Non-curing rubber asphalt waterproof material and preparation method thereof

A technology of asphalt waterproof material and non-curing rubber, which is used in building insulation materials, plastic recycling, bulk chemical production, etc., to avoid insufficient performance, good deformation requirements, and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

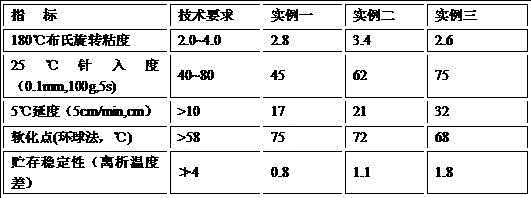

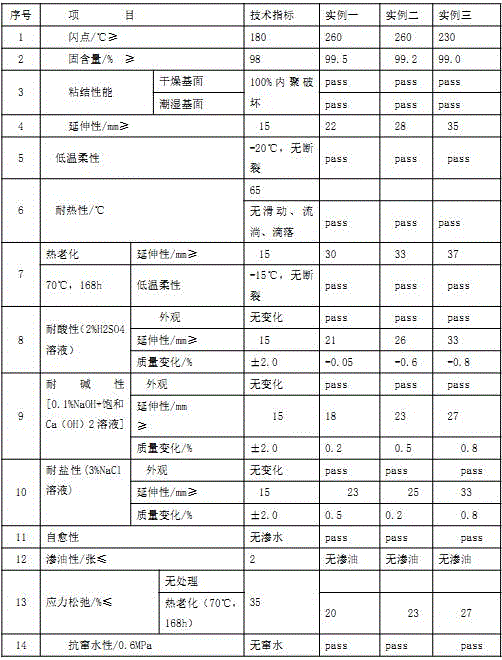

example 1

[0024] Example 1: Taking the production of 1000 kg of non-cured rubber asphalt waterproof material of the present invention as an example, each part is 10 kg, and the ratio of raw materials used is: 74.5 parts of basic asphalt, 16.5 parts of rubber powder, 0.25 parts of desulfurizing agent, and 1 part of composite modifier. 1 part of softener, 0.25 part of cross-linking agent, 6.5 parts of filler, wherein the base asphalt is heavy traffic 70# petroleum asphalt, the rubber powder specification is 60 mesh waste tire rubber powder for bias tires, and the desulfurizer is pentachlorothiophenol , the composite modifier is SBS, the softener is pine tar, the crosslinking agent is tetramethylthiuram disulfide, and the filler is 1250 mesh light calcium carbonate; the following steps are adopted during specific production:

[0025] (1) Measure the hot-melt asphalt into the mixing tank with heating system, and put the weighed waste tire rubber powder, softener, compound modifier and desulf...

example 2

[0028] Example 2: Take the production of 1000 kg of non-cured rubber asphalt waterproof material of the present invention as an example, each part is 10 kg, and the raw material ratio used is: 63 parts of basic asphalt, 21 parts of waste tire rubber powder, 0.67 parts of desulfurizing agent, compound modification 1.26 parts of softening agent, 4.2 parts of softening agent, 1.3 parts of cross-linking agent, 8.53 parts of filler, wherein base pitch is 110# petroleum pitch, and the selection and preparation method of all the other raw materials are the same as example one.

example 3

[0029] Example 3: Take the production of 1000 kg of non-curing rubber asphalt waterproof material of the present invention as an example, each part is 10 kg, and the raw material ratio used is: 54.4 parts of basic asphalt, 27.2 parts of waste tire rubber powder, 0.816 parts of desulfurizing agent, compound modified 0.816 parts of softening agent, 2.86 parts of softening agent, 1.63 parts of crosslinking agent, and 12.278 parts of filler, wherein base asphalt is crude oil catalytic oil slurry, rubber powder is 30 mesh bias tire rubber powder, and the selection and preparation method of all the other raw materials are the same as example one.

[0030] The non-cured rubber asphalt waterproof material of the present invention has the following characteristics:

[0031] (1) Adaptability to structural deformation: The non-curing rubber asphalt material itself has excellent ductility and cohesiveness, and can adapt to the deformation and cracking of the pavement base layer and the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com