Pavement hot-pouring crack pouring glue with storage stability and preparation method thereof

A technology of joint glue and hot pour, which is applied in the direction of adhesive, adhesive type, asphalt material adhesive, etc., can solve the problems such as the influence of joint glue road service performance, achieve enhanced thermal storage stability, improve relative Capacitance, effect of improving low temperature deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

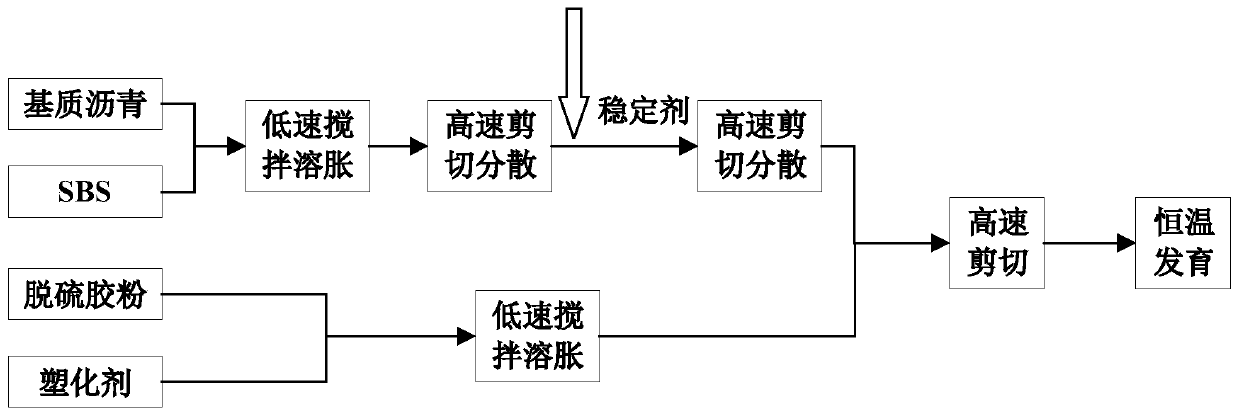

Method used

Image

Examples

specific Embodiment approach 1

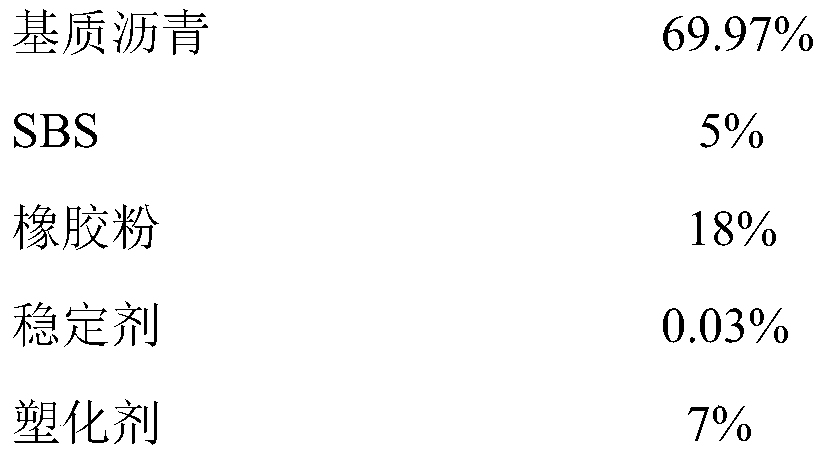

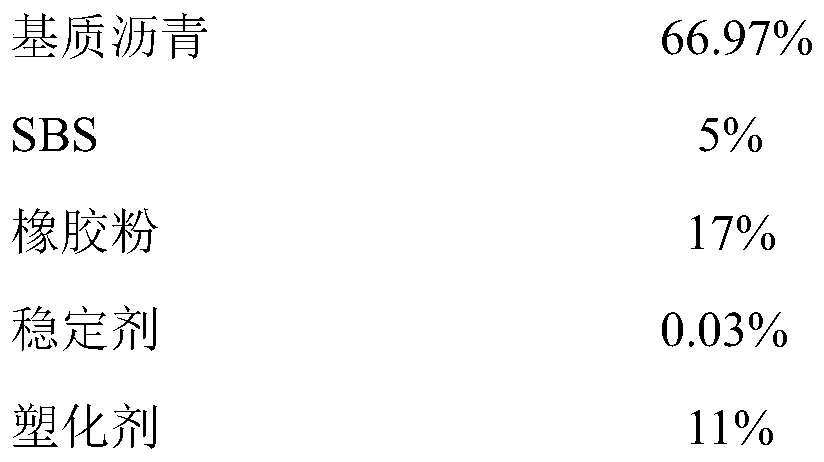

[0019] Specific embodiment 1: A kind of road surface hot-filling joint-filling glue with stable storage described in this embodiment, said road-surface hot-filling joint-filling glue is composed of 60% to 70% of base asphalt, 3 %~6% of SBS (ie styrene-butadiene-styrene ternary block copolymer), 12%~20% of rubber powder, 0.02%~0.04% of stabilizer and 6%~20% of plastic Chemical composition.

[0020] The base asphalt can choose the corresponding grade according to the climate zone used, preferably grade A asphalt of various grades;

[0021] The SBS, that is, styrene-butadiene-styrene ternary block copolymer, is preferably YH-791 type, star type, linear type or mixed type in any proportion.

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that: the base asphalt is residual oil, straight-run asphalt, deoiled asphalt or blended asphalt.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 2 in that: the rubber powder is desulfurized waste tire rubber powder.

[0024] The size of the desulfurized rubber powder is between 20-60 mesh, preferably 30-40 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com