Process for preparing SBS modified asphalt

A technology for modified asphalt and matrix asphalt, which is applied in the chemical processing of tar asphalt/petroleum asphalt/natural asphalt, building components, building insulation materials, etc. , recovery of high energy consumption, to achieve the effect of improving compatibility, easy operation, poor thermal storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

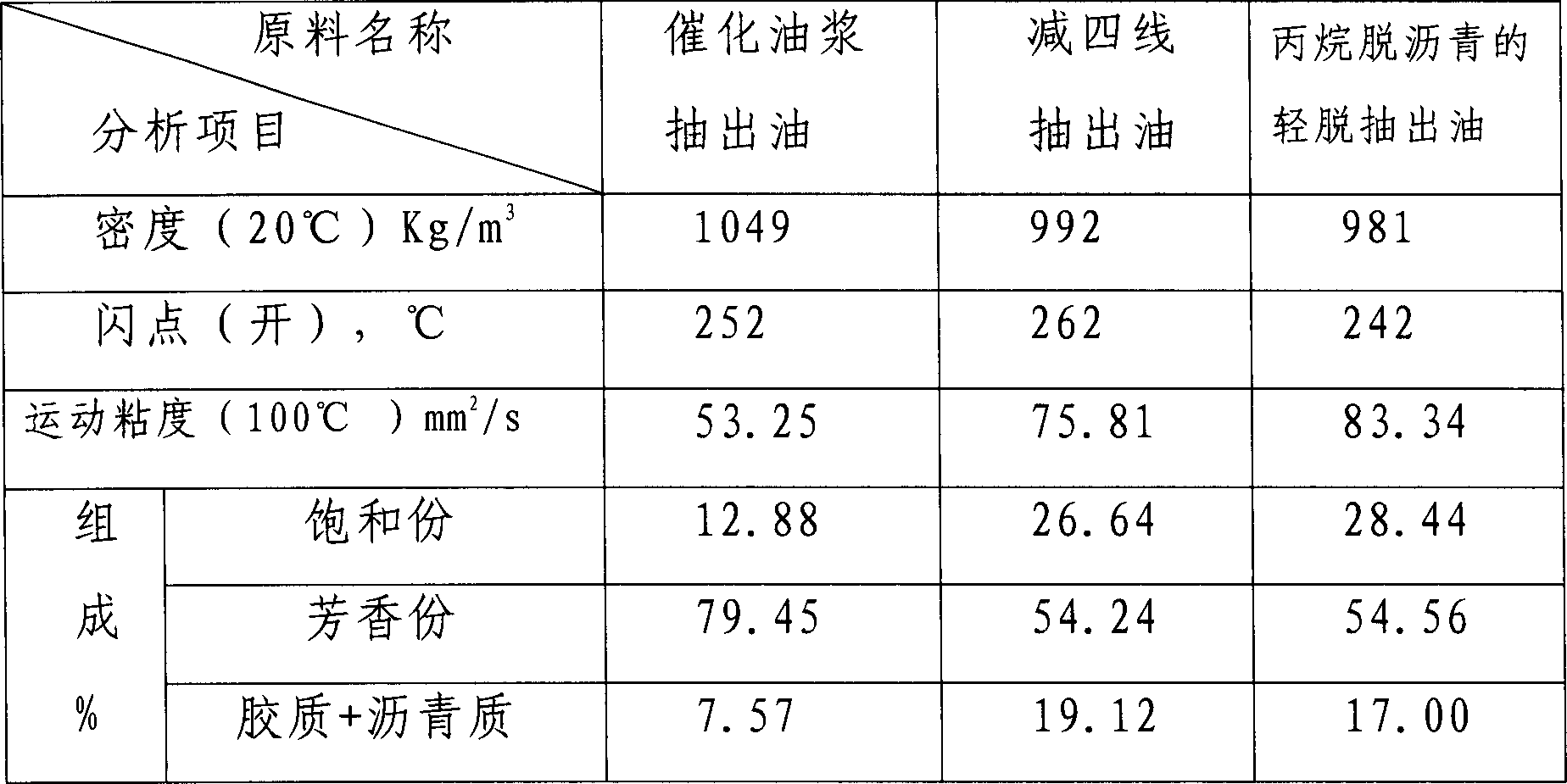

[0017] Example 1 In a container with a stirrer, weigh 90 g of peptizer minus four-line extracted oil, 30 g of styrene-butadiene-styrene thermoplastic elastomer produced by Yueyang Petrochemical Company, and stir at 160 ° C for 4.5 h, Make a mortar mother liquor containing 25% SBS, then mix the mother liquor with 480g of base asphalt under stirring conditions at 160°C, heat up after mixing and stir at 210°C±5°C for 2.5h to obtain a uniform and stable colloidal structure SBS modified asphalt products.

[0018] See Table 2 for the formulations of Examples 1-5; see Table 3 for the property analysis of modified asphalt products of Examples 1-5.

[0019] sample

[0020] Sample

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com