Purification process of pyrolysis carbon black of waste tire

A purification process, carbon black technology, applied in the direction of fibrous fillers, etc., can solve the problems of difficulty in ash content, inability to recover carbon black for reuse, and restrict the economical efficiency of recovery process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

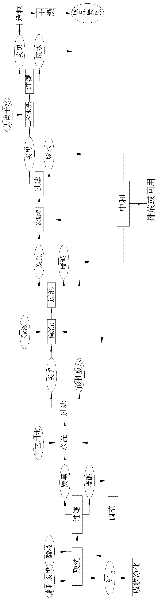

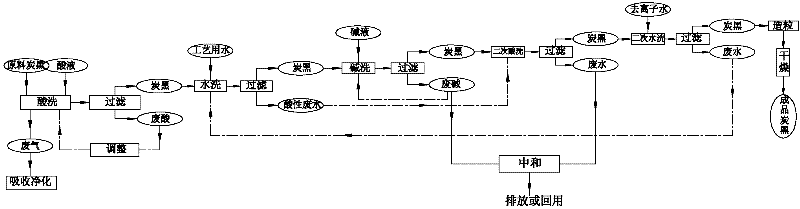

[0020] A carbon black purification process, its concrete steps mainly comprise:

[0021] (1) One pickling: Add cracking carbon black crushed to 400 meshes and 10% nitric acid solution into the reactor according to the solid-to-liquid ratio of 1:8 (kg:L), stir at 50°C for 30min, and filter; The gas is absorbed with lye;

[0022] (2) Washing with water The carbon black after pickling and filtering is mixed with water (total hardness 87mg / L) in a ratio of 1:10 (kg:L) by solid-liquid ratio, stirred for 10min, filtered, and the filtrate is used for subsequent use;

[0023] (3) Alkali washing The carbon black after washing and filtering is mixed with the sodium hydroxide solution of 1mol / L in a solid-to-liquid ratio of 1:8 (kg:L), stirred for 10min, and filtered;

[0024] (4) Secondary pickling, the filtrate of step (2) is fully mixed and stirred for 10min with the carbon black after alkali washing and filtration, and filters;

[0025] (5) Secondary water washing The carbon black ...

Embodiment 2

[0028] A carbon black purification process, its concrete steps mainly comprise:

[0029] (1) One pickling: Add cracking carbon black crushed to 600 meshes and 15% nitric acid solution into the reactor according to the solid-to-liquid ratio of 1:12 (kg:L), stir at 70°C for 30min, and filter; The gas is adsorbed by activated carbon;

[0030] (2) Water washing The carbon black after pickling and filtering is mixed with water (total hardness 88mg / L) in a ratio of 1:10 (kg:L) by solid-liquid ratio, stirred for 10min, filtered, and the filtrate is used for subsequent use;

[0031] (3) Alkali washing The carbon black after washing and filtering is mixed with the potassium hydroxide solution of 1mol / L in a ratio of 1: 10 (kg: L) in a solid-to-liquid ratio, stirred for 10 min, and filtered;

[0032] (4) Secondary pickling, the filtrate of step (2) is fully mixed and stirred for 10min with the carbon black after alkali washing and filtration, and filters;

[0033] (5) Secondary water ...

Embodiment 3

[0036] A carbon black purification process, its concrete steps mainly comprise:

[0037] (1) One pickling: Add cracking carbon black crushed to 500 meshes and 12% nitric acid solution into the reactor according to the solid-to-liquid ratio of 1:9 (kg:L), stir at 60°C for 30min, and filter; The gas is absorbed with lye;

[0038] (2) Washing with water The carbon black after pickling and filtering is mixed with water (total hardness 85mg / L) in a ratio of 1:10 (kg:L) by solid-liquid ratio, stirred for 10min, filtered, and the filtrate is used for subsequent use;

[0039] (3) Alkali washing The carbon black after washing and filtering is mixed with the potassium hydroxide solution of 1mol / L in a solid-to-liquid ratio of 1:9 (kg:L), stirred for 10min, and filtered;

[0040] (4) Secondary pickling, the filtrate of step (2) is fully mixed and stirred for 10min with the carbon black after alkali washing and filtration, and filters;

[0041] (5) Secondary water washing The carbon bla...

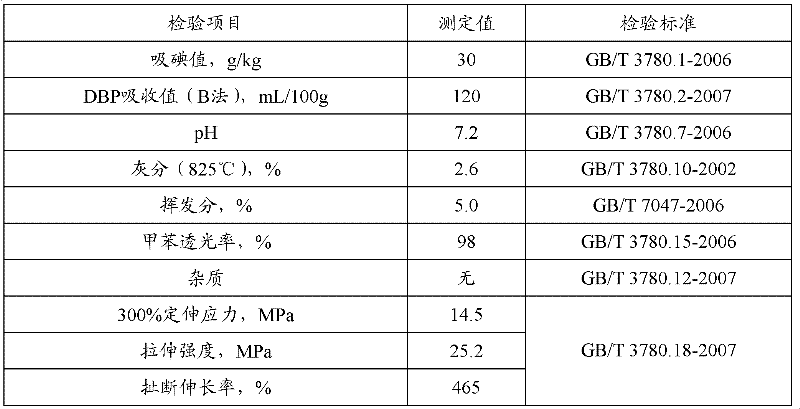

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com