Modified asphalt for pouring asphalt concrete and preparation method thereof

A technology of asphalt concrete and modified asphalt, which is applied to building components, building insulation materials, buildings, etc., to achieve the effects of high strength and stiffness modulus, improved high temperature performance, high softening point and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

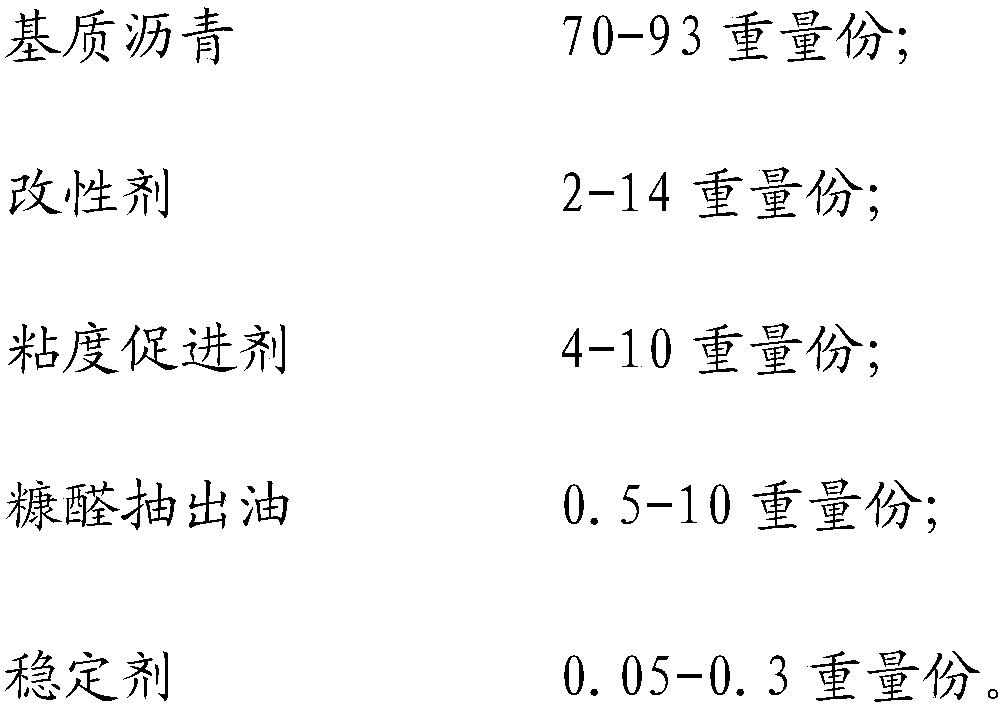

[0038] The present invention also provides a method for preparing the above-mentioned modified asphalt, comprising: A) taking a reaction kettle, adding 70-93 parts by weight of base asphalt at a temperature of 140-190 ° C into the reaction kettle, adding 2-14 parts by weight Parts of modifying agent is added in the reaction kettle, and high shear is performed for 20-90 minutes at 1000-5000 rpm;

[0039]B) After the modifier is fully swollen, add 0.5-10 parts by weight of furfural extract oil into the reaction kettle, and continue shearing for 5-30 minutes at 1000-5000 rpm;

[0040] C) Add 0.05-0.3 parts by weight of a stabilizer to the reactor, cut at a speed of 1000-5000 rpm for 30 minutes, add 4-10 parts by weight of a viscosity accelerator to the reactor, and continue shearing The modified asphalt was obtained in 60 minutes.

[0041] Wherein, the base asphalt, modifier, viscosity accelerator, furfural extraction oil and stabilizer are all the same as above, and will not be...

Embodiment 1

[0045] Add 85.85 parts by weight of base asphalt at a temperature of 180-190° C. into the reactor, add 6 parts by weight of a modifier into the reactor, and perform high shear at 2500 rpm for 60 minutes;

[0046] After the modifier is fully swollen, the furfural extract oil of 4 parts by weight is added in the reaction kettle, and the shearing is continued for 15 minutes at 2500 rpm;

[0047] When the temperature of the base asphalt in the reaction kettle is 170-180°C, add 0.15 parts by weight of stabilizer into the reaction kettle, cut at a speed of 2500 rpm for 30 minutes, and add 4 parts by weight of a viscosity accelerator, and continue shearing for 60 minutes to obtain the modified asphalt.

[0048] The modified asphalt obtained in Example 1 was tested for performance, and the results are shown in Table 1.

[0049] Table 1

[0050]

Embodiment 2

[0052] Add 77.75 parts by weight of base asphalt at a temperature of 180-190° C. into the reactor, add 10 parts by weight of a modifier into the reactor, and perform high shear at 3500 rpm for 60 minutes;

[0053] After the modifying agent is fully swollen, the furfural extract oil of 7 parts by weight is added in the reaction kettle, and the shearing is continued for 25 minutes at 3500 rpm;

[0054] When the temperature of the base asphalt in the reaction kettle is 170-180°C, add 0.25 parts by weight of stabilizer into the reaction kettle, cut at a speed of 2500 rpm for 30 minutes, and add 5 parts by weight of a viscosity accelerator, and continue shearing for 60 minutes to obtain the modified asphalt.

[0055] The modified asphalt obtained in Example 2 was tested for performance, and the results are shown in Table 2.

[0056] Table 2

[0057]

[0058] From the results of Example 1 and Example 2, it can be seen that the modified asphalt for pouring asphalt concrete provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com