Modified asphalt binder and preparation method and application thereof

A technology of modified asphalt and binder, applied in building insulation materials, building components, buildings, etc., can solve the problems of segregation, engineering hazards, uneven distribution of waste tire powder and matrix asphalt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0078] A kind of montmorillonite modified sulfur, each component and its corresponding weight are as shown in table 1, and make through the following steps:

[0079] a. Stir and mix montmorillonite and water for 30 minutes at 25°C and 120 r / min to obtain suspension A;

[0080] b. Add coupling agent to suspension A and grind to obtain suspension B;

[0081] c. Add sulfur to suspension B, stir and mix at 25°C and 200r / min for 60min, then dry at 80°C for 4h, pulverize, and pass through a 200-mesh sieve to obtain montmorillonite-modified sulfur.

[0082] Wherein, the montmorillonite is calcium-based montmorillonite, the water is industrial water, and the coupling agent is silane coupling agent KH-560.

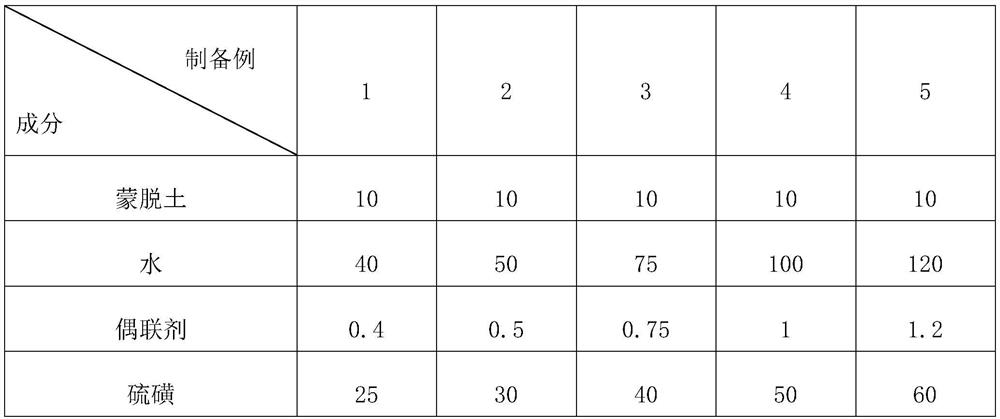

preparation example 2-5

[0084] A montmorillonite-modified sulfur, which differs from Preparation Example 1 in that each component and its corresponding weight are shown in Table 1.

[0085] Each component and its weight (kg) in table 1 preparation example 1-5

[0086]

preparation example 6

[0088] A montmorillonite-modified sulfur, which differs from Preparation Example 3 in that the montmorillonite is sodium-based montmorillonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com