Pipe type bridge floor flat pull cable bridge

A tubular and steel tube technology, applied in the field of tubular deck flat-stayed cable bridges, can solve problems such as the adverse impact of anti-corrosion treatment on the environment, limit the popularization and application of flat-stayed cable bridges, and frequently replace bridge decks, so as to reduce the maintenance workload. and cost, improve driving stability and safety, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

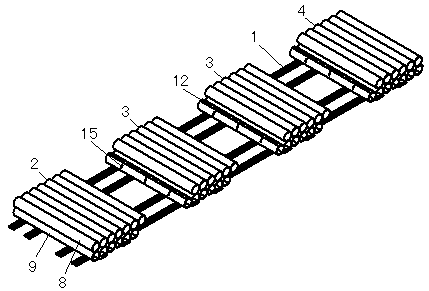

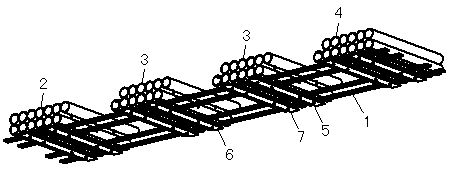

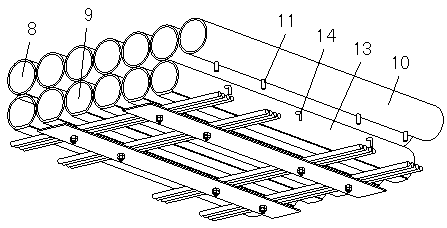

[0025] This example picture 1 ~ picture 8 As shown, it consists of a number of standard steel pipes and special-shaped steel pipes juxtaposed. Standard steel pipe as upper steel pipe 8 , special-shaped steel pipe as the lower steel pipe 9 . A number of standard steel pipes are welded side by side to form a plane as the bridge deck, that is, the centers of all standard steel pipes are located on a straight line when viewed from the cross section. Special-shaped steel pipe and steel cable 1 connect. There are two types of special-shaped steel pipes, one is located on the edge of the component and needs to be connected with adjacent components, such as the protruding steel pipe on the lower floor 17 and the extra steel pipes in the lower layer 18 , the other is located in the middle of the component and does not need to be connected with the remaining lower steel pipes connected to the adjacent components 9 . The rest of the lower steel pipe 9 Includes lower ...

Embodiment 2

[0028] This example picture 1 ~ picture 8 As shown, all the staples in the embodiment 11 Replace with hook 14 , while inserting all staple holes 12 Replaced with a hook hole 15 Composition Example 2 . due to hook 14 shape and staple 11 different, the corresponding hook hole 15 The shape of should also correspond to it.

Embodiment 1

[0030] Example 1 The connectors are staples 11 , Example 2 The connector is a hook 14 , during specific implementation, two kinds of connectors can also be used at the same time, which can be used as an example 3 。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com