Modified asphalt with heat storage stability and preparation method thereof

A modified asphalt and stability technology, which is applied in building components, building insulation materials, buildings, etc., can solve problems such as thermodynamic incompatibility, durability not meeting expectations, asphalt not meeting cohesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

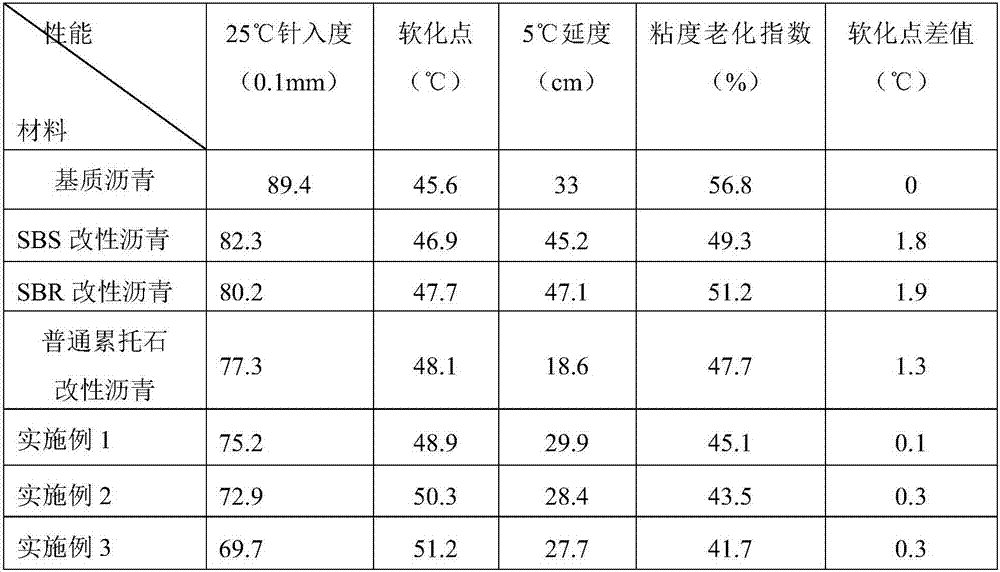

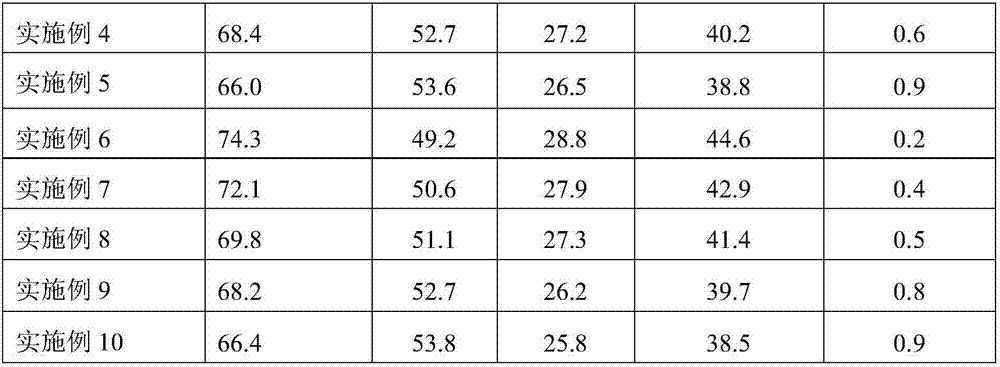

Examples

preparation example Construction

[0029] A preparation method of modified asphalt with thermal storage stability, specifically comprising the following steps:

[0030] First, heat the base asphalt to the molten state, add the composite additive at room temperature at a speed of 2000-3000r / min and stir evenly, then add the organic rectorite at 125-135°C, and then add the organic rectorite at 145-155°C at 3000- Shearing and stirring at a speed of 4000r / min for 1-2 hours, then adding a defoamer at a speed of 500-1000r / min and stirring evenly to obtain organic rectorite-modified asphalt.

[0031] Specifically, first heat the base asphalt to a molten state, add the composite additive at room temperature at a speed of 2000-3000r / min and stir for 3-5min; add a defoamer at a speed of 500-1000r / min and stir for 5-10min Finally, the organic rectorite modified asphalt is obtained.

[0032] Specifically, a stabilizer and a dispersant are sequentially added to the base asphalt.

[0033] Among them, the specific preparati...

Embodiment 1

[0035] Step 1: Take 500g of No. 90 petroleum asphalt and heat it to melt it completely, then add 0.5g of sulfur powder and 1g of sodium dodecylbenzene sulfonate with a particle size of 100 mesh to the molten asphalt at a speed of 2000r / min, and stir for 3 minutes until uniform, then add 5g of organic rectorite at 135°C, shear and stir at 145°C at a speed of 3000r / min for 1h, then add 0.25g of polydimethylsiloxane at a speed of 500r / min and After uniform stirring, the organic rectorite-modified asphalt is obtained.

Embodiment 2

[0037] Step 1: Take 500g of No. 90 petroleum asphalt and heat it to make it completely melted, then add 1g of sulfur powder and 2g of sodium dodecylsulfonate with a particle size of 90 mesh to the molten asphalt at a speed of 3000r / min, and stir for 5min until uniform , then add 10g of organic rectorite at 125°C, shear and stir at 155°C at a speed of 3000r / min for 2h, then add 0.4g of polyoxyethylene polyoxypropanolamine ether at a speed of 600r / min and After uniform stirring, the organic rectorite-modified asphalt is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com