Chemical reaction type sbs modified asphalt heat storage stabilizer and preparation method thereof

A thermal storage stabilizer, chemical reaction type technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., to achieve long-term thermal storage stability, ensure thermal storage stability, improve aging resistance and The effect of high and low temperature pavement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

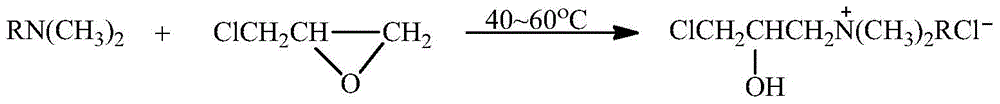

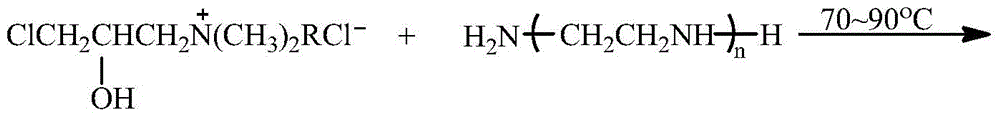

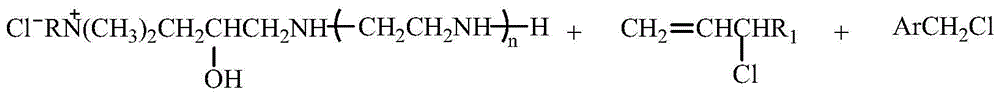

Method used

Image

Examples

Embodiment 1

[0035] Preparation of stabilizer

[0036] Add 21.3g (0.1mol) of dodecyldimethyl tertiary amine and 30.0g of methanol into the reaction vessel, add 11.0g (0.11mol) of 98% sulfuric acid under stirring, mix well, heat up to 45°C, drop Add 10.2g (0.11mol) of epichlorohydrin, control the rate of addition so that the reaction temperature is always below 55°C, stir and react at 45-55°C for 5 hours, then add 16.1g (0.11mol) of triethylenetetramine, After stirring and reacting for 6 hours, add 9.2g (0.12mol) 3-chloropropene, 25.5g (0.2mol) benzyl chloride, stir and react at 70-75°C for 6 hours, distill methanol, transfer the reaction product while it is hot, and dry it After crushing to more than 300 mesh, the stabilizer product is obtained.

[0037] Preparation of modified asphalt 500.0g brand is SK-70 # Heat the petroleum asphalt to 160°C, add 20.0g of star-shaped SBS and 5.0g of the above stabilizer, shear at this temperature for 30 minutes at a low speed, then heat up to 180°C, a...

Embodiment 2

[0041] Preparation of stabilizer

[0042] Add 24.1g (0.1mol) tetradecyldimethyl tertiary amine and 30.0g ethanol into the reaction vessel, add 11.2g (0.11mol) 36% hydrochloric acid under stirring, after mixing uniformly, heat up to 50°C, drop Add 11.1g (0.12mol) of epichlorohydrin, control the rate of addition to keep the reaction temperature at 50-55°C, stir and react at this temperature for 5.5h, then add 11.3g (0.11mol) of diethylenetriamine, at 75-80 After stirring and reacting for 6 hours at ℃, add 10.0g (0.11mol) 3-chloro-1-butene and 17.6g (0.12mol) p-methoxybenzyl chloride, stir and react at 70-75℃ for 6 hours, then distill off ethanol, Transfer the reaction product while it is hot, dry it and crush it to a size larger than 300 mesh to obtain the stabilizer product.

[0043] Preparation of SBS Modified Asphalt

[0044] Same example 1

[0045] Performance test of SBS modified asphalt

[0046] The results of the same example 1 are shown in Table 2

Embodiment 3

[0048] Preparation of stabilizer

[0049] Add 29.7g (0.1mol) of octadecyldimethyl tertiary amine and 40.0g of isopropanol into the reaction vessel, add 11.2g (0.11mol) of 36% hydrochloric acid under stirring, stir and mix well, then heat up to 50 ℃, add 11.1g (0.12mol) epichlorohydrin dropwise, control the rate of addition to keep the reaction temperature at 55-60℃, and stir the reaction at this temperature for 6h, then add 6.6g (0.11mol) ethylenediamine, and heat up to 70~75°C, after stirring and reacting at this temperature for 6h, add 8.4g (0.11mol) 3-chloropropene, 7.6g (0.06mol) benzyl chloride and 9.0g (0.11mol) chloroethanol, at 80~85°C After stirring and reacting for 6 hours, the isopropanol was evaporated, the product was transferred while it was hot, dried and crushed to a size larger than 300 mesh to obtain the stabilizer product.

[0050] Preparation of SBS Modified Asphalt

[0051] Same example 1

[0052] Performance test of SBS modified asphalt

[0053] The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com