO 3 as an example

[0053] The ratio of the length of the rotating shaft to the radius of the cross-section used in the experiment is 10:1, and the rotating shaft reactor with a cavity volume of 50L puts the LiOH solution in the raw material tank, and the solution will be pumped into the 50L reactor at a rate of 12L / h by the action of the pump. In the cavity of the rotating shaft reactor, the pH value is adjusted to 10, and at the same time, the CO 2 The gas is passed into the chamber of the rotating shaft reactor, and the speed of the rotating shaft is adjusted to 400rpm. The gas and liquid are fully contacted under the action of the guide thread of the rotating shaft, and the mixed precipitate is passed into a centrifuge for dehydration and washing, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com